A kind of preparation method of boron nitride nanosheet/ferroferric oxide magnetic nanocomposite material

A technology of triiron tetroxide and magnetic nanometer, which is applied in the field of preparation of nanocomposite materials, can solve the problems of complex method, increase energy consumption, increase reaction cost, etc., and achieve the effects of simple preparation process, stable structure and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

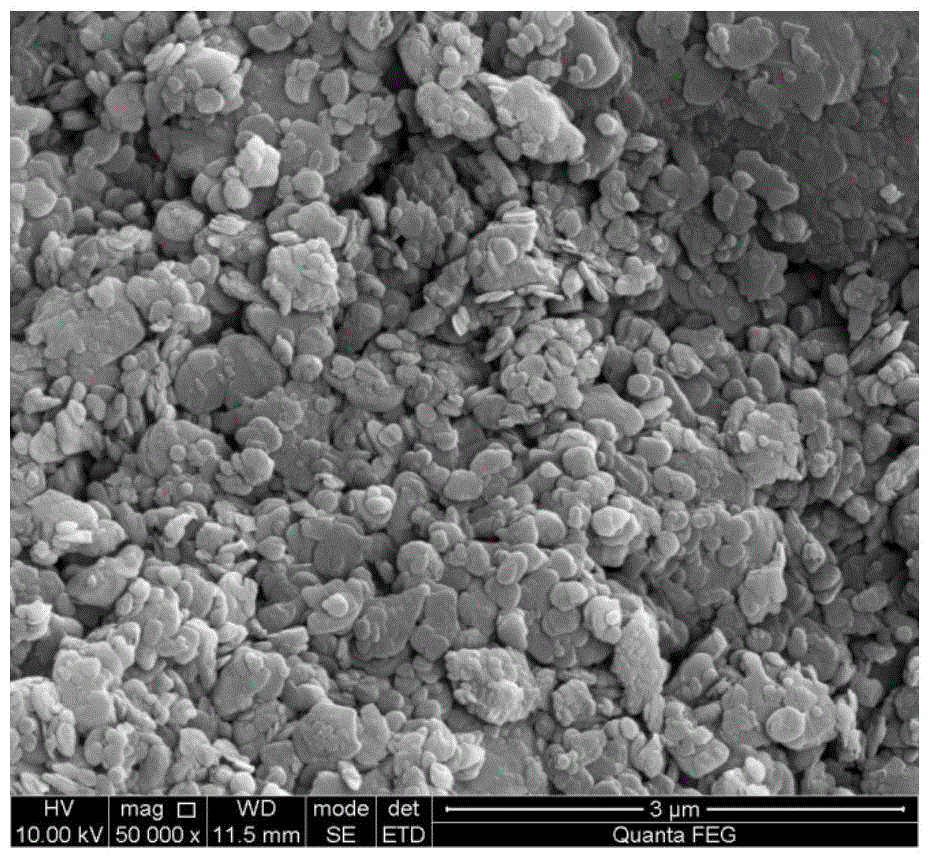

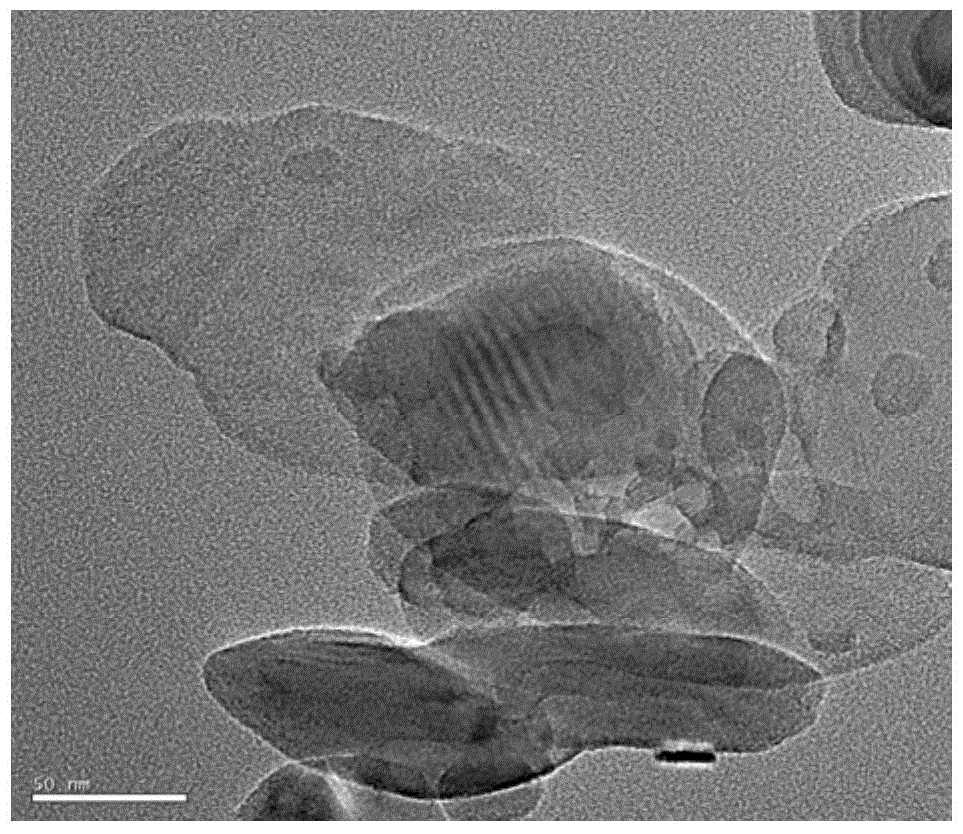

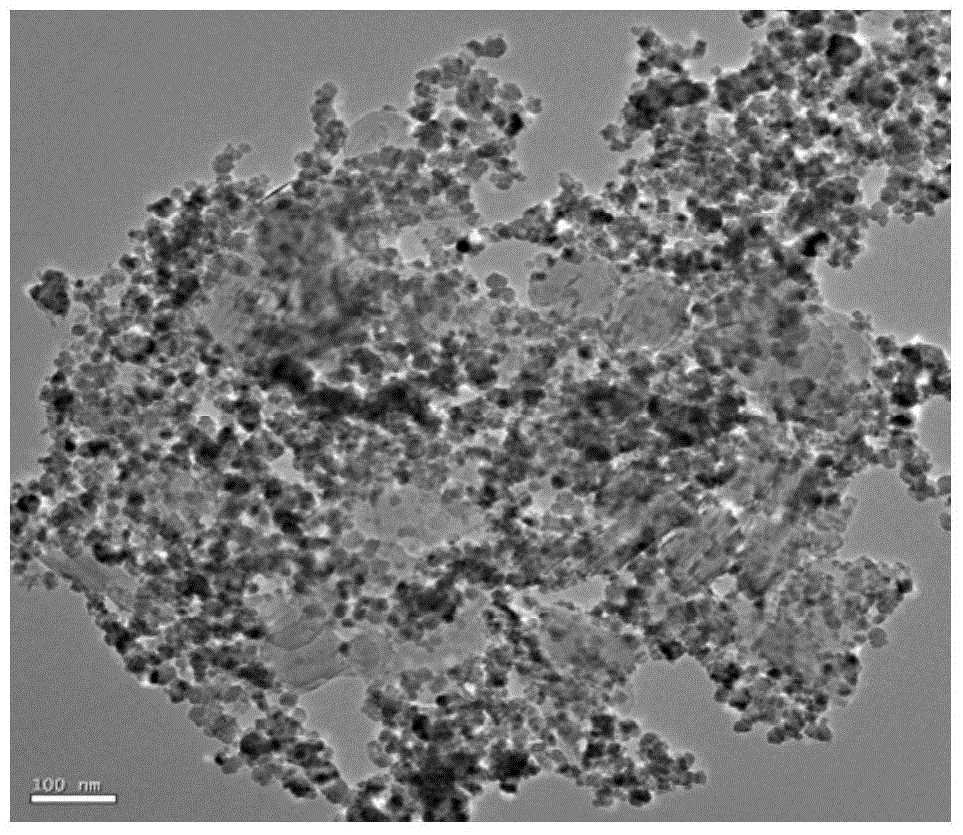

[0018] Specific embodiment one: the preparation method of a kind of boron nitride nanosheet / ferroferric oxide magnetic nanocomposite material of the present embodiment is carried out according to the following steps:

[0019] 1. Disperse 1g to 6g of hexagonal boron nitride powder in 100mL to 400mL of mixed acid. Stir continuously for 10h to 60h at a temperature of 50°C to 100°C and a speed of 1000rpm to 1500rpm. The obtained mixture is then used Wash the mixture with deionized water to neutrality, and then dry it at 80°C to 100°C to obtain intercalated boron nitride; wherein, the mixed acid is composed of concentrated H 2 SO 4 and concentrated HNO with a mass concentration of 95% 3 Composition by volume ratio of 1 to 3:1;

[0020] 2. Disperse 0.1g ~ 1.5g of intercalated boron nitride obtained in step 1 in 50mL ~ 200mL of isopropanol, at room temperature, ultrasonically treat for 5h ~ 20h, and then centrifuge at a speed of 1500rpm ~ 6000rpm for 15min ~50min, take the superna...

specific Embodiment approach 2

[0027] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the temperature is 50° C. and the rotation speed is 1500 rpm, and the stirring is continued for 15 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the mixed acid described in step one is made of concentrated H with a mass concentration of 98%. 2 SO 4 and concentrated HNO with a mass concentration of 95% 3 Composition by volume ratio of 3:1. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com