Cathode material for sodium-ion battery, preparation method of cathode material and sodium-ion battery

A sodium-ion battery and positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limiting the production of graphene and sodium-ion battery materials, unfavorable mass production, etc., to improve electrochemical performance and realize freedom The effect of transforming and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a method for preparing a positive electrode material for a sodium ion battery, comprising the following steps:

[0039] A) mixing and ball milling the sodium source compound, the vanadium source compound and the phosphorus source compound with a solvent to obtain a mixed solution;

[0040] B) drying the mixed solution to obtain a precursor;

[0041] C) pre-calcining the precursor under an inert atmosphere to obtain calcined powder;

[0042] D) mixing the calcined powder with the second carbon source compound, and sintering in an inert atmosphere to obtain a positive electrode material for a sodium ion battery.

[0043] In the invention, the sodium source compound, the vanadium source compound and the phosphorus source compound are mixed and ball-milled with a solvent to obtain a mixed solution.

[0044] Specifically, in the present invention, after mixing the sodium source compound, the vanadium source compound and the phosphorus source compound...

Embodiment 1

[0067] Mix 0.09mol sodium acetate, 0.09mol ammonium dihydrogen phosphate, and 0.06mol ammonium metavanadate, add 15wt% citric acid, put in a ball mill jar and add acetone ball mill for 12 hours to make it evenly mixed, and put the evenly mixed solution into Dry in an oven at 80°C to obtain a precursor; place the precursor in an argon-hydrogen atmosphere for pre-sintering, the pre-sintering temperature is 400°C, and the pre-sintering time is 6 hours to obtain a calcined powder; take 1g of the calcined powder and 15wt% The polyvinyl alcohol is mixed and ground evenly, placed in an argon-hydrogen atmosphere for the second step of sintering, the sintering temperature is 750°C, and the sintering time is 12 hours to obtain the finished powder.

