Imaging lens

一种摄像透镜、透镜的技术,应用在光学元件、光学、仪器等方向,能够解决很难小型轻量化与光学性能提高等问题,达到实现小型轻量化、制造性提高、提高制造性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

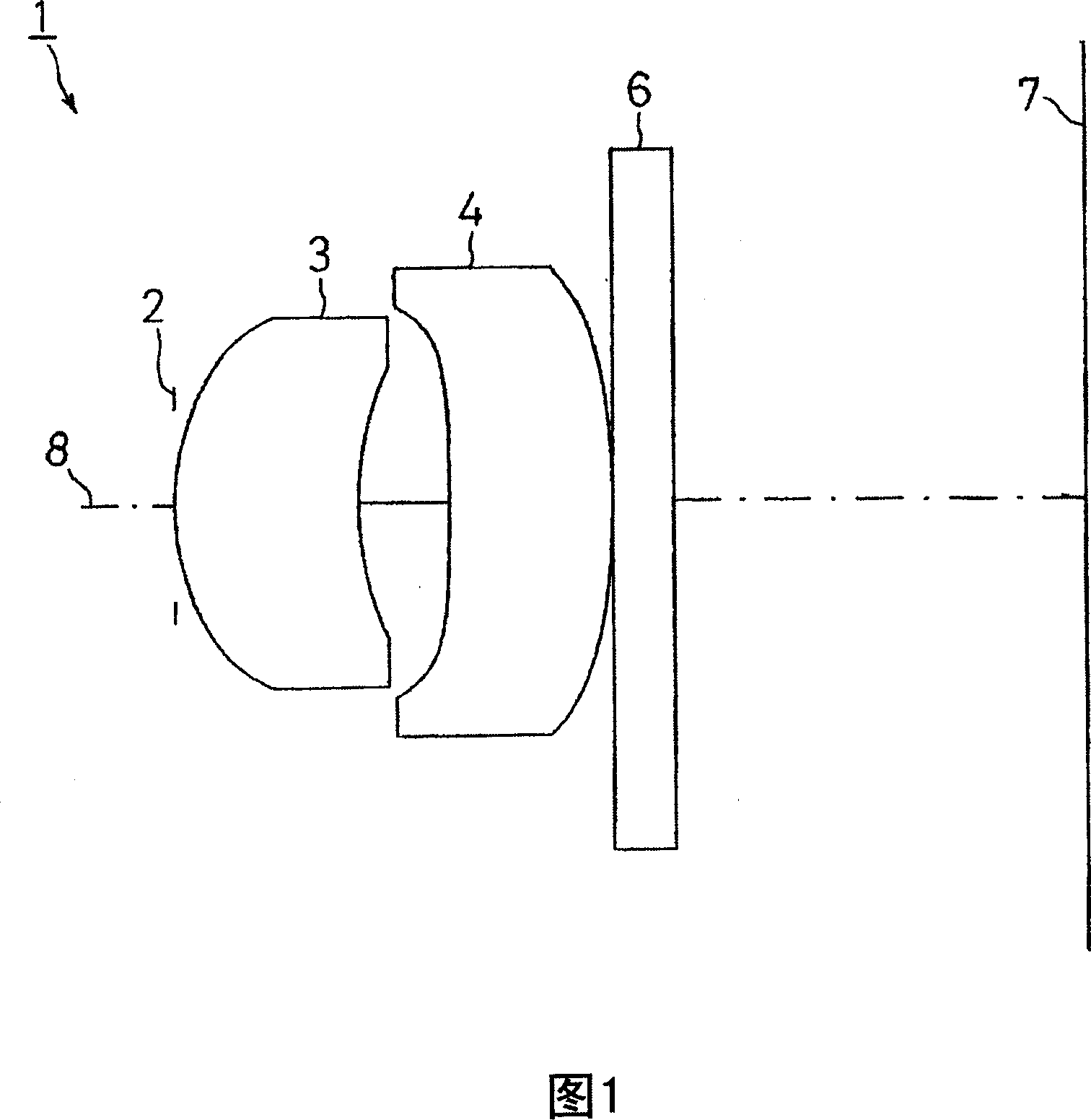

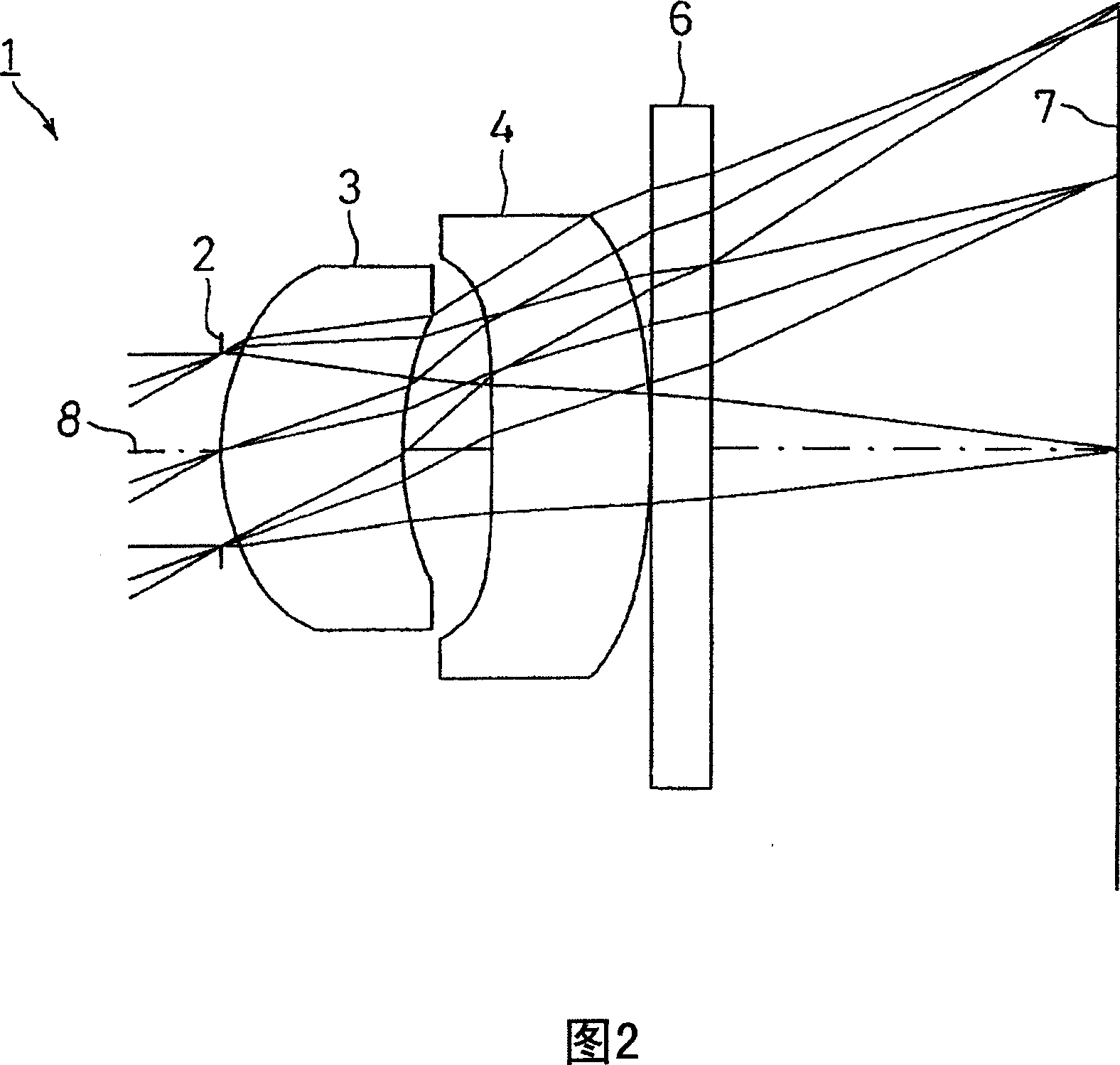

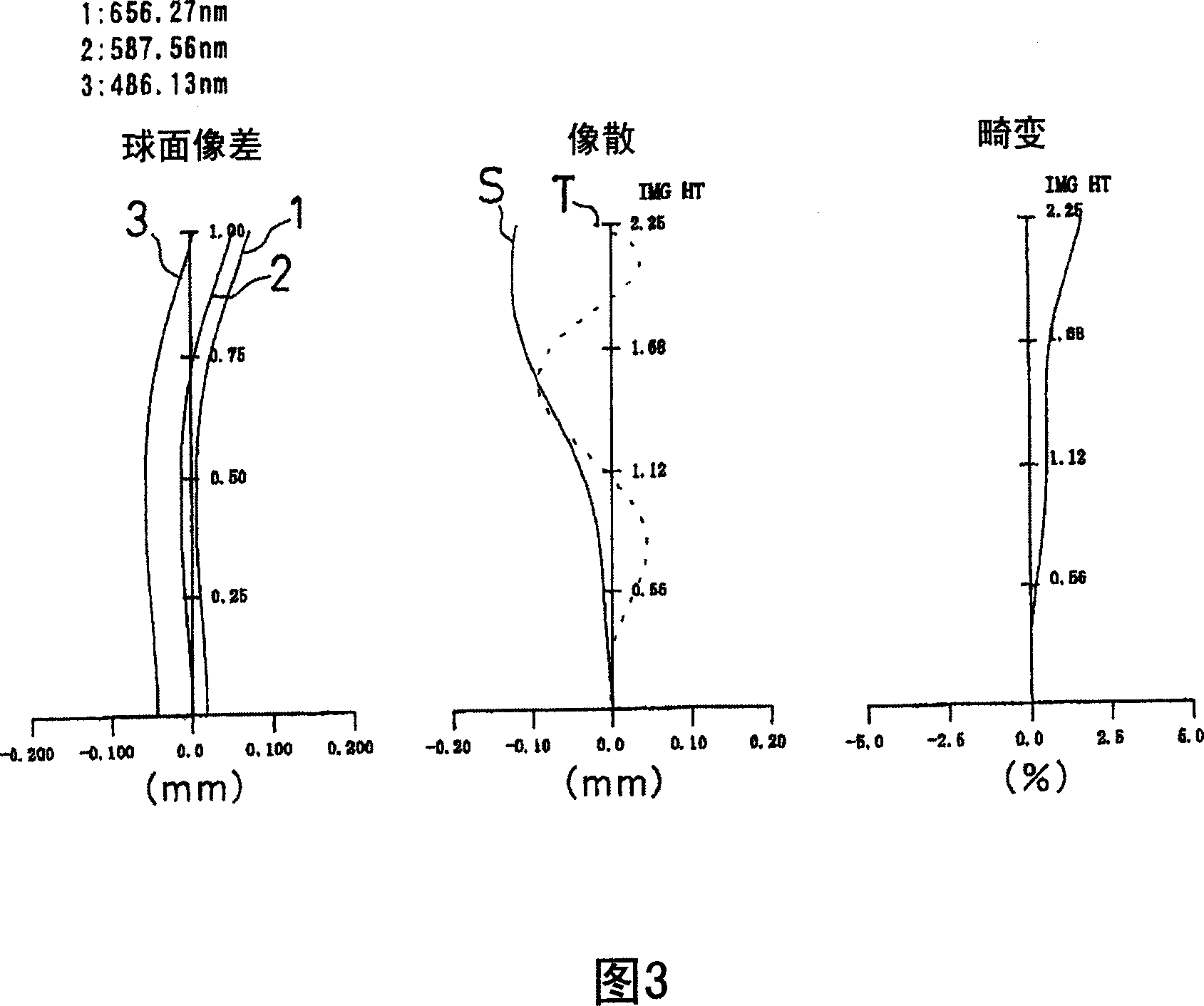

[0168] FIG. 2 shows a first embodiment of the present invention. In this embodiment, an iris diaphragm 2 is disposed on the object side of the first surface of the first lens 3 similarly to the imaging lens 1 having the structure shown in FIG. 1 , and A cover glass as a filter 6 is disposed between the second surface of the second lens 4 and the imaging surface 7 . In addition, the iris 2 is arranged at the same position in the direction of the optical axis 8 as the point on the optical axis 8 of the first surface of the first lens 3 .

[0169] The imaging lens 1 of this first embodiment is set by the following conditions.

[0170] lens data

[0171] L=4.34mm, fl=3.85mm, f 1 =5.18mm, f 2 =8.42mm, d 1 = 0.9 mm, d 2 =0.44mm, d 3 =0.8mm, Fno=4.0

[0172] Surface number r d nd υd

[0173] (part)

[0174] 1 (Iris diaphragm) 0.000 0.00

