Control method and device for fuel injection

A technology of fuel injection and control device, applied in the direction of fuel injection control, fuel injection device, electrical control, etc., can solve problems such as fuel injection correction, and achieve the effect of correct fuel injection control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

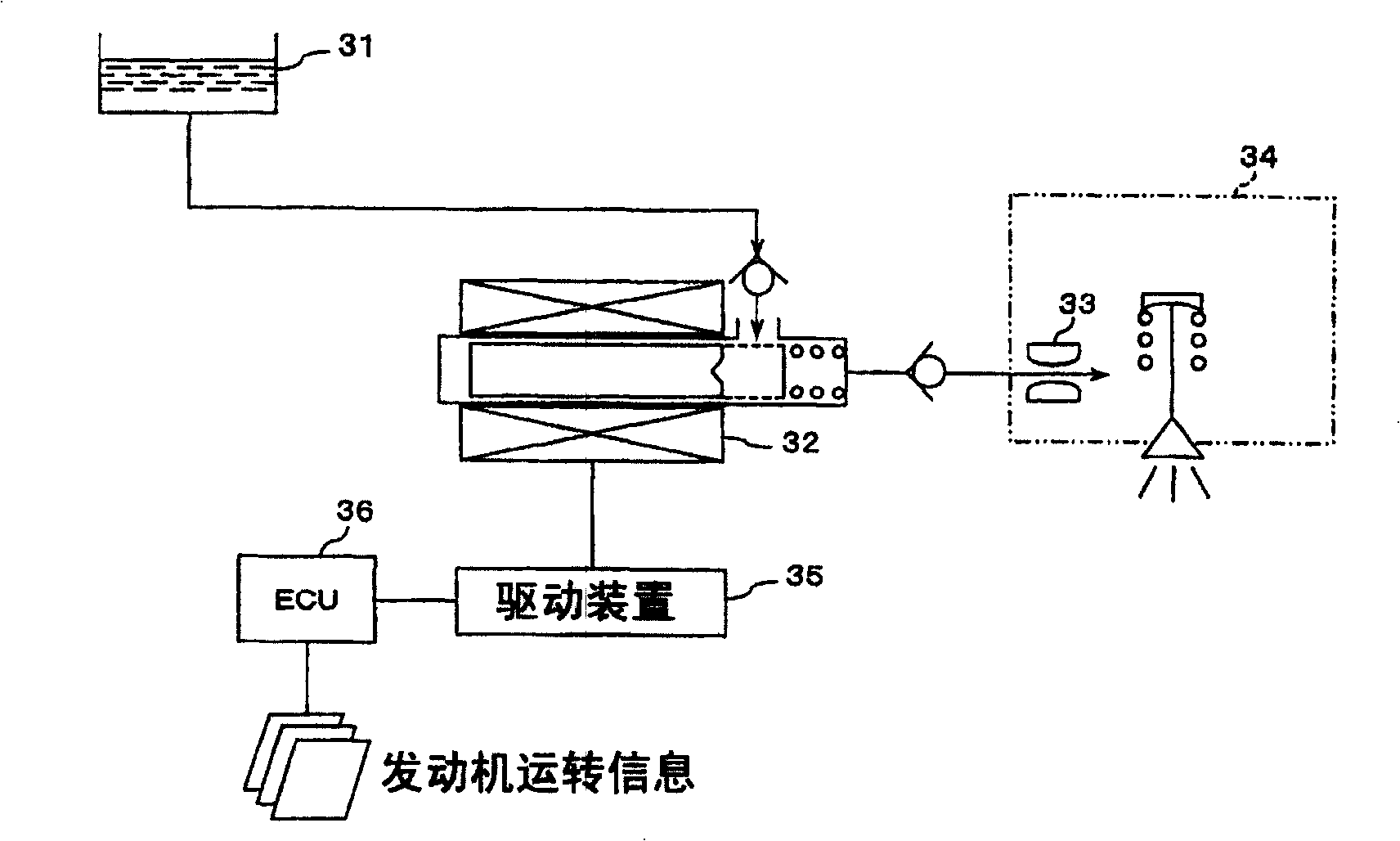

[0044] figure 1 An example of an overall schematic configuration of an electromagnetic fuel injection system including a fuel injection control device according to the present invention is shown.

