Sheet hole punching apparatus and sheet hole punching method

A technology of perforating device and paper, applied in metal processing and other directions, can solve the problems of slowing down the perforation speed, increasing the load of the driving motor, and increasing the device of the driving part, so as to achieve the effect of fast perforation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

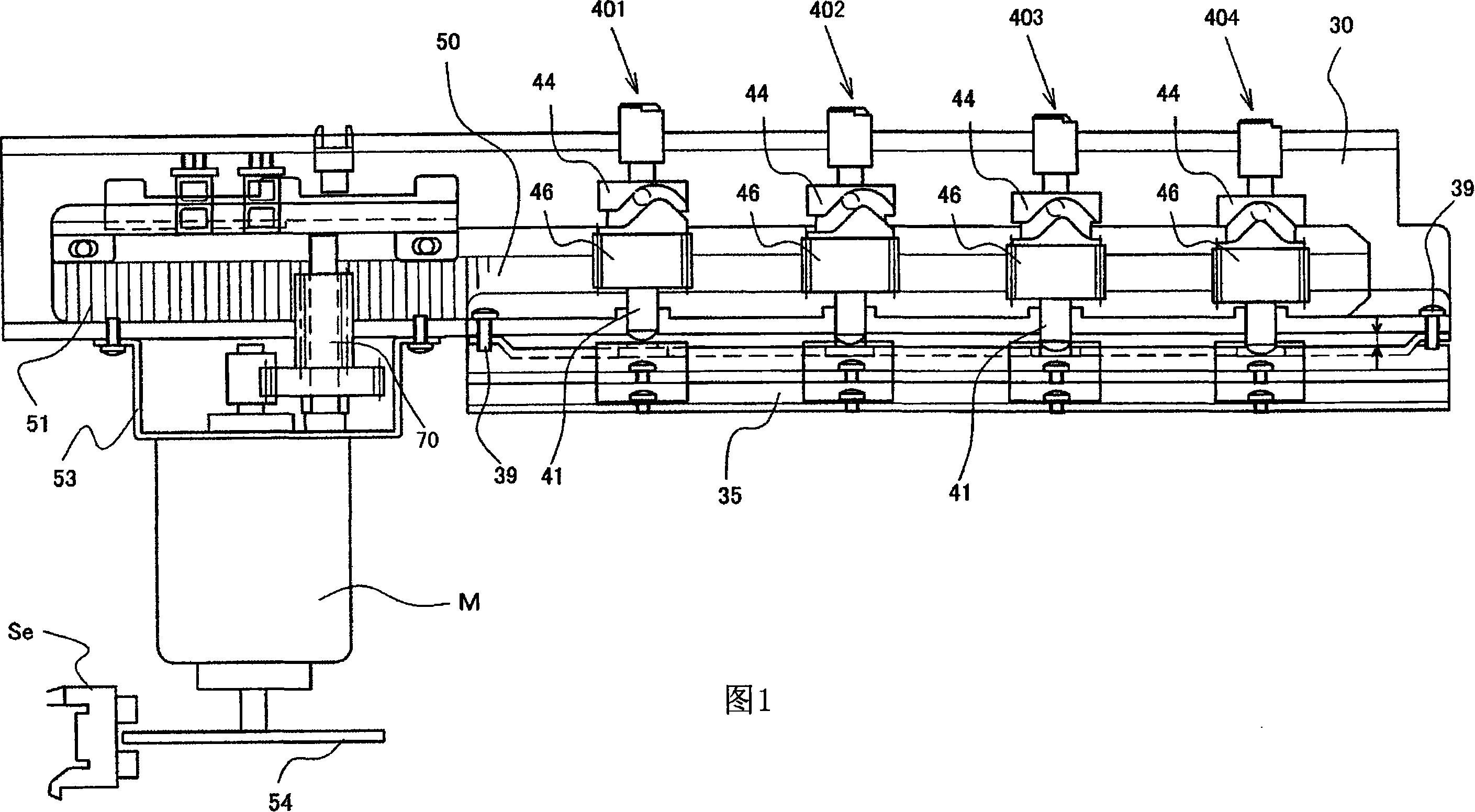

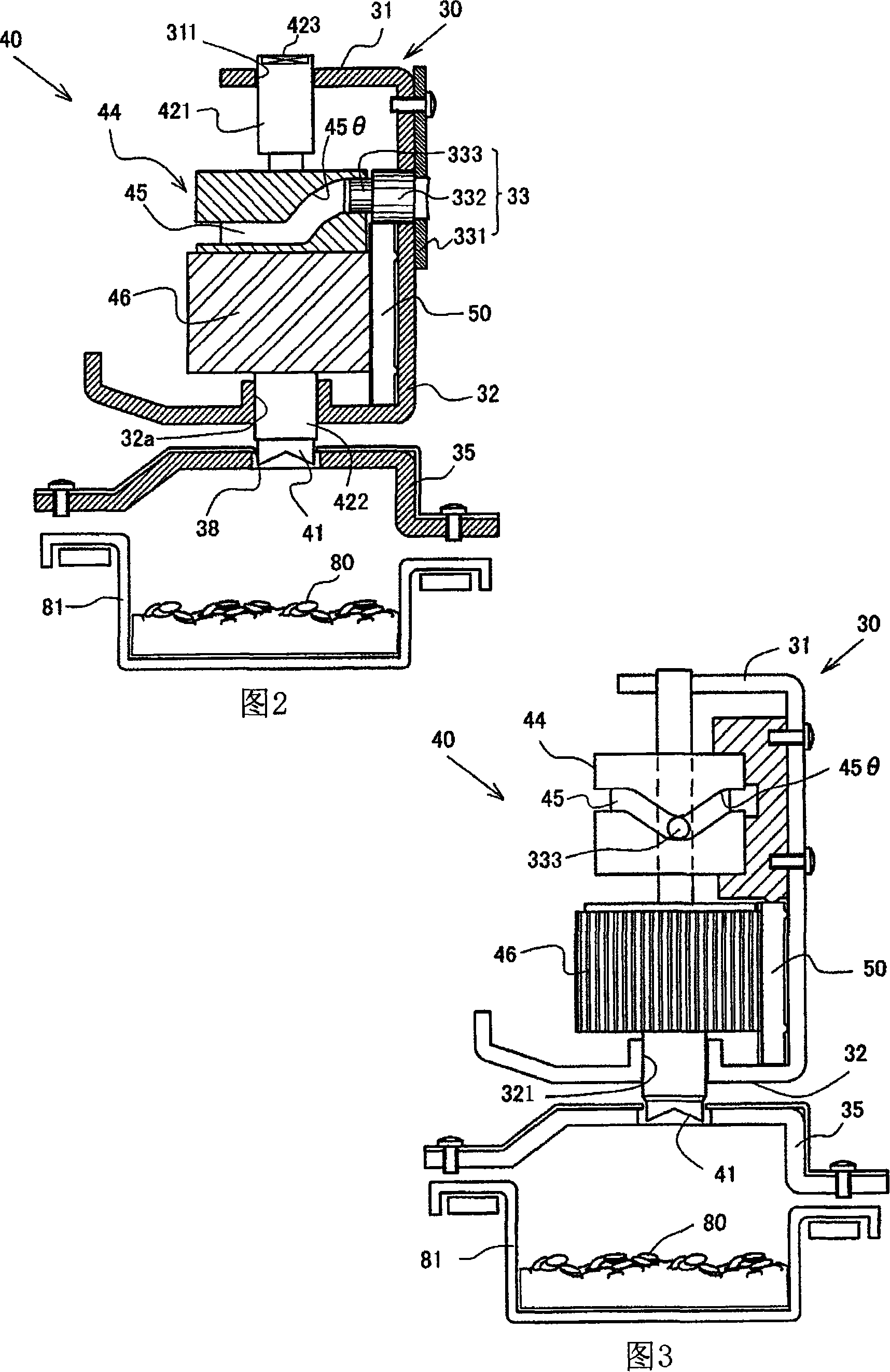

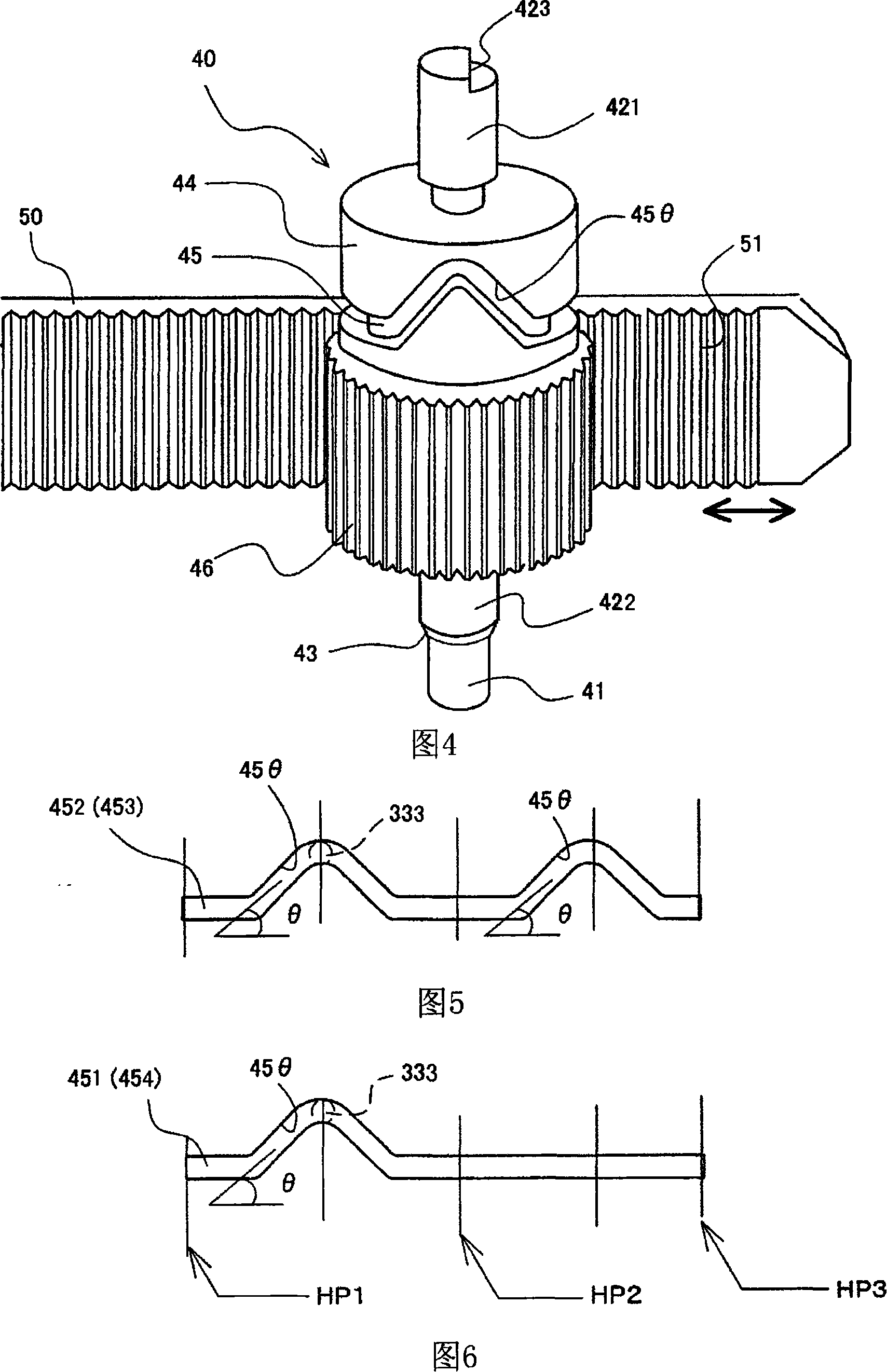

[0039] As shown in Figures 1 and 2, the perforating device of Embodiment 1 consists of an upper base 30 of a size corresponding to the perforated plate, a lower base 35 (also called an upper base 35) spaced between the upper base 30 and the perforated plate "Punching station"), the punching part 40 installed on the upper base 30 and the punching 38 arranged on the lower base 35, the driving motor M, the transmission mechanism and the cam mechanism are composed, and the above-mentioned punching part 40 is cylindrical , be provided with upper shaft 421 and lower shaft 422, and be provided with punching knife 41 at its front end namely lower end, punching