High-throughput device and preparation analysis method for rapid analysis of wetting-reaction behavior of ternary liquid alloy matrix and reinforcement

A liquid alloy, rapid analysis technology, applied in the direction of measuring devices, analysis materials, permeability/surface area analysis, etc., can solve the problem of inability to quickly and effectively analyze the wetting behavior of ternary liquid alloy matrix and reinforcement, and achieve precise control Impregnation time, strong mutual contrast, and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

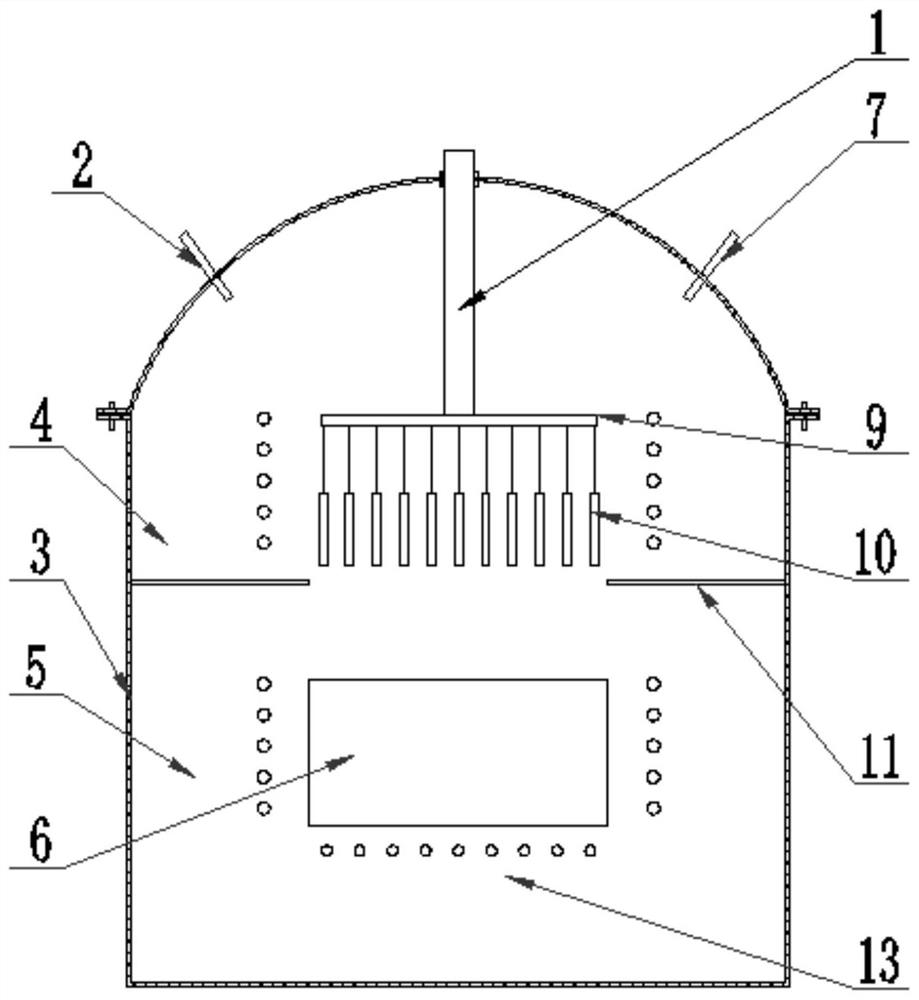

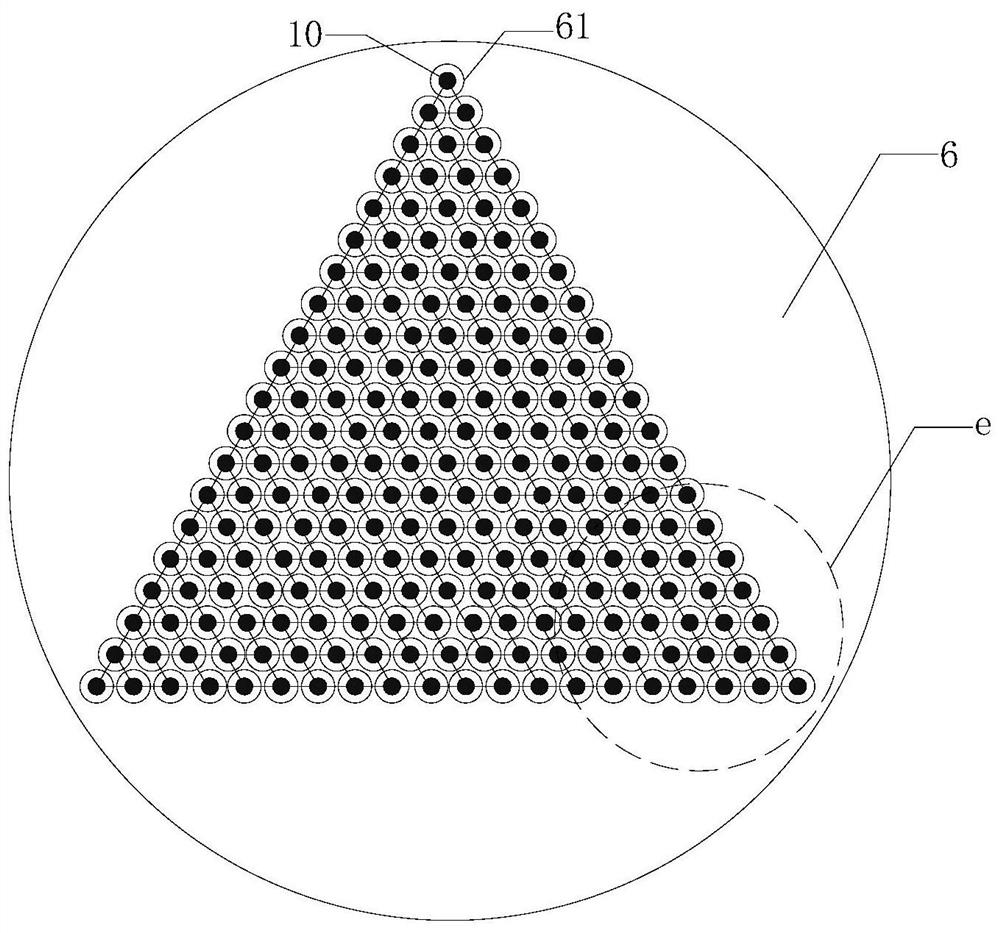

[0041] Specific Embodiment 1: In this embodiment, the high-throughput device for quickly analyzing the wetting-reaction behavior of the ternary liquid alloy matrix and reinforcement consists of a lifting rod 1, an exhaust pipe 2, a furnace body 3, a preheating zone 4, a melting zone 5, A crucible 6, an air-filled tube 7, a prefabricated body mounting plate 9, a plurality of prefabricated bodies 10, a heat shield 11 and a crucible heating zone 13;

[0042] The furnace body 3 is a sealed hollow body, and the inner middle of the furnace body 3 is provided with a horizontal annular heat insulating plate 11, which is fixedly connected to the inner wall of the furnace body 3, and the upper part of the inner annular heat insulating plate 11 of the furnace body 3 It is the preheating zone 4, the lower part of the annular heat shield 11 in the furnace body 3 is the smelting zone 5, and the bottom of the smelting zone 5 is the crucible heating zone 13, in the preheating zone 4 near the i...

specific Embodiment approach 2

[0049] Embodiment 2: This embodiment differs from Embodiment 1 in that: the number of crucible chambers 61 is 28-1035. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0050] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the adhesive is polyvinyl alcohol. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com