Recycling method of waste foamed magnesium

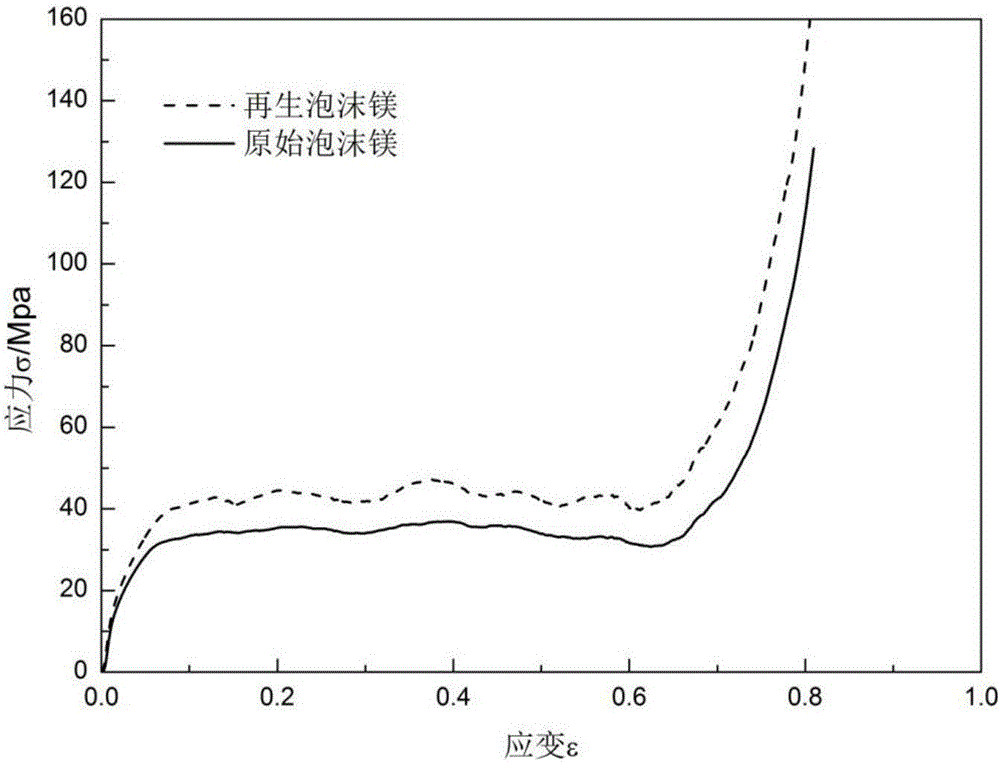

A technology for filtering waste foam and foam ceramics, applied in the direction of improving process efficiency, can solve problems such as complex process, harm to human health, environmental pollution, etc., and achieve the effect of simple process and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

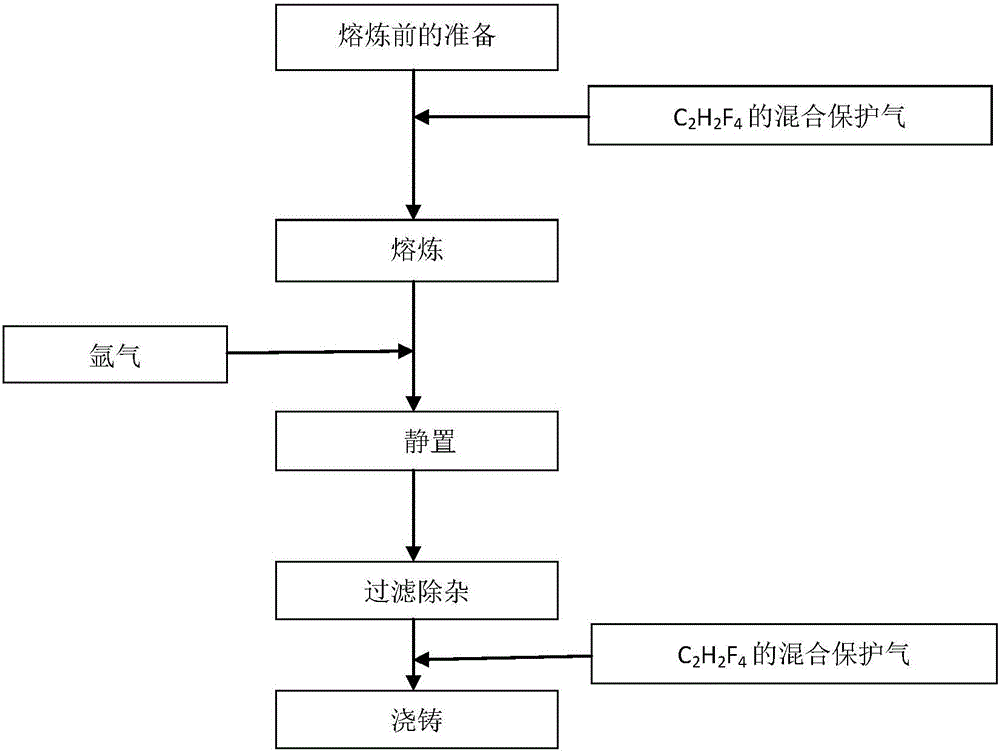

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Cut the waste foamed magnesium into 20mm×20mm×10mm blocks. The cut blocks are ultrasonically oscillated with acetone for 20 minutes, then cleaned with alcohol, and finally dried with a hair dryer. Weigh 500g of dried waste foamed magnesium ;

[0028] Step 2: Preheat the crucible to 400°C in a resistance furnace, then put the waste magnesium foam weighed in the first step into the preheated crucible, raise the temperature to 650°C, and feed the protective gas at the same time, (selected protective gas The volume ratio in air:CO 2 :C 2 h 2 f 4=375:124:1; the composition of the shielding gas in the fourth step below is the same), and the waste foamed magnesium is melted and then incubated for 5min;

[0029] Step 3: Stop passing the protective gas, use the rotary nozzle to inject argon gas into the melt, the ventilation speed is 5L / min, the rotation speed of the nozzle is 240r / min, the time is 3min, and then stand still for 8min, and then remove the melt inclus...

Embodiment 2

[0037] Step 1: Cut waste magnesium foam into blocks of 10mm×10mm×10mm. The cut blocks are ultrasonically oscillated with acetone for 30 minutes, then cleaned with alcohol, and finally dried with a hair dryer. Weigh 500g of dried waste magnesium foam ;

[0038] Step 2: Preheat the crucible to 450°C in a resistance furnace, then put the waste magnesium foam weighed in the first step into the preheated crucible, raise the temperature to 680°C, and feed the protective gas at the same time, (selected protective gas The volume ratio of the air:CO 2 :C 2 h 2 f 4 =150:49:1, the composition of the shielding gas in the fourth step below is the same) after the waste foamed magnesium is melted, it is kept for 10min;

[0039] Step 3: Stop passing the protective gas, use the rotary nozzle to inject argon gas into the melt, the ventilation speed is 8L / min, the rotation speed of the nozzle is 360r / min, the time is 5min, and then stand still for 10min, and then remove the melt inclusions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com