[0175] 2 (first surface of the first lens) 1.270 0.90 1.531 56.0

[0176] 3 (first lens second surface) 1.778 0.44

[0177] 4 (Second l...

no. 2 example

[0191] FIG. 4 shows a second embodiment of the present invention. In this embodiment, an iris diaphragm 2 is arranged on the object side of the first surface of the first lens 3 similarly to the imaging lens 1 having the structure shown in FIG. 1 , and A cover glass as a filter 6 is disposed between the second surface of the second lens 4 and the imaging surface 7 . In addition, the iris 2 is arranged at the same position in the direction of the optical axis 8 as the point on the optical axis 8 of the first surface of the first lens 3 .

[0192] The imaging lens 1 of this second embodiment is set by the following conditions.

[0193] lens data

[0194] L=2.19mm, fl=1.94mm, f 1 =2.7mm, f 2 =3.91mm, d 1 = 0.48mm, d 2 = 0.2mm, d 3 =0.4mm, Fno=4.0

[0195] Surface number r d nd υd

[0196] (part)

[0197] 1 (Iris diaphragm) 0.000 0.00

[0198] 2 (first surface of the first lens) 0.645 0.48 1.531 56.0

[0199] 3 (first lens second surface) 0.870 0.20

[0200] 4 (Second ...

no. 3 example

[0214] FIG. 6 shows a third embodiment of the present invention. In this embodiment, an iris diaphragm 2 is disposed on the object side of the first surface of the first lens 3 similarly to the imaging lens 1 having the structure shown in FIG. 1 , and A cover glass as a filter 6 is disposed between the second surface of the second lens 4 and the imaging surface 7 . In addition, the iris 2 is arranged at the same position in the direction of the optical axis 8 as the point on the optical axis 8 of the first surface of the first lens 3 .

[0215] The imaging lens 1 of this third embodiment is set by the following conditions.

[0216] lens data

[0217] L=2.09mm, fl=1.86mm, f 1 =2.37mm, f 2 =4.55mm, d 1 = 0.5mm, d 2 =0.18mm, d 3 =0.4mm, Fno=4.0

[0218] Surface number r d nd υd

[0219] (part)

[0220] 1 (Iris diaphragm) 0.000 0.00

[0221] 2 (first surface of the first lens) 0.625 0.50 1.525 56.0

[0222] 3 (first lens second surface) 0.909 0.18

[0223] 4 (Second le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com