Dynamo-electric machine

A technology for rotating electrical machines and rotors, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as heating of stators and stator coils, lower operating efficiency, etc., achieve pressure loss suppression, high efficiency, and small and lightweight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the rotating electric machine according to the present invention will be described using the drawings.

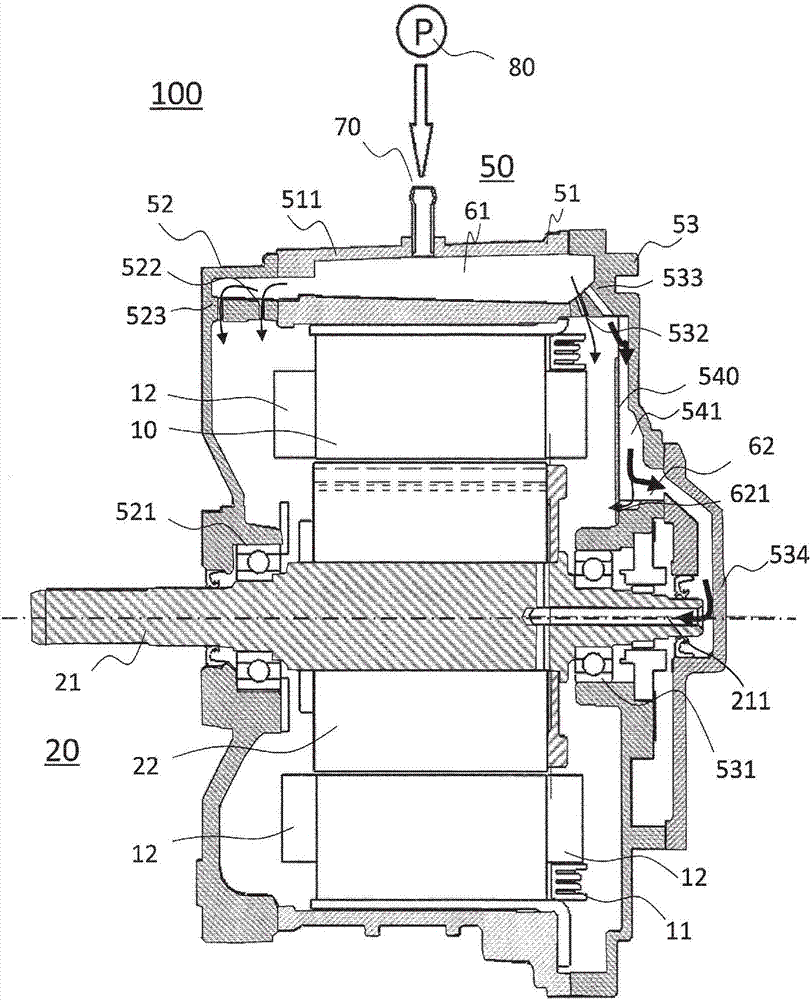

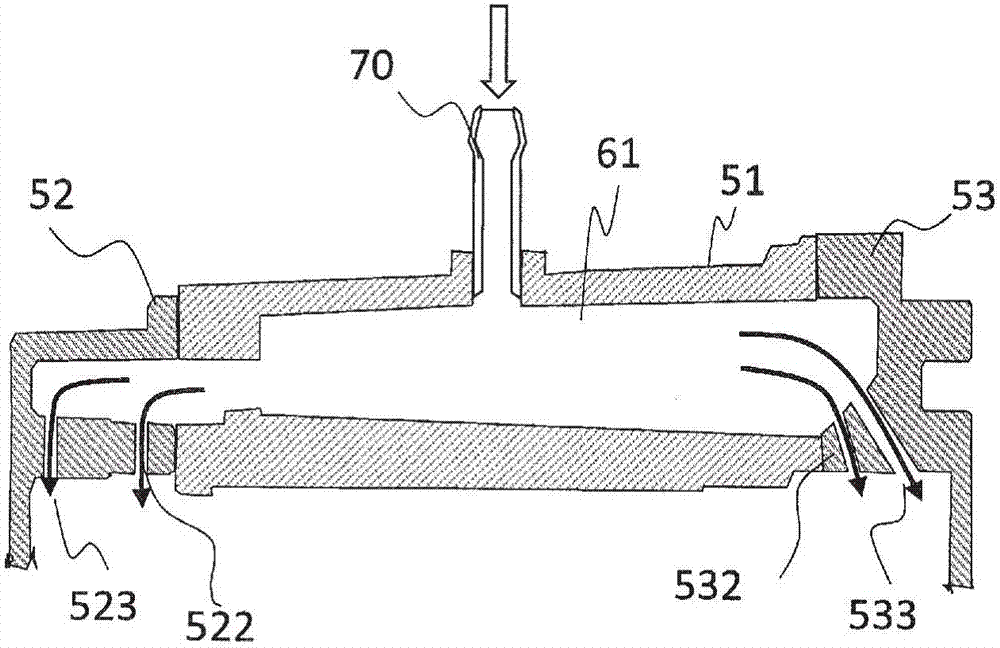

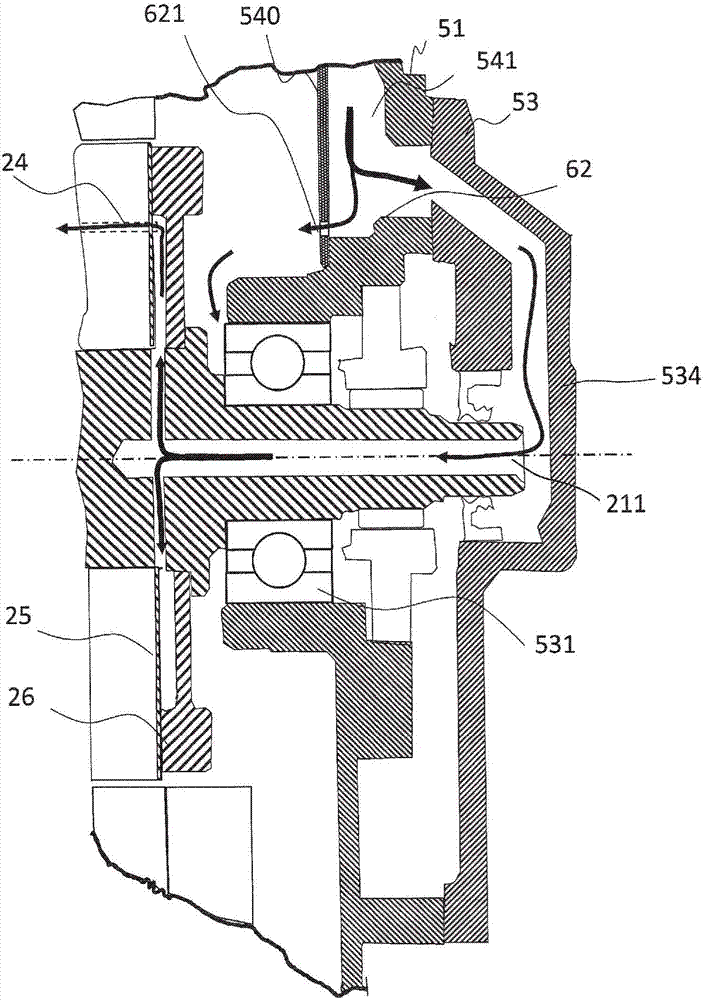

[0024] figure 1 It is a schematic cross-sectional view showing one embodiment of the rotating electric machine 100 of the present invention, that is, a cross-sectional view in the direction of the rotation axis of the rotating electric machine 100 .

[0025] The casing 50 of the rotating electrical machine 100 includes a middle frame 51 of the main body, a front frame 52 and a rear frame 53, and forms a structure in which both ends of the above-mentioned middle frame 51 are closed by the front frame 52 and the rear frame 53, and the stator 10 is fixed in the middle of the above-mentioned casing 50 The frame 51 and the rotating shaft 21 of the rotor 20 are supported by the front frame 52 and the rear frame 53 via bearings 521 and 531, respectively. In addition, the stator 10 has a divided cylindrical shape arranged in an annular shape, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com