3d shape testing device

A technology for measuring device and three-dimensional shape, applied in the field of devices, can solve problems such as inability to measure inclination and eccentricity, deterioration of Z-axis movement straightness, inability to measure the surface and back, and achieve the effects of light probe, reduced measurement error, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

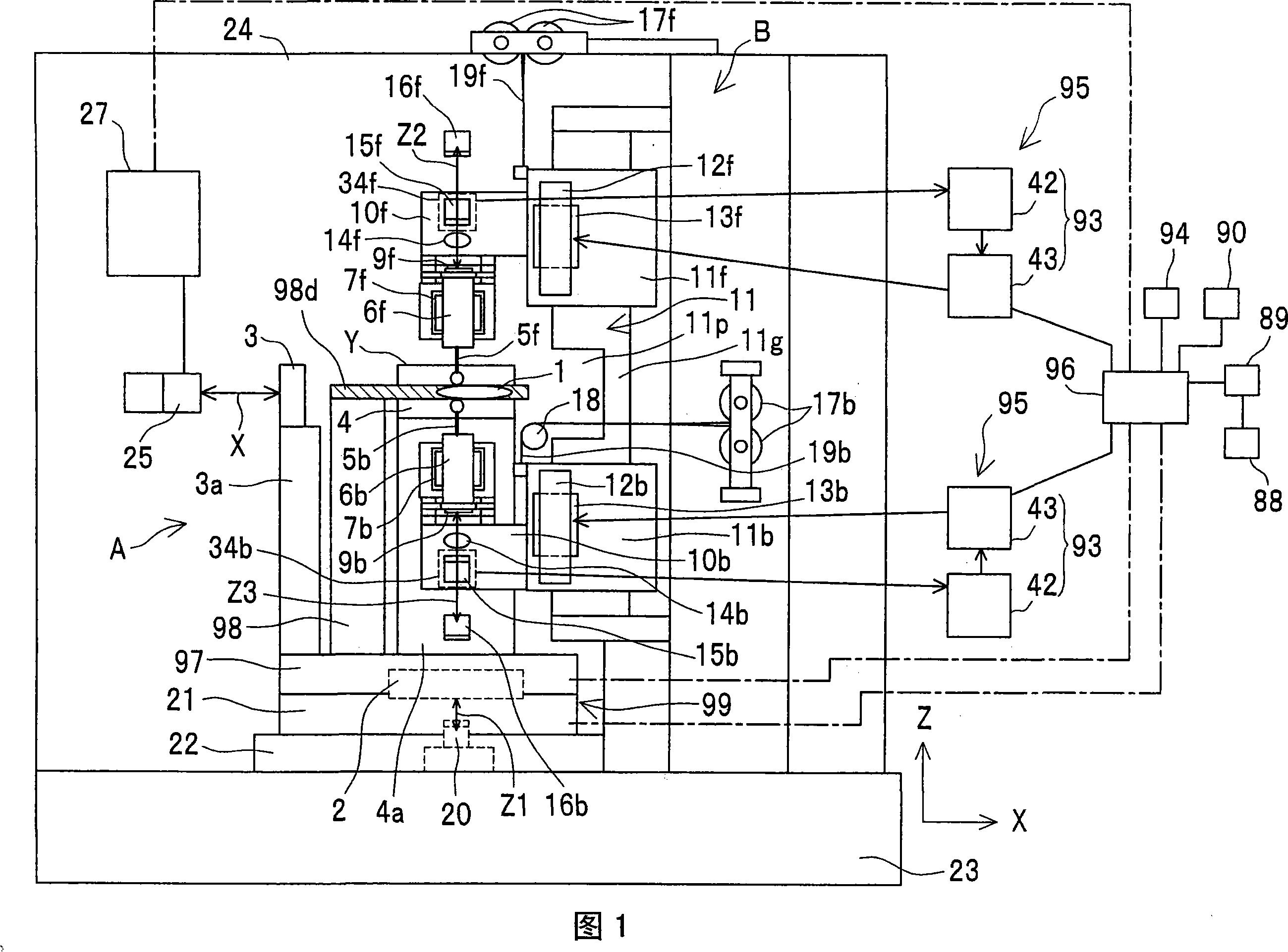

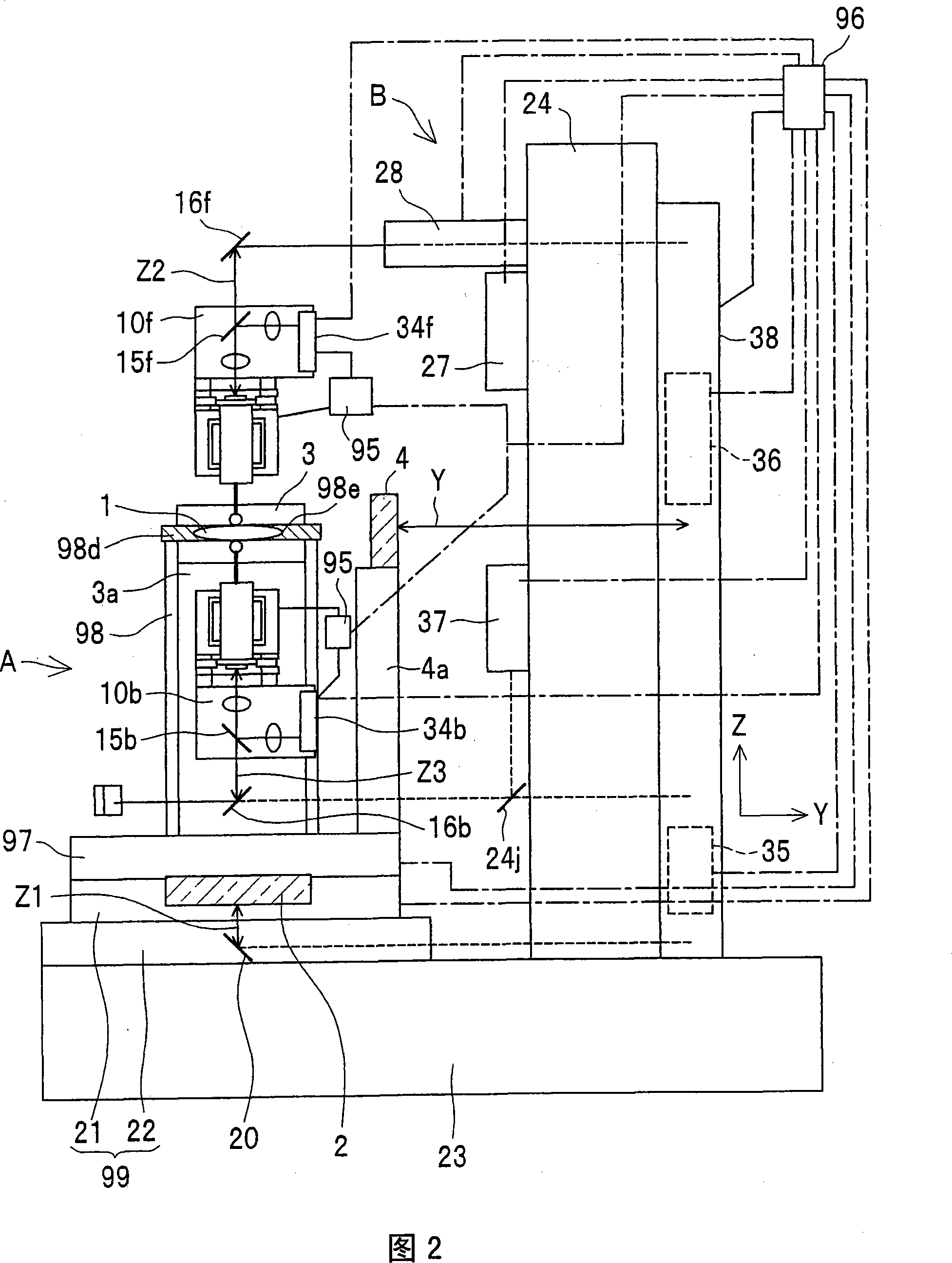

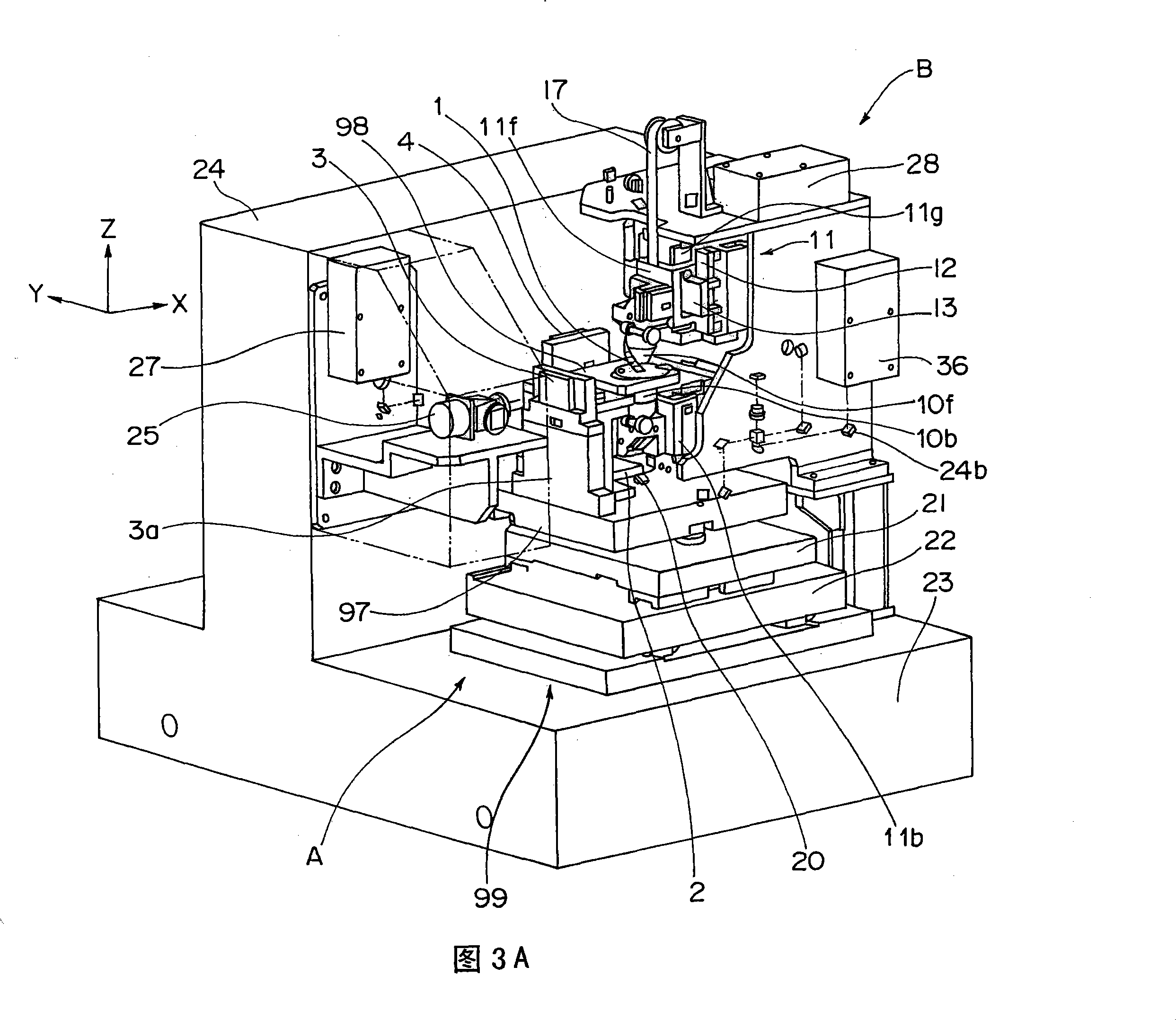

[0141] Fig. 1 is a front view showing the structure of a three-dimensional shape measuring device in the first embodiment of the present invention, Fig. 2 is a right sectional side view viewed from the right side after being cut from the center of Fig. 1 , and Fig. 3A and Fig. 3B are Stereoscopic view and its partial enlargement.

[0142] The three-dimensional shape measuring device is configured to include: a lower stone platform 23; a side stone platform 24, which is erected and fixed on the back side of the upper surface of the lower stone platform 23; a first unit A, which has measurement object holding members 98, Z Reference mirror (Z direction reference