Disk-type brake

A technology of disc brakes and brake pads, applied in the direction of brake types, axial brakes, brake components, etc., can solve the problem of unstable posture of brake pads, increase of piston arrangement distance, triangle defect of torque receiving part, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

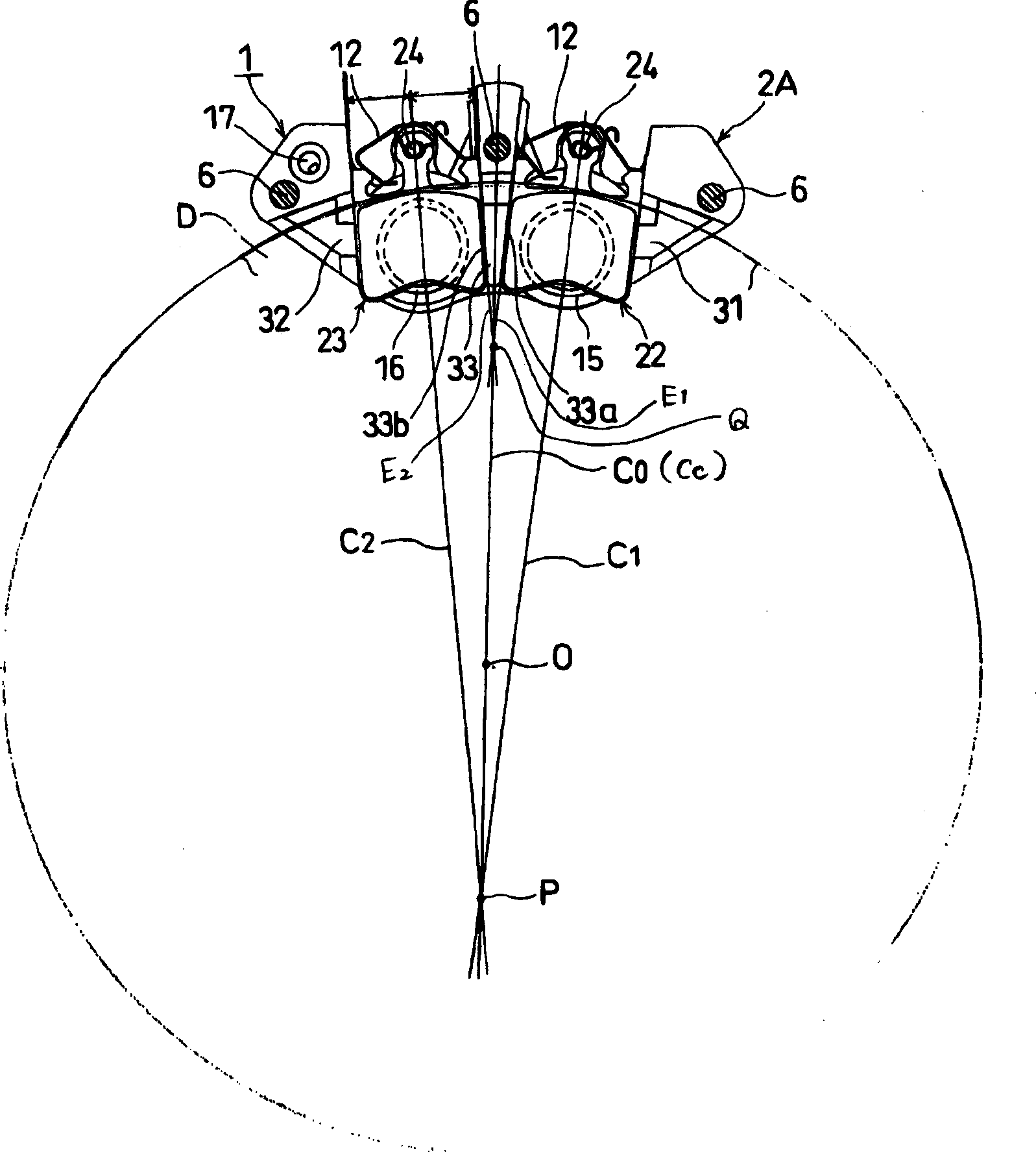

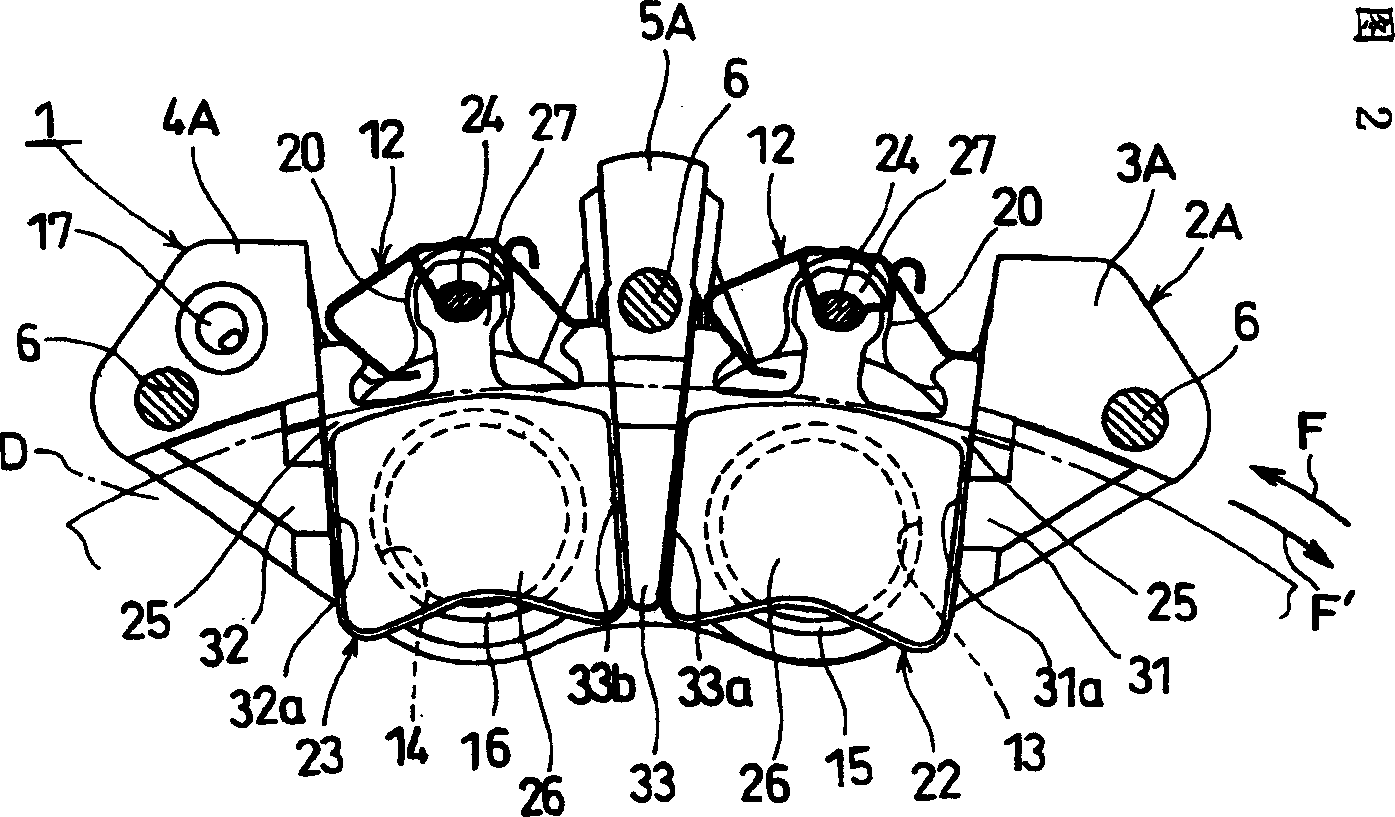

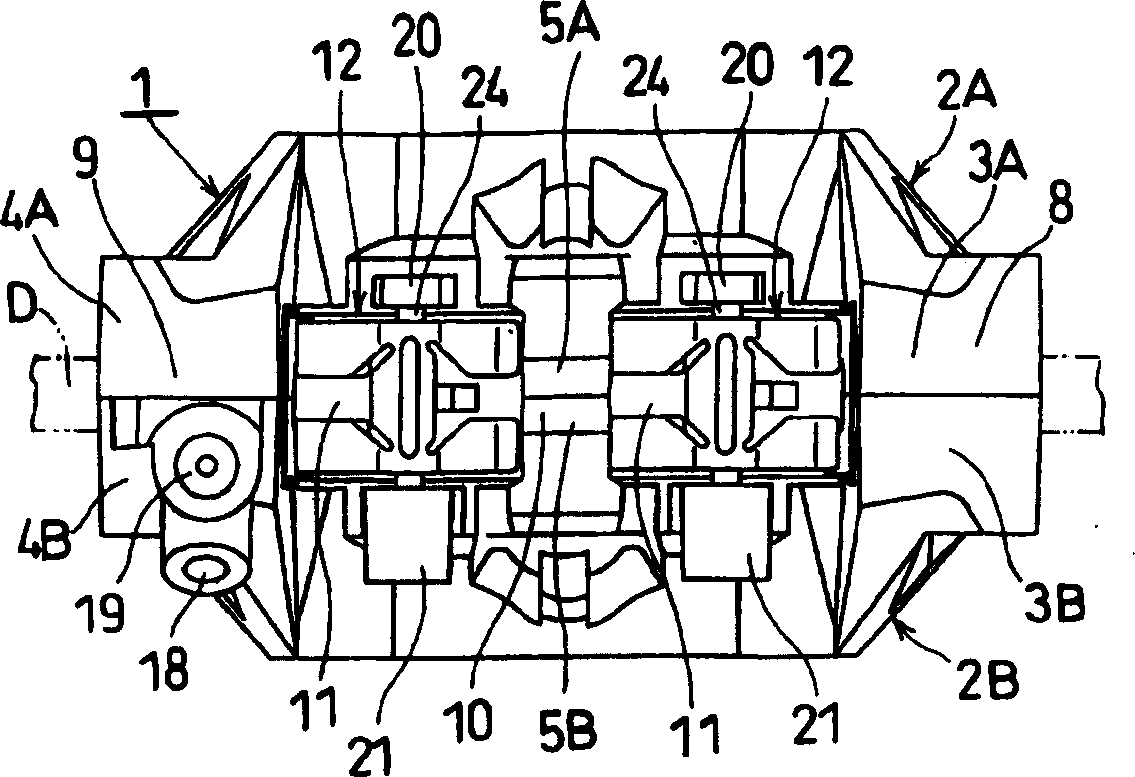

[0022] Embodiments of the present invention will be described below with reference to the drawings.

[0023] Figure 1 to Figure 7 Example 1 of the present invention is shown. As the disc brake of this embodiment 1, it is a fixed support frame, and its overall structure is shown in Figure 2- Figure 4 shown. In these figures, reference numeral 1 is a holder main body, and the holder main body 1 comprises an inner side holder half body 2A arranged inside the disk swivel D (vehicle inside) and a half body 2A arranged outside the disk turn D (vehicle outside). The outer support frame half body 2B is butted and connected as a whole. More specifically, each holder half body 2A and 2B has protrusions 3A, 4A protruding in the axial direction of the disc rotor D at three positions on both sides and the center along the circumferential direction of the disc rotor D. , 5A and 3B, 4B, 5B, in the state where these opposite protrusions 3A and 3B, 4A and 4B, 5A and 5B are butted against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com