Battery pack

A battery and package technology, applied in the direction of batteries, electric power devices, battery pack components, etc., can solve the problems of higher position, loading, and increased thickness of the fuel cell system box in the upper and lower directions, and achieve small size in the height direction, Achieve lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0037] Below, based on Figure 1 to Figure 5 The first embodiment of the present invention will be described.

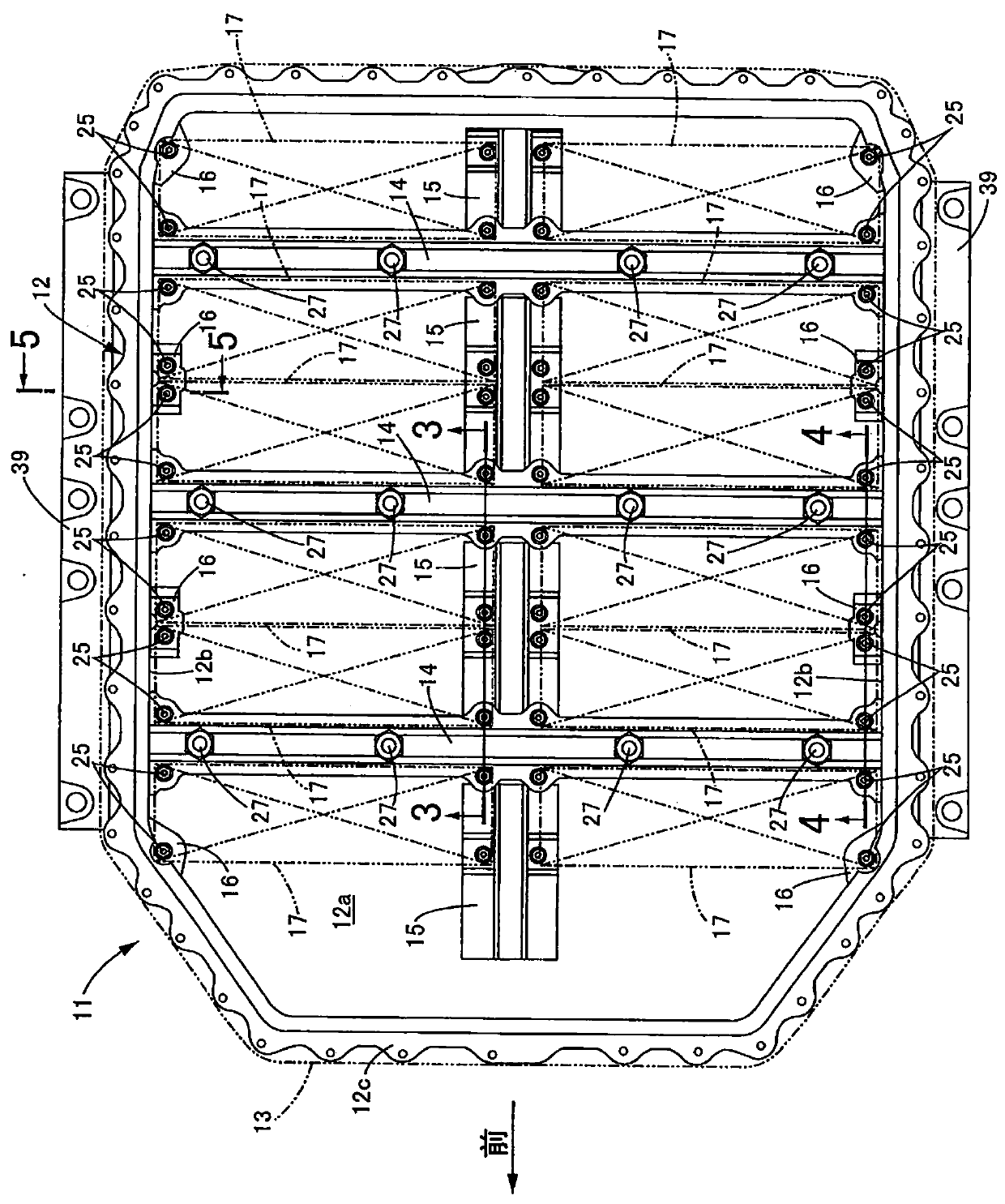

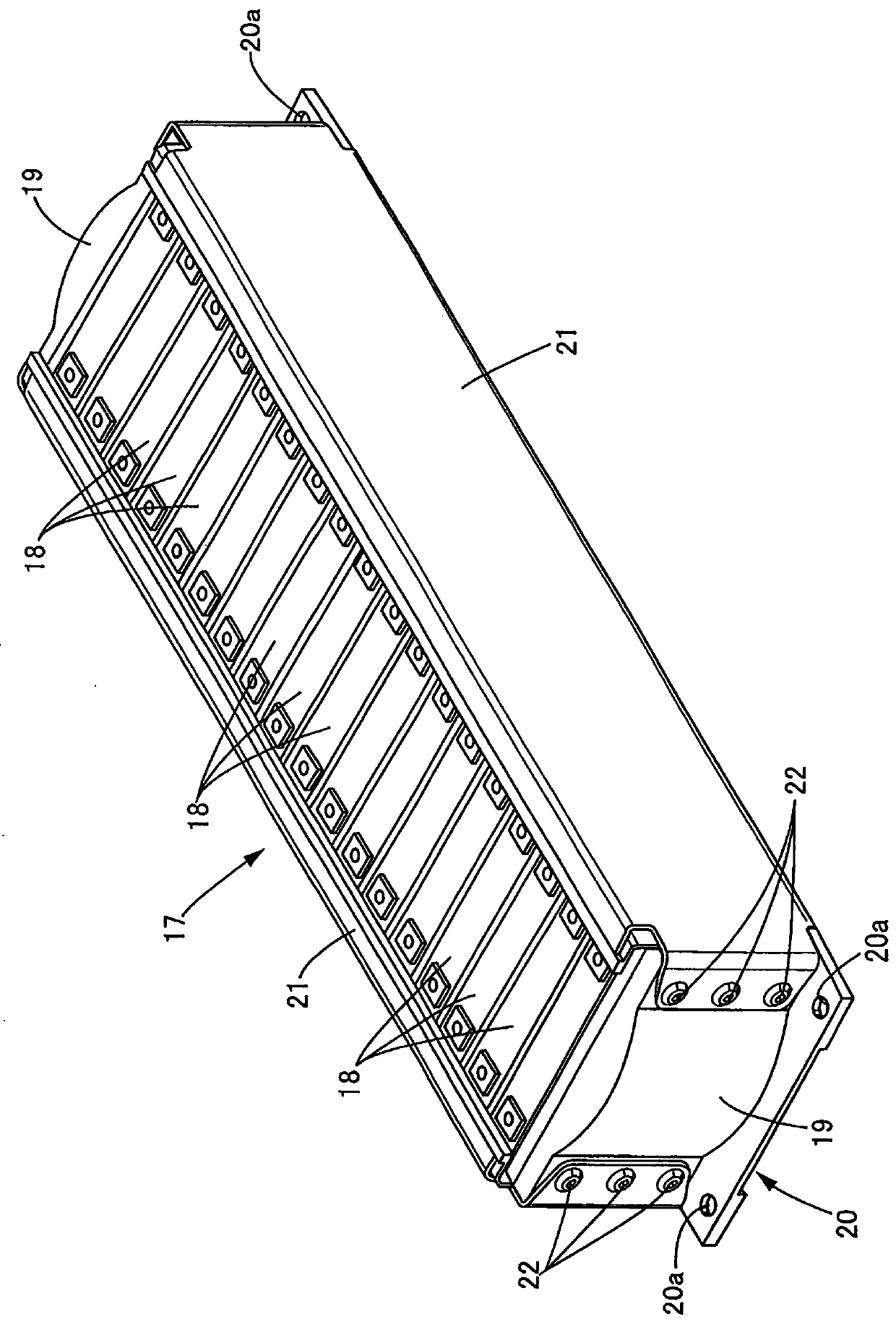

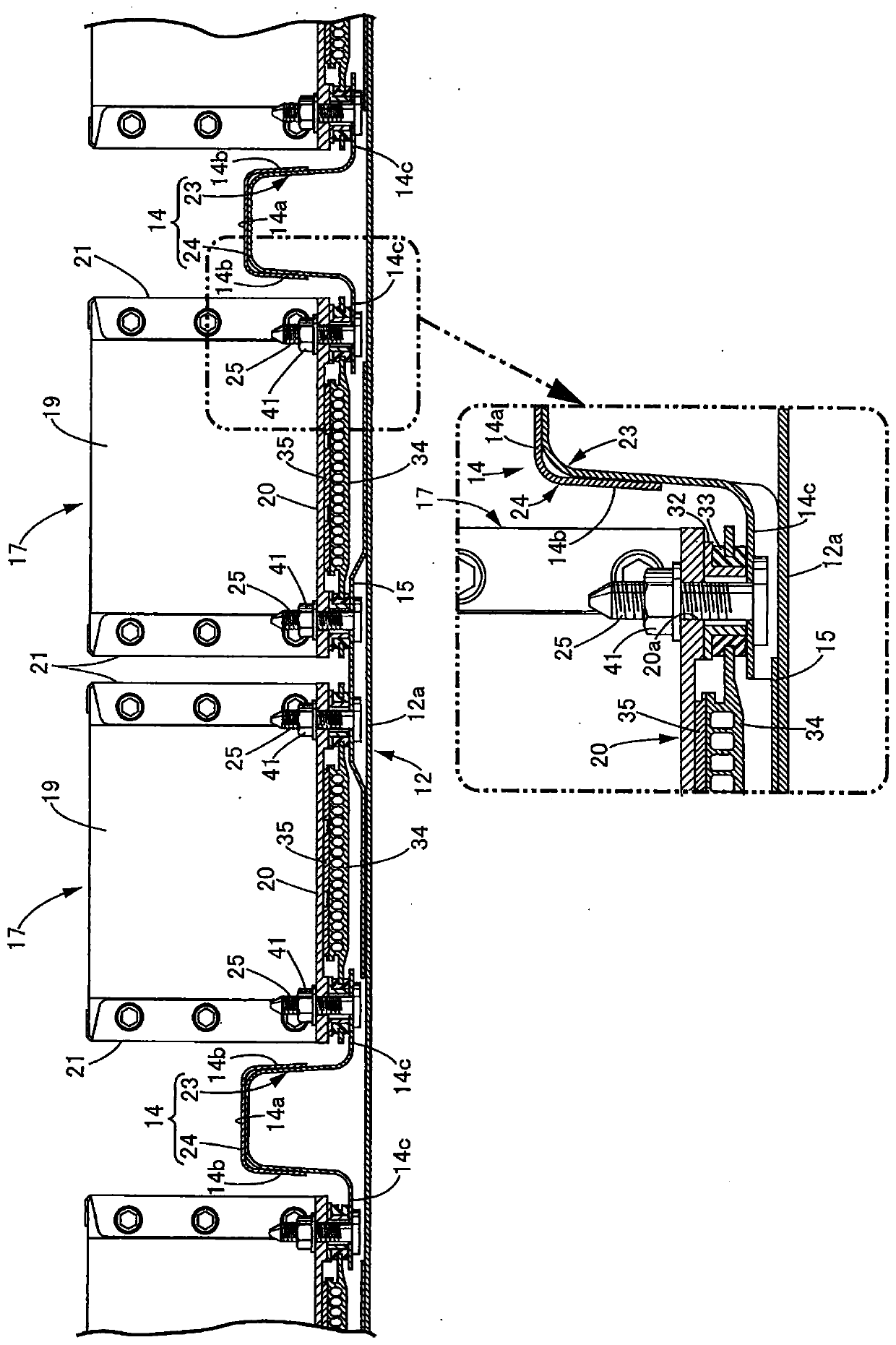

[0038] Such as figure 1 As shown, a battery pack 11 installed under the floor of an electric vehicle includes a container-shaped case 12 whose upper surface is open, and a cover 13 that closes the