Cylinder jacket and crosshead-type internal combustion engine

A crosshead type, cylinder cover technology, applied in the direction of cylinders, cylinder heads, mechanical equipment, etc., to achieve the effect of shortened length and high fastening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, preferred embodiments of the cylinder head and the crosshead internal combustion engine according to the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited by this embodiment, Moreover, when there are several embodiment, the form which combined each embodiment is also included.

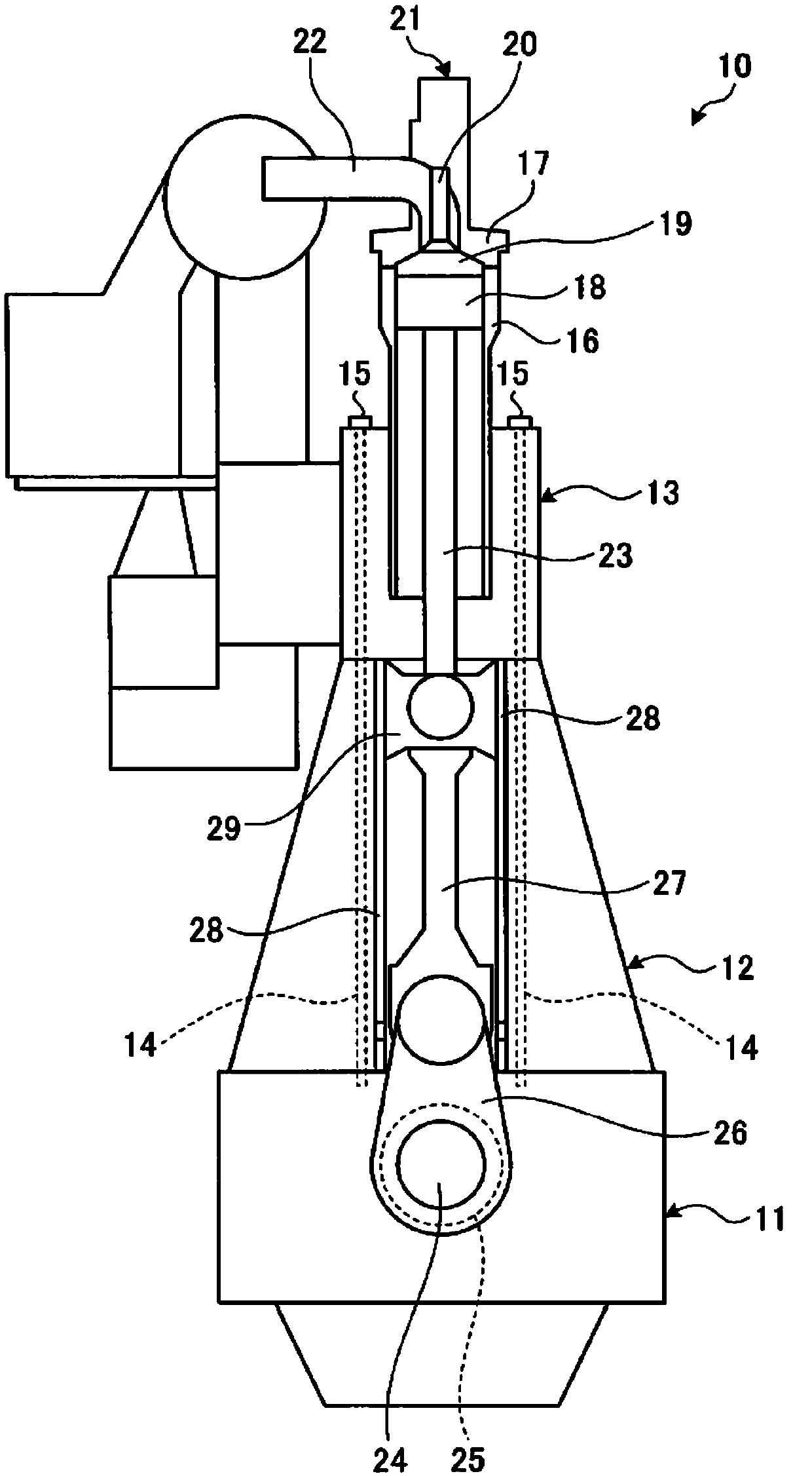

[0034] figure 1 It is a schematic diagram showing the diesel engine of this embodiment.

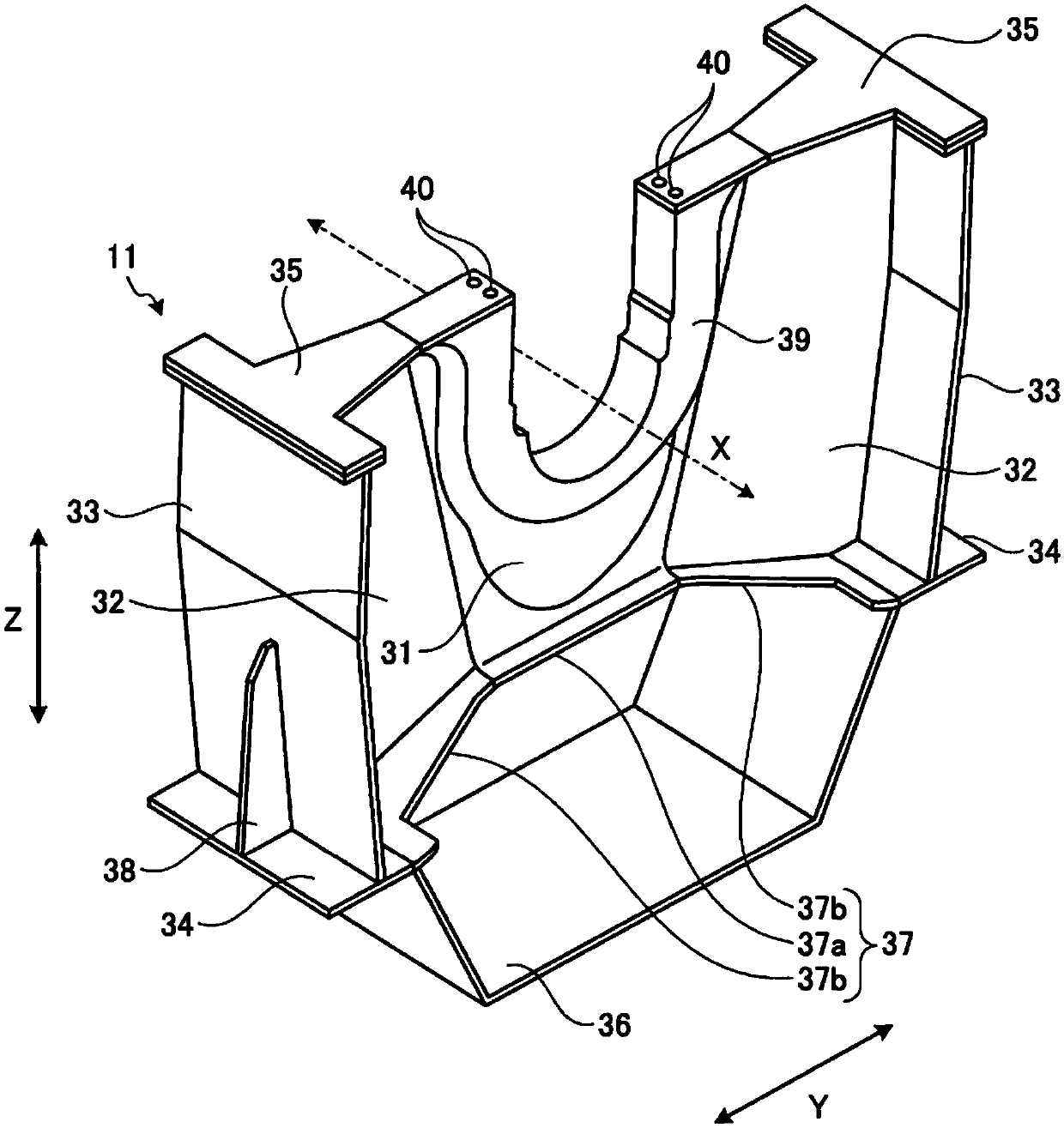

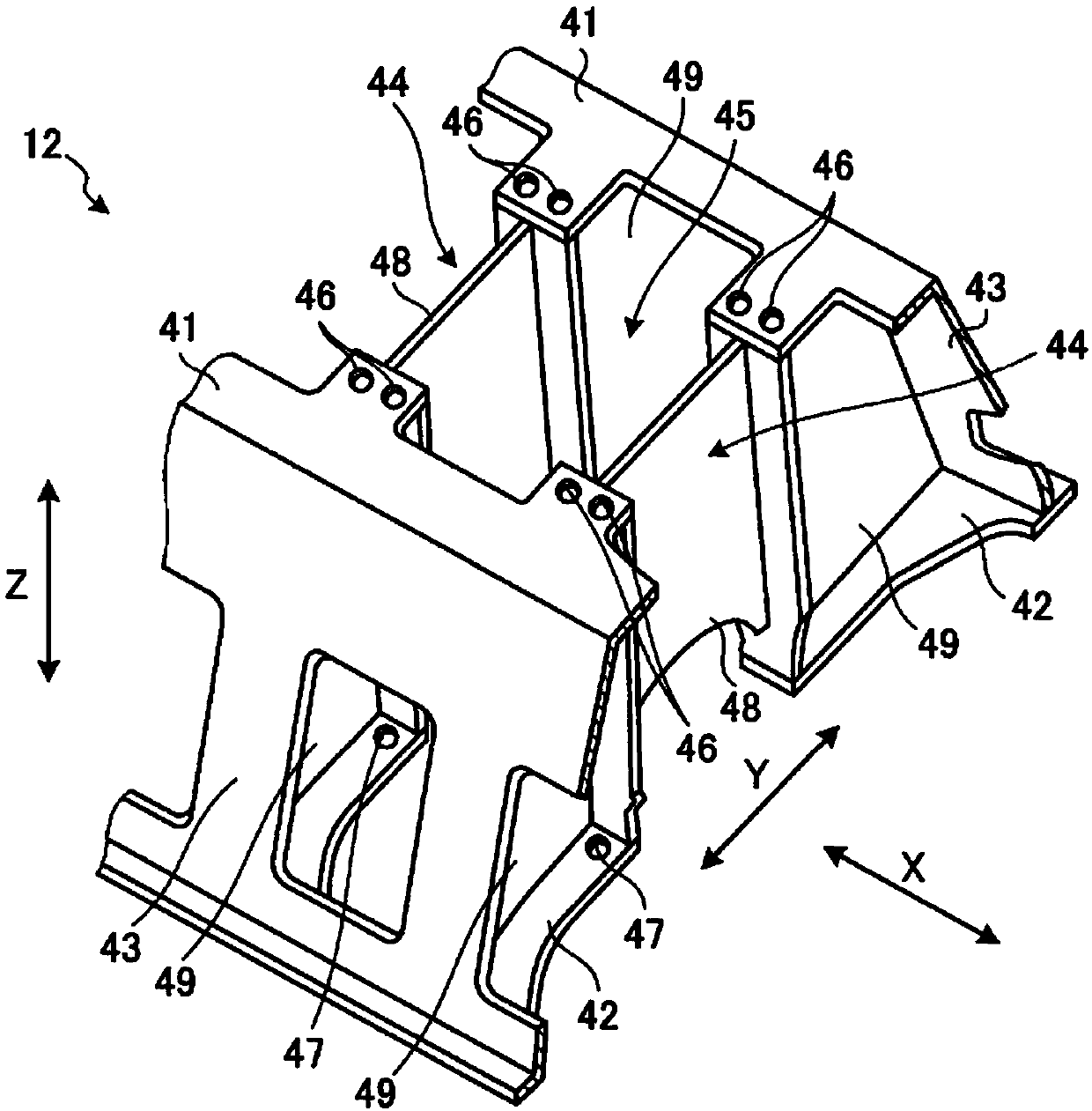

[0035] In this embodiment, if figure 1 As shown, the diesel engine 10 is, for example, a two-stroke, one-cycle single-flow scavenging type crosshead internal combustion engine used as a main engine for propulsion of a ship. The diesel engine 10 includes: a platform 11 located below; a frame 12 arranged on the platform 11 ; and a cylinder cover 13 arranged on the frame 12 . The platen 11 , the frame 12 and the cylinder cover 13 are integrally fastened and fixed by a plurality of tie bolts (coupling members) 14 and nuts 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com