Preparation method of lithium vanadium phosphate (Li3V2(PO4)3)/graphene composite material for positive electrode of lithium ion battery

A lithium-ion battery, lithium vanadium phosphate technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problems of poor electrochemical performance, complