Lithium ion cell anode material lithium vanadium phosphate and preparation method thereof

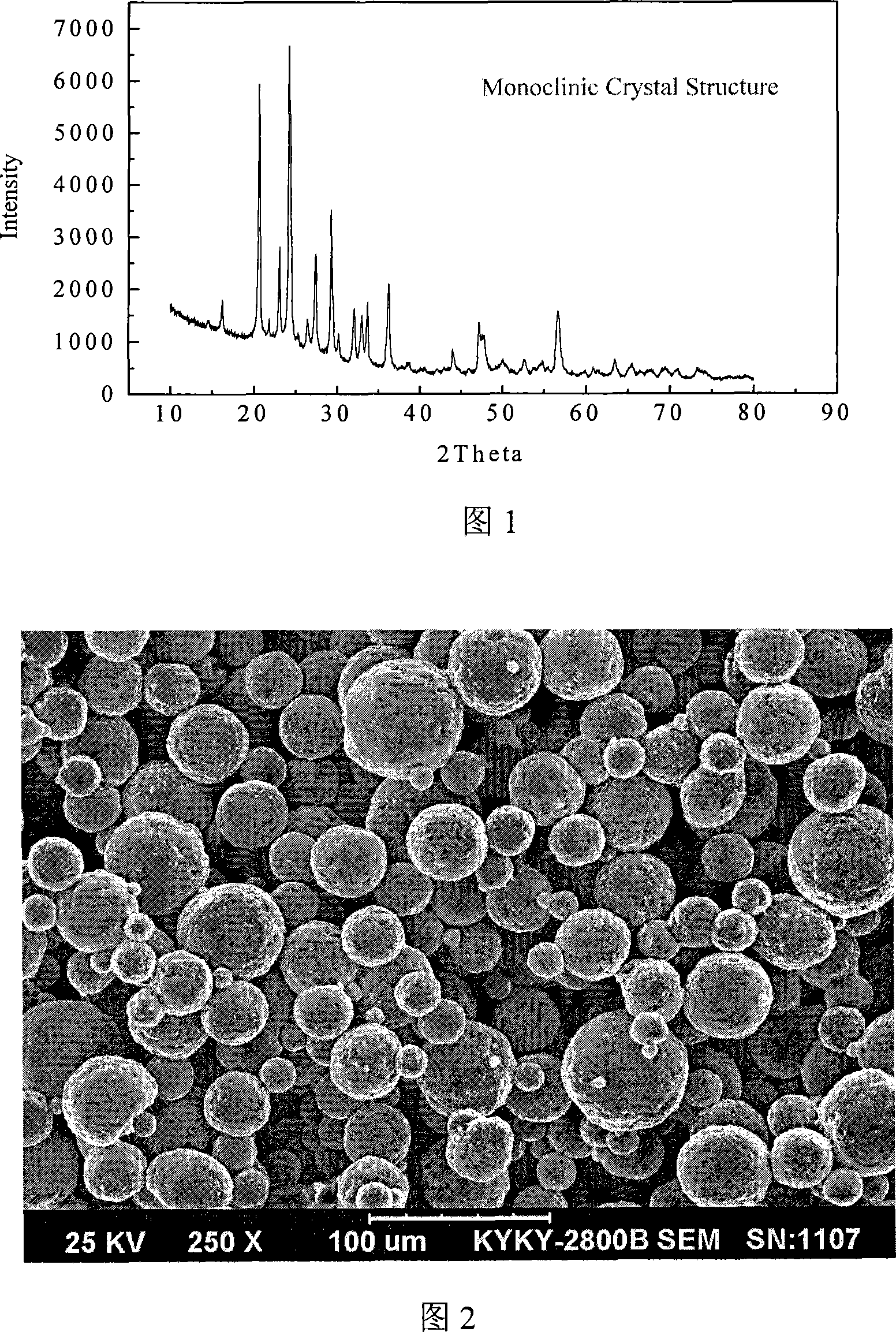

A lithium-ion battery and cathode material technology, applied in the field of lithium vanadium phosphate material and its preparation, can solve the problem that the conductivity and high-rate discharge performance of lithium vanadium phosphate cathode material cannot meet the rate performance requirements of lithium-ion batteries, and the heating temperature and time are not easy Control, product purity can not be guaranteed and other issues, to achieve the effect of excellent rate discharge performance, excellent cycle stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of lithium vanadium phosphate lithium ion battery cathode material of the present invention adopts the following steps:

[0031] 1. Preparation of nanoparticles: the water-insoluble lithium source compound, vanadium source compound, phosphorus source compound and complexing agent are processed into nano-sized particles through wet ultrafine ball milling; ball milling or crushing equipment is used, and the ball milling or crushing equipment is Stirring ball mill, sand mill, colloid mill, jet mill, impact micronizer, jet vortex mill, impact mill or rod mechanical mill.