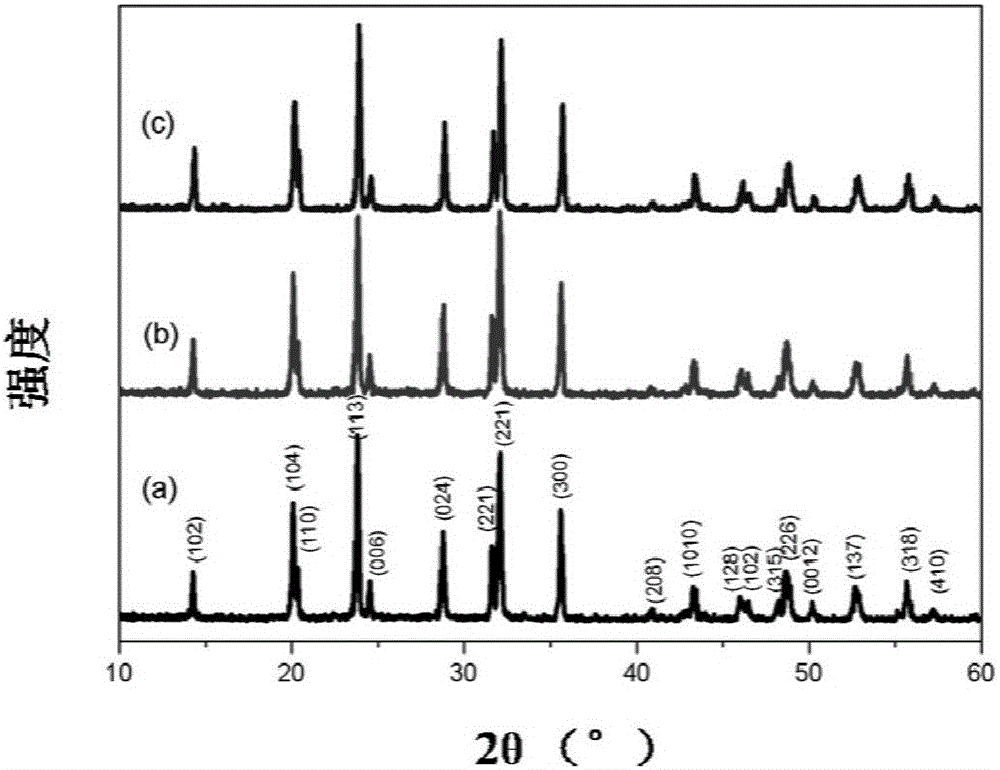

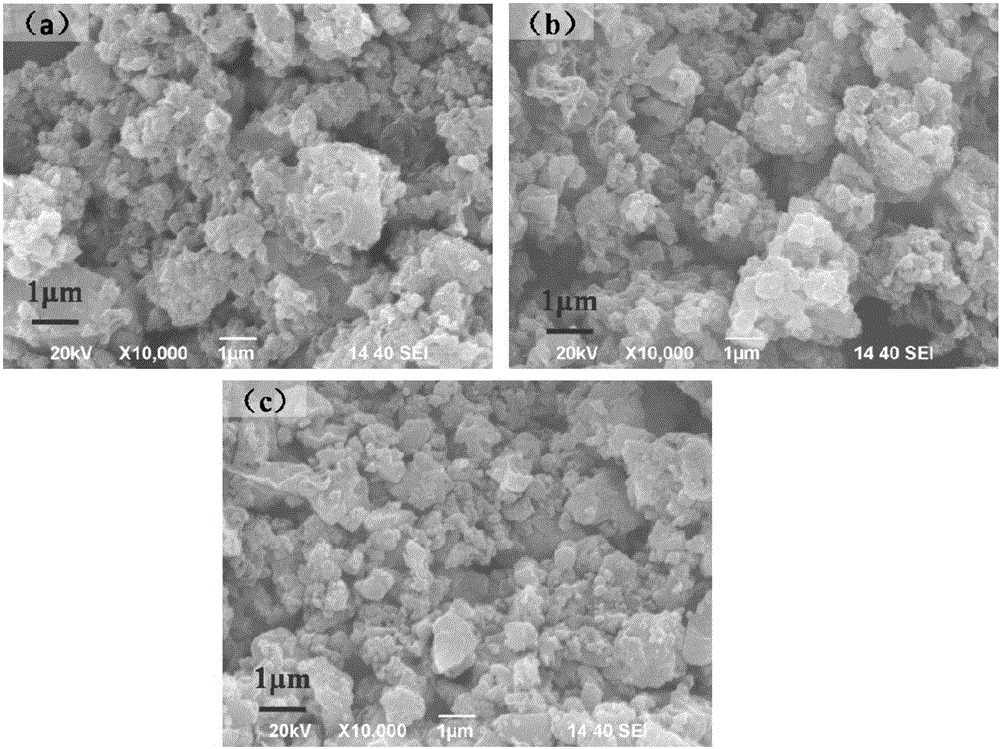

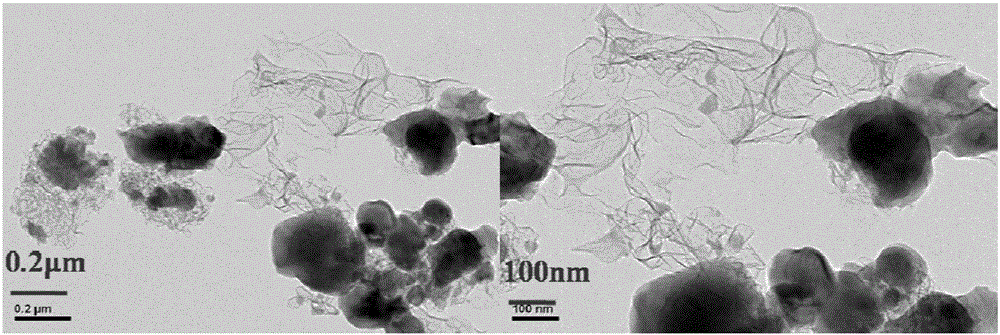

[0068] The resulting product was tested by XRD as a pure phase of Na 3 V 2 (PO 4 ) 3 , no characteristic peaks of graphene were detected, see figure 1 (a) in which, figure 1 For the Na synthesized in Example 1 3 V 2 (PO 4 ) 3 (a), t...

Embodiment 2

[0077] Mix 0.09mol sodium acetate, 0.09mol ammonium dihydrogen phosphate, and 0.06mol ammonium metavanadate, add 15wt% polyvinyl alcohol, add acetone ball mill to the ball mill tank for 12 hours to make it evenly mixed, and put the evenly mixed solution into Dry in an oven at 80°C to obtain a precursor; place the precursor in an argon-hydrogen atmosphere for pre-sintering, the pre-sintering temperature is 400°C, and the pre-sintering time is 6 hours to obtain a calcined powder; take 1g of the calcined powder and 15wt% The polyvinyl alcohol is mixed and ground evenly, placed in an argon-hydrogen atmosphere for the second step of sintering, the sintering temperature is 750°C, and the sintering time is 12 hours to obtain the finished powder.

[0078] The resulting product was tested by XRD as a pure phase of Na 3 V 2 (PO 4 ) 3 , the characteristic peaks of graphene were not detected see figure 1 (b) in figure 1 For the Na synthesized in Example 1 3 V 2 (PO 4 ) 3 (a), the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com