part 40 is provided with 2 or 3 at intervals according to the specification (file hole specification) that upper abutment 30 decides Or 4 etc., the present embodiment is provided with 4: the first punching part 401 , the second punching part 402 , the third punching part 403 , the fourth punching part 404 .

[0040]The punching ...

Embodiment 2

[0065] Referring to Fig. 18 to Fig. 22, the second embodiment is described as follows.

[0066] The cylindrical cam 66 shown in FIGS. 18 and 19 is fixed on the upper base 30 , and a guide pin 65 combined with the cam groove 67 of the cylindrical cam 66 is provided on the side of the punching member 62 . In this embodiment, components having the same structure as those in Embodiment 1 are assigned the same numbers, and descriptions thereof are omitted.

[0067] The upper abutment 30 and the lower abutment 35 have the same composition as those in FIG. 1 , and both form a whole. The drive shaft 60 connected to the drive motor M is configured on the upper base 30. In addition, the same as the first embodiment, the upper base 30 is provided with an upper guide rail 31 and a lower guide rail 32, and its upper and lower guide holes 311, 321 It is automatically fitted up and down with the piercing member 40 . Four perforating members 40 are arranged, as shown in the figure, which is...

Embodiment 3

[0073] As shown in FIG. 23 , the difference between Embodiment 1 and Embodiment 2 in Embodiment 3 will be described below. The structure of the perforating member 62 is basically the same as that of the second embodiment, so the same numbers are used, and descriptions are omitted. The sliding cam 82 shown in FIG. 23 replaces the eccentric cam 61 in the second embodiment. The sliding cam 82 is connected with the driving motor, and a cam groove 83 with a V-shaped groove 831 is provided thereon. The cam groove 83 cooperates with the needle 832 on the top of the punching part 40, and the other structures of the punching part 62 are the same as those in the second embodiment.

[0074] As shown in Figure 23, when the sliding cam 82 is operated back and forth through a predetermined stroke, the pin 832 cooperating with the cam groove 83 moves from the upper apex of the V-shaped groove 831 to the lower apex, and moves to the thrust direction. The punching member 62 rotates along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com