[0032] 2. Liquid phase mixing reaction: weigh the lithium source compound and the vanadium source compound according to the ratio of the amount of substances Li:V:P:L (complexing agent)=(3.0~3.3):2:3:(1.5~2.2) , phosphorus source compound and complexing agent are dissolved in deionized water at 40-90°C, and stirred for 1-3 hours to obtain a mixed material; 40-90°C deionized water, ...

Embodiment 1

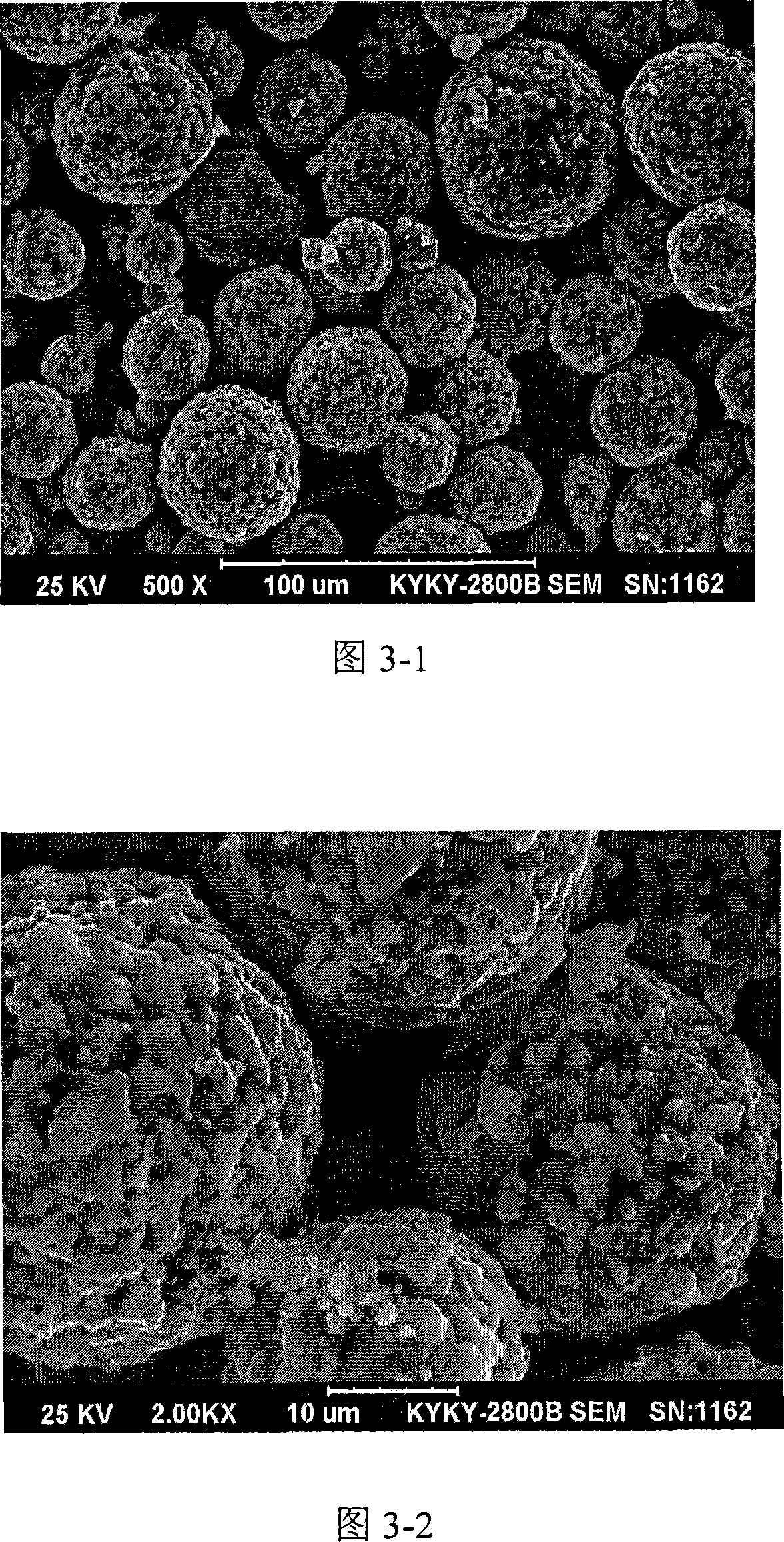

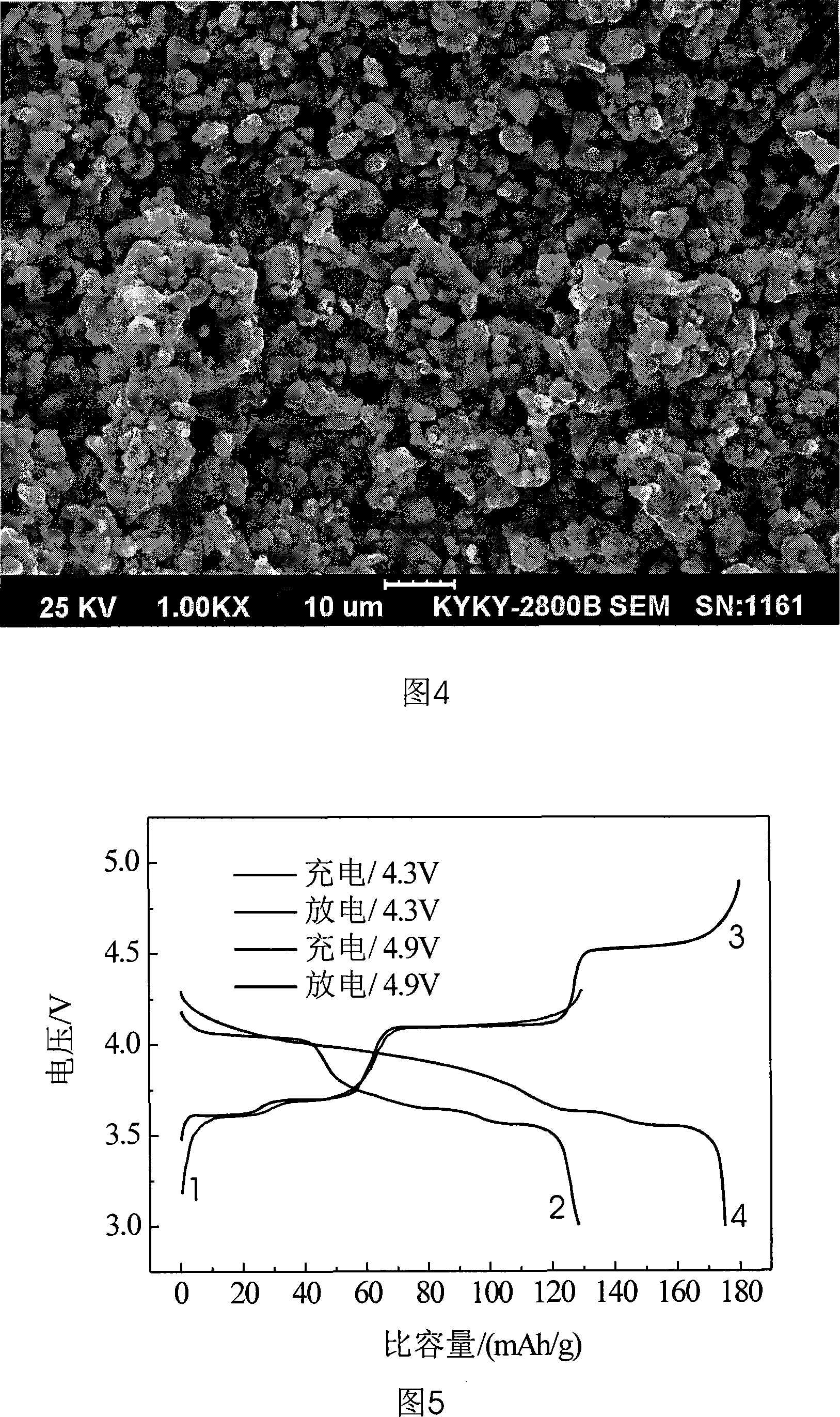

[0044] The raw materials lithium carbonate, ammonium metavanadate, and glucose were respectively pulverized by a circulating stirring ball mill until the particle size was on the order of nanometers, and lithium carbonate (Li 2 CO 3 ) 108.8 grams, ammonium metavanadate (NH 4 VO 3 ) 229.6 grams, phosphoric acid (H 3 PO 4 ) 339.4 grams and 353.2 grams of glucose were respectively dissolved in 400 milliliters of deionized water at 60° C., and stirred at a constant temperature for 3 hours; the glucose solution was first added to the phosphoric acid solution, then lithium carbonate and ammonium metavanadate solution were added successively, and stirred at a constant temperature of 60° C. for 2 Hours until the reaction of the mixed solution is complete and no bubbles are produced.

[0045] The above sample was ball milled (QM-1SP4 planetary ball mill) at a speed of 300r / min for 1 hour, spray-dried and granulated in a centrifugal spray granulation dryer at 100°C, and then placed th...

Embodiment 2

[0048] The raw materials lithium hydroxide, vanadium pentoxide, ammonium dihydrogen phosphate and citric acid were pulverized to the nanometer scale through ball milling, and lithium hydroxide (LiOH·H 2 O) 87.52 grams, vanadium pentoxide (V 2 o 5 ) 138.10 g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 256.52 grams and citric acid 309.32 grams. Dissolve citric acid in 1700 ml of deionized water at 80°C and stir at constant temperature for 3 hours; mix lithium hydroxide, vanadium pentoxide and ammonium dihydrogen phosphate and ball mill for 0.5 hours at a speed of 300r / min, then add the mixture to lemon acid solution, stirred at 80°C for 3 hours until the reaction was complete.

[0049] The above sample was ball milled at a speed of 400r / min for 1 hour, spray-dried and granulated at 300°C, and then placed in a tube furnace under the protection of argon for 4 hours at 350°C, and cooled naturally to obtain Precursor of lithium vanadium phosphate.

[0050] The precursor o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com