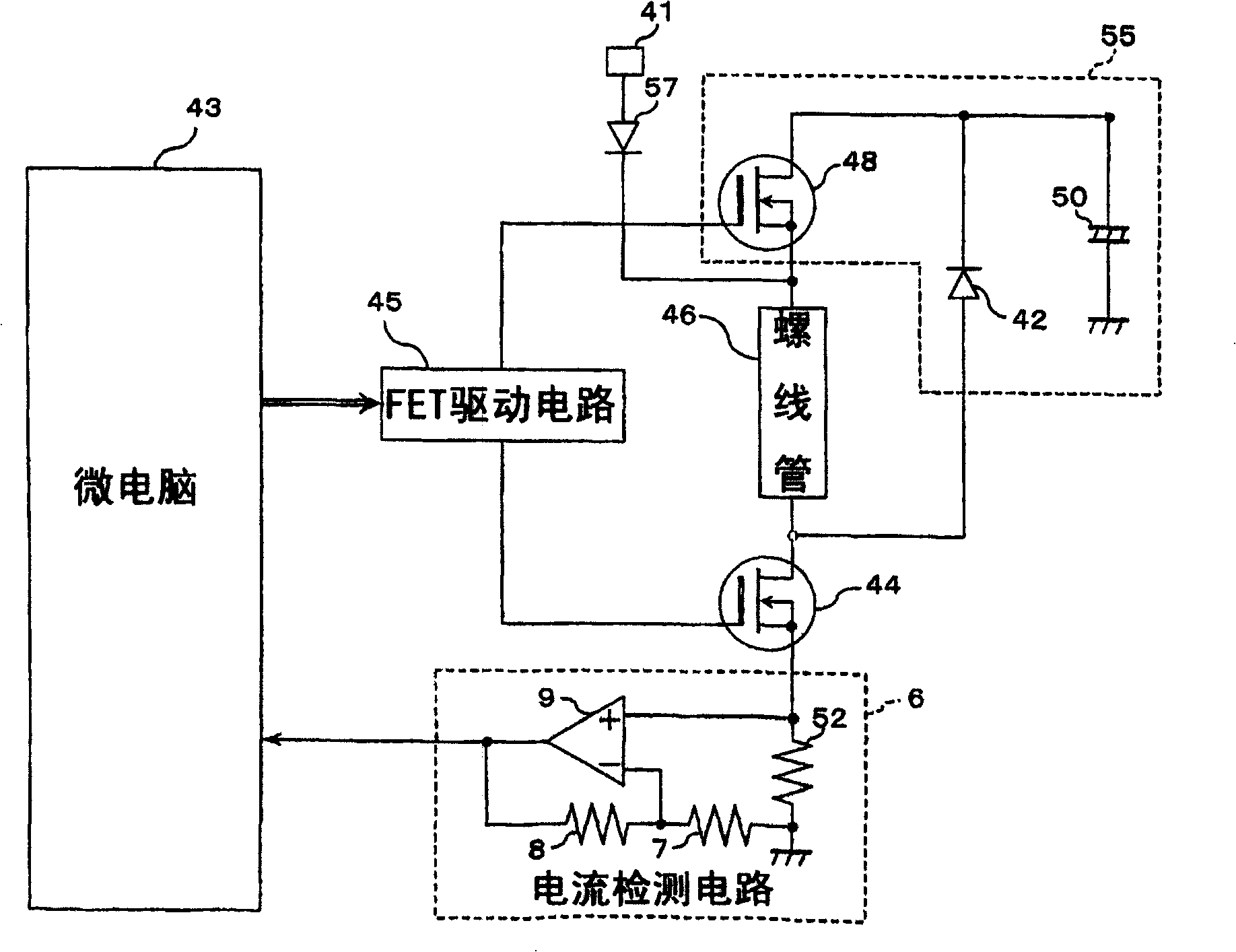

[0045] Such as figure 1 As shown, the basic structure of the electromagnetic fuel injection system includes: a plunger pump (plunger pump) 32 as an electromagnetically driven pump for pressure-feeding the fuel in the fuel tank 31; The inlet hole nozzle 33 of the orifice (orifice) portion of the fuel; the injection nozzle 34 that injects into the intake passage (of the engine) when the fuel passing through the inlet hole nozzle 33 is greater than a specified pressure; and the operating information of the engine and A control unit (ECU) 36 that outputs a control signal to the plunger pump 32 and the like based on a coil current flowing through a solenoid (fuel injection solenoid in this application) of the plunger pump 32 . Here, the control device in the fuel injection control de...

no. 2 Embodiment approach

[0065] Next, the fuel injection method according to the second embodiment of the present invention is applied to figure 1 The case of the electromagnetic fuel injection system of the structure shown is explained as an example. Since it overlaps with the previous example of the first embodiment, description of the configuration of the electromagnetic fuel injection system is omitted.