mirror, hereinafter referred to as "Z reference mirror") 2, X reference mirror (X direction reference mirror, hereinafter referred to as "X reference mirror") 3 and Y reference mirror (Y direction reference mirror, hereinafter referred to as "Y Reference mirror ") 4; second unit B, which has at least Zf mirror part 9f, Z...

no. 2 approach

[0198] In the first embodiment, the structure itself of the large air bearing 11 has been particularly described in detail, however, in the three-dimensional shape measuring device according to the second embodiment of the present invention, the two measuring probes 10f are moved in the Z direction The guide portion along the Z direction of the measuring probe moving device 93 in 10b, that is, the guide rail portion 11g of the large air bearing 11 is constituted by the same processing plane up and down. Specifically, as shown in FIG. 1 , the guide rail portion 11g of the large air bearing 11 is cut off at the left side of the central portion (refer to 11p) in order to prevent mutual interference with the measuring object 1, and the right side of the guide rail portion 11g and the paper The planes parallel to each other are connected up and down to form one. In addition, since the guide rail portion 11g of the large air bearing 11 is a square prism, it has four faces, and these...

no. 3 approach

[0201] In the first and second embodiments, it was described that the directions of the coordinate axes of the front and back of the measurement object 1 can be completely aligned. However, it is actually extremely difficult to align the stylus 5f and 5b on the same Z-axis with an accuracy of less than 0.1 micron.

[0202] Therefore, in the three-dimensional shape measuring device according to the third embodiment of the present invention, as shown in FIGS. 4A and 3D , the reference ball 91 having a good sphericity is supported on the part of the measuring object holding plate portion 98d of the measuring object holding member 98. The through hole 98e measures the supported reference ball 91 from the surface (upper surface or front surface) and back surface (lower surface or rear surface) of the supported reference ball 91 by the stylus 5 and 5b. As the reference ball 91, those with a degree of sphericity of 30 nm can be relatively easily manufactured. In addition, in the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com