Electromagnetic pump for pumping liquid brazing filler metal

A liquid metal and electromagnetic pump technology, applied in the field of electromagnetic pumps, can solve the problems of large and complex equipment, redundant device systems, and occupied space, and achieve the effect of avoiding complex devices and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below, the present invention will be described in detail with reference to the drawings and embodiments.

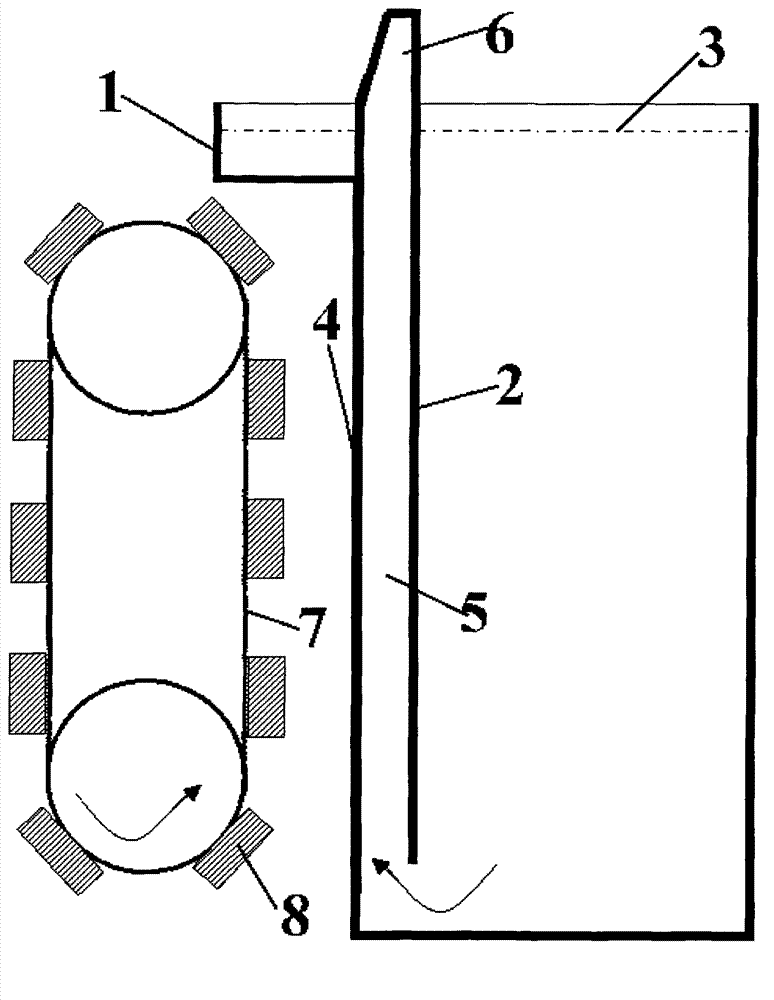

[0010] The electromagnetic pump has a solder tank 1 for accommodating liquid metal solder. An iron plate 2 extending from the top to the bottom is arranged in the solder tank 1. The bottom of the iron plate 2 and the bottom of the solder tank 1 have a The gap through which the liquid metal solder 3 passes, the iron plate 2 and the tank wall 4 of the solder tank 1 form a flow channel 5 for the liquid metal solder 3, and extend to the top of the solder tank 1 to finally form a nozzle for the liquid metal solder 3 6; a conveyor belt 7 is arranged at the position adjacent to the flow channel 5 outside the solder tank 1, and a plurality of permanent magnets 8 are arranged at intervals on the conveyor belt 7, and a motor (not shown) drives the conveyor belt 7 to move upwards, thereby generating upward movement Magnetic field, and correspondingly generate an upward thrust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com