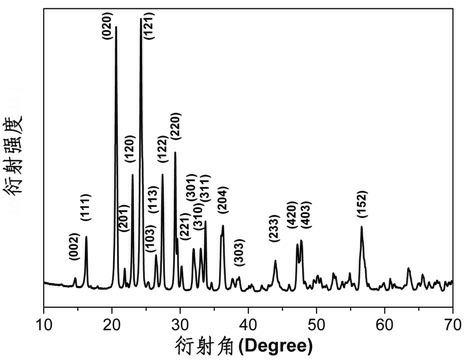

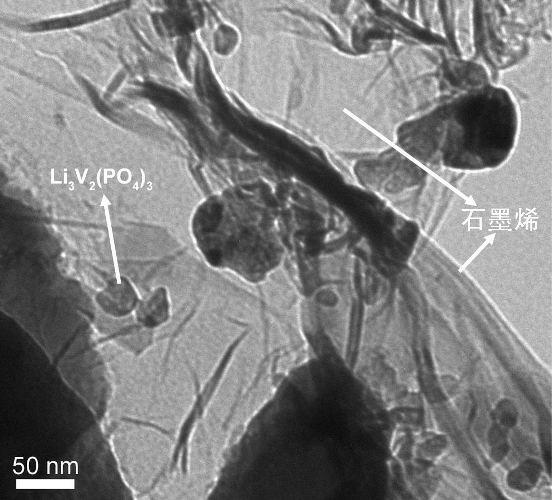

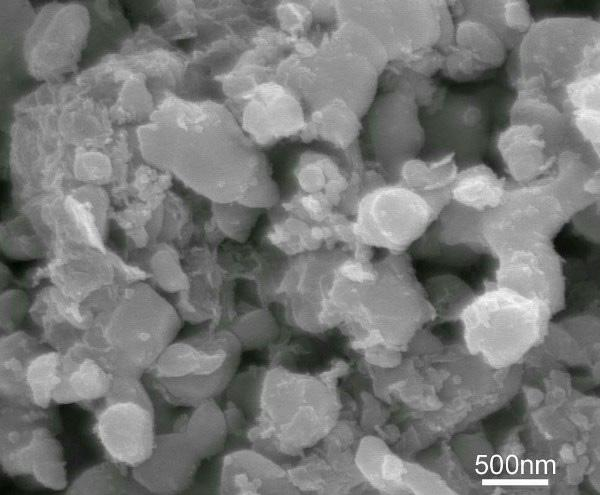

Lithium vanadium phosphate/graphene composite material and preparation method thereof

A technology of lithium vanadium phosphate and composite materials, which is applied in electrical components, battery electrodes, circuits, etc., can solve the problems of inability to effectively solve the problems of high-rate and sufficient electrical performance of lithium-ion batteries, and achieve the effect of simple and flexible preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Graphite oxide and deionized water were put into the container at a ratio of 1:10 (mg / mL), and after ultrasonication for 4 hours, a graphene oxide dispersion was obtained. After adding ascorbic acid solution, the ultrasonic wave was continued for 2 hours, and it was allowed to stand at room temperature for 20 hours to obtain Partially reduced graphene oxide dispersion in water as solvent. Add vanadium pentoxide and oxalic acid into deionized water at a molar ratio of 1:3, stir in a water bath at 80°C until dissolved, and then add Li 2 CO 3 and NH 4 h 2 PO 4 , continue to stir for 30min to obtain the precursor of lithium vanadium phosphate sol, which is added to the above-mentioned graphene oxide dispersion, wherein the mass ratio of lithium vanadium phosphate, graphene oxide and ascorbic acid is 40:1:1, continue to stir for 2h, and sonicate for 2h , dried at 80°C and ground, then pre-calcined at 350°C for 4 hours under nitrogen, and then calcined at 800°C for 8 hour...

Embodiment 2

[0025] Graphite oxide and deionized water were put into the container at a ratio of 1:5 (mg / mL). After ultrasonication for 4 hours, a graphene oxide dispersion was obtained. After adding 85% hydrazine hydrate, ultrasonication was continued for 4 hours to obtain a graphene oxide dispersion using water as a solvent. Partially reduced graphene oxide dispersion. Add vanadium pentoxide and oxalic acid into deionized water at a molar ratio of 1:3, stir in a water bath at 80°C until dissolved, and then add Li 2 CO 3 and NH 4 h 2 PO 4 , continue to stir for 30min to obtain the precursor of lithium vanadium phosphate sol, which is added to the above-mentioned graphene oxide dispersion, wherein the mass ratio of lithium vanadium phosphate, graphene oxide and hydrazine hydrate is 400:10:1, continue to stir for 2h, and ultrasonically 2h, dried at 80°C and ground, then pre-calcined at 350°C for 4h under nitrogen, and then calcined at 750°C for 12h to obtain lithium vanadium phosphate / g...

Embodiment 3

[0027] Graphite oxide and deionized water were put into a container at a ratio of 1:5 (mg / mL), and after ultrasonication for 4 hours, a graphene oxide dispersion was obtained. Add vanadium pentoxide and oxalic acid into deionized water at a molar ratio of 1:3, stir in a water bath at 80°C until dissolved, and then add Li 2 CO 3 and NH 4 h 2 PO 4, continue to stir for 30min, obtain the lithium vanadium phosphate sol precursor, join it in the above-mentioned graphene oxide dispersion liquid, continue ultrasonic 2h after adding the citric acid solution, wherein the mass ratio of vanadium phosphate lithium, graphene oxide and citric acid is 40: 1:4, continue to stir for 2 hours, dry at 80°C and grind, then pre-calcine at 350°C for 4 hours under argon, and then calcinate at 850°C for 4 hours to obtain lithium vanadium phosphate / graphene composite material. The graphene content in the sample was 2.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com