upper surface opening of the case 12 . On the bottom wall 12a of the casing 12, three cross beams 14... are provided at predetermined intervals in the front-rear direction and extend along the vehicle width direction, and are arranged on the center line of the casing 12 so as to be perpendicular to the three cross beams 14... The vertical frame 15 ... extended along the front-back direction is provided in the manner. The vertical frame 15... is divided into four parts at the position which intersects with three beams 14.... In addition, four support brackets 16 . In addition, 12 rectangular parallelepiped battery modules 17... are supported on the upper surfaces of the ...

no. 2 approach

[0054] Next, based on Figure 6 A second embodiment of the present invention will be described.

[0055] In the first embodiment, when the battery modules 17 ... are mounted on the case 12 of the battery pack 11, the direction in which the cells are stacked is along the vehicle width direction. However, in the second embodiment, the direction in which the cells are stacked is along the forward and backward direction. That is, the two front bolt holes 20a, 20a of each battery module 17 are supported by the flange 14c of the front beam 14, and the two rear bolt holes 20a, 20a are supported by the flange 14c of the rear beam 14. . Therefore, according to this embodiment, the stud bolts 25... of the support bracket 16... and the stud bolts 25... of the vertical frame 15 of 1st Embodiment are unnecessary.

[0056] According to this embodiment as well, it is possible to achieve the same effect as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com