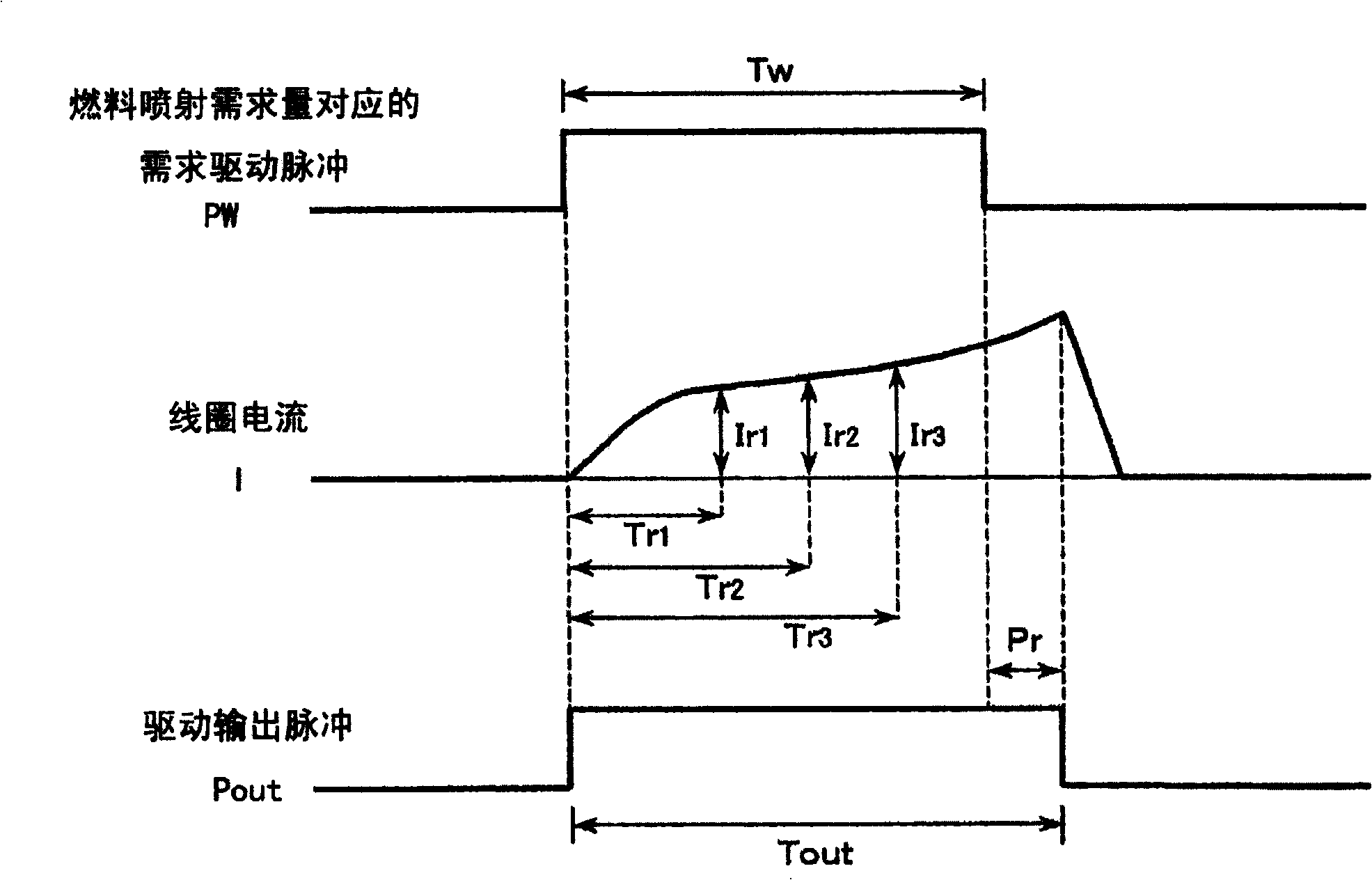

[0066] Here, in the present second embodiment, based on the slope correction value represented by the ratio of the increase amount of the fuel injection demand amount Qc to the increase amount of the solenoid drive output pulse width Tout, and the start of the solenoid drive to the start The corrected dead time between fuel injections is added to the product value of the required drive pulse corresponding to the fuel injection demand Qc and the slope correction value, and the corrected dead time is added to obtain the drive output pulse width Tout.

[0067] Figure 6 The relationship between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com