Elevating conveyance device

A technology of conveying device and lifting drive mechanism, which is applied in the direction of lifting device, lifting frame, transportation and packaging, etc., which can solve the problems of rising equipment cost, lack of versatility, and inability to use flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

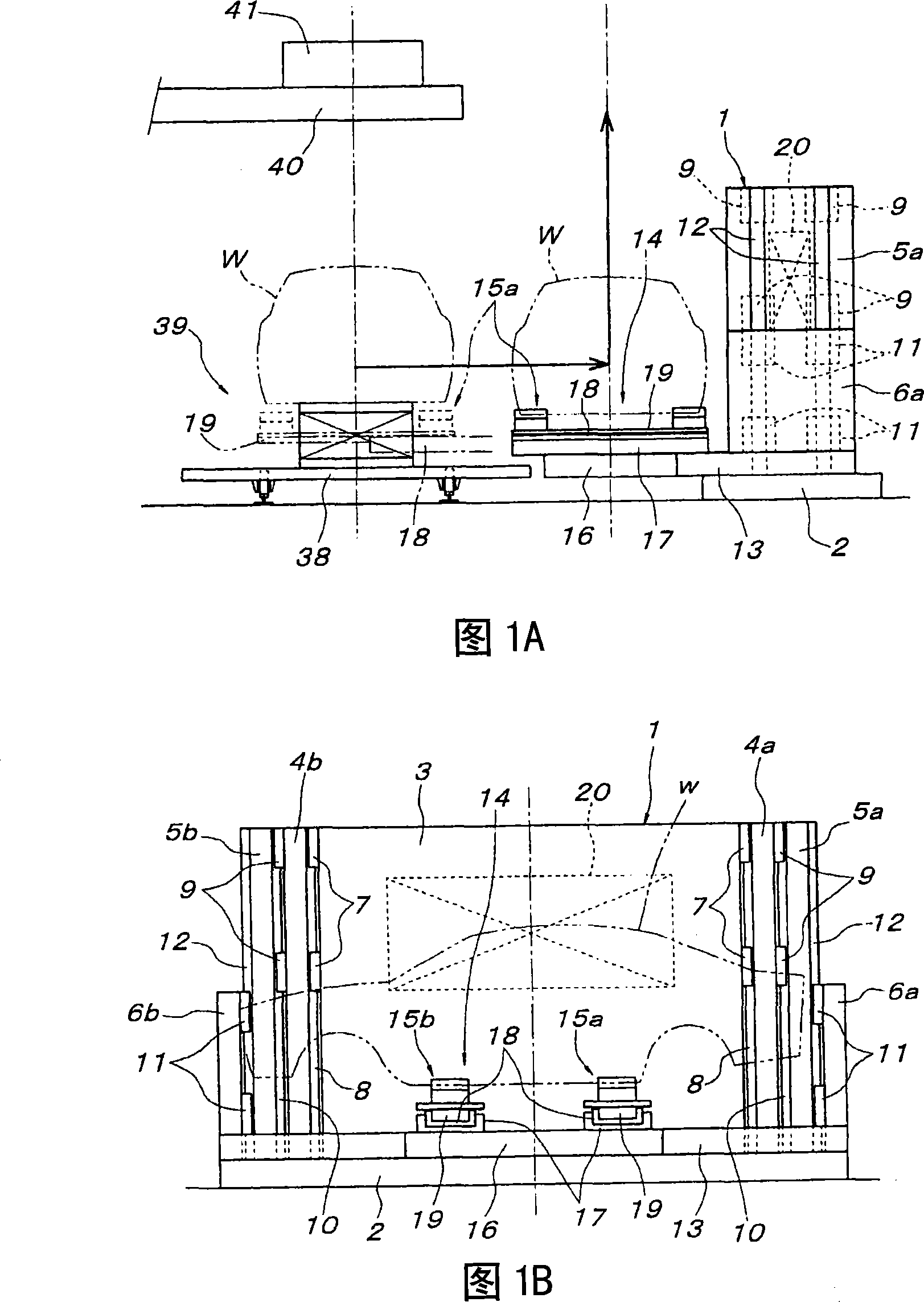

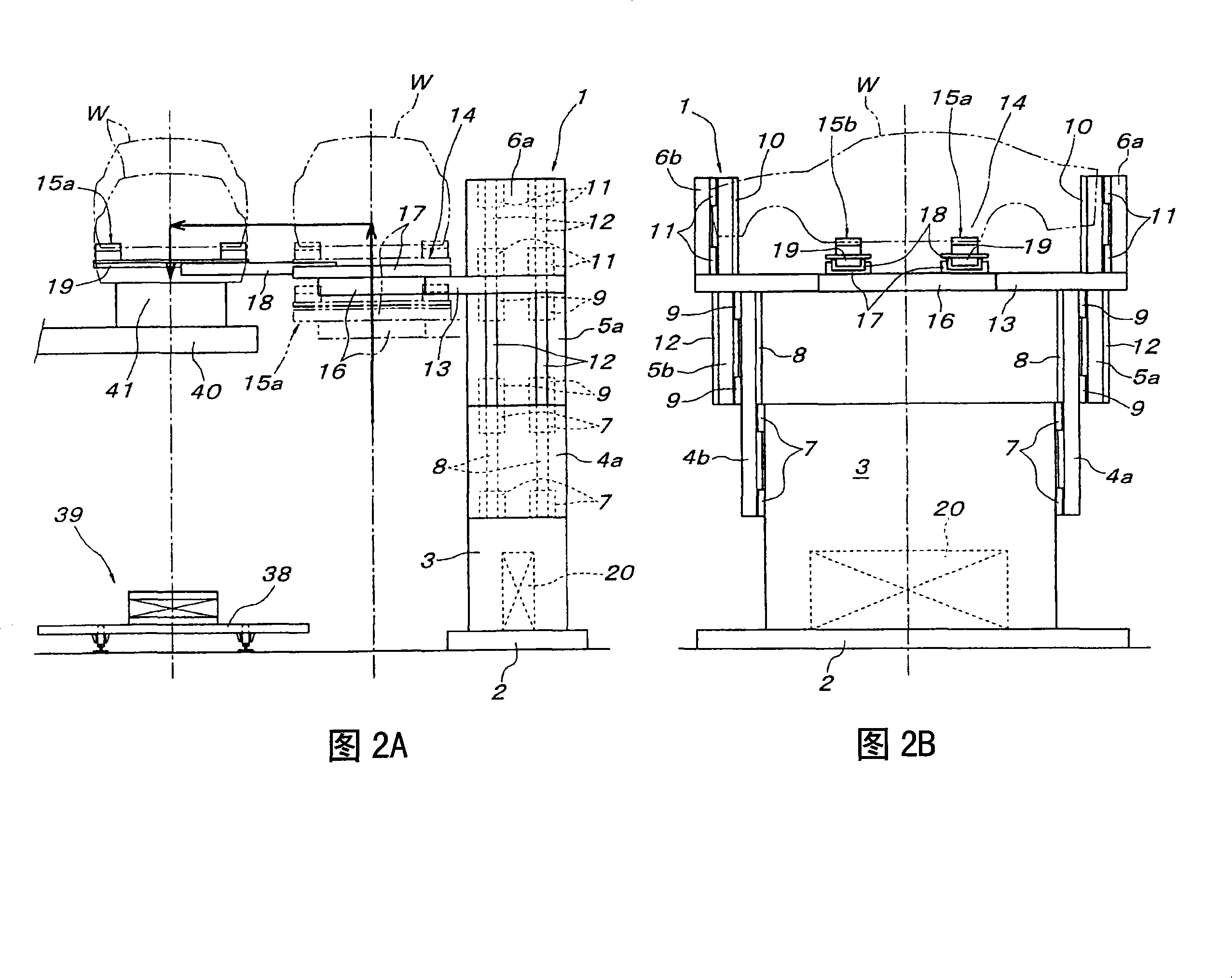

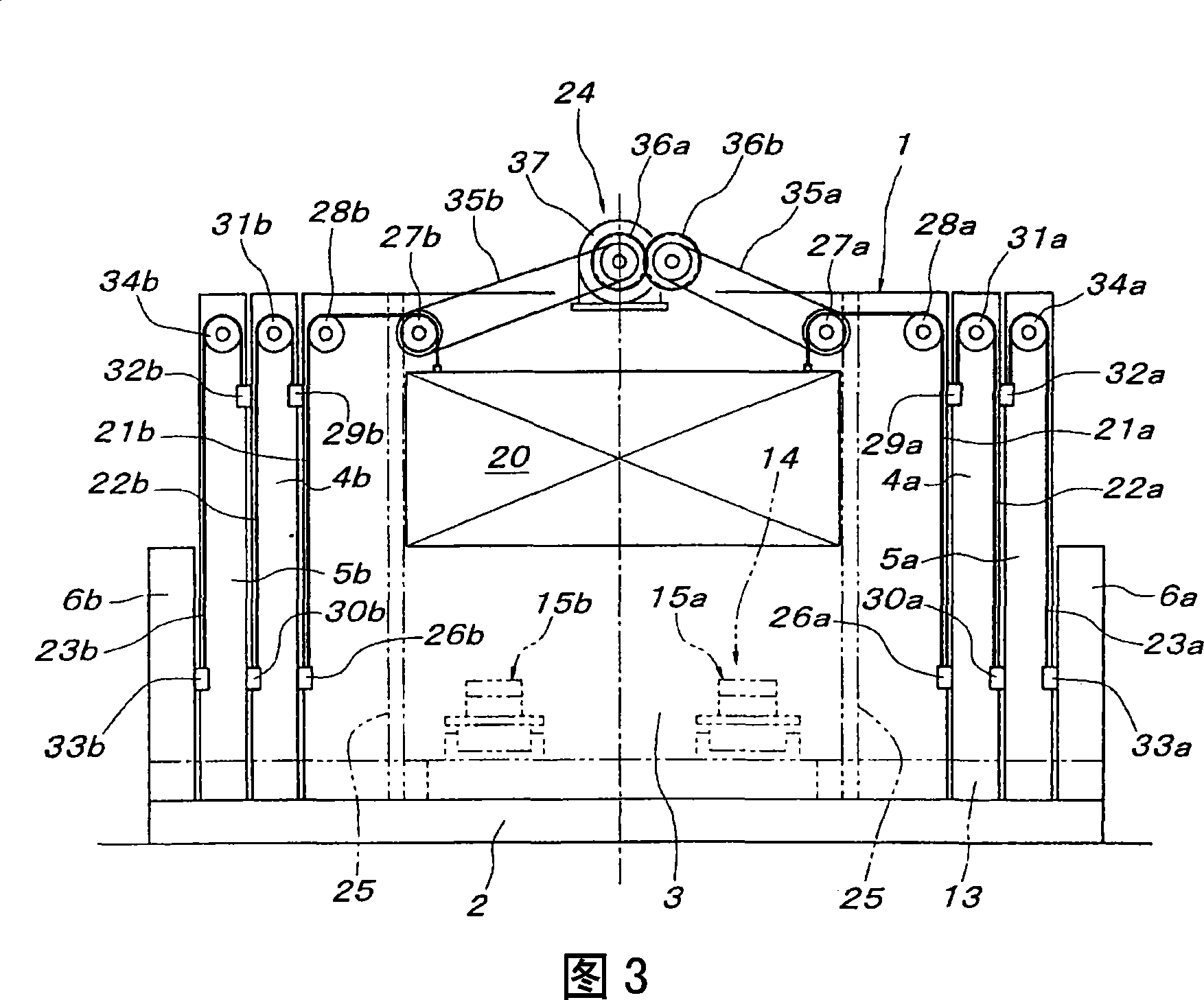

[0043] Below, according to Fig. 1~Fig. 3, the first embodiment when the present invention is implemented as a transfer device is described, and the reference number 1 represents a multi-section telescopic strut body, which is erected on the floor surface and fixed by an anchor or the like on the base 2. Fixed pillar portion 3; a pair of left and right first middle section lifting pillar portions 4a, 4b supported on the left and right sides of the fixed pillar portion 3 in a liftable manner; A pair of left and right middle section lifting support parts 5a, 5b on the outside of the pillar parts 4a, 4b; a pair of left and right bottom joint lifting parts 6a, 6b constitutes. The planar shape of the fixed pillar portion 3 is a rectangular column shape that is long in the lateral direction.

[0044] The elevating and guiding mechanism of each elevating strut portion 4a-5b and the last elevating portion 6a, 6b can be arbitrary, but, in this embodiment, a pair of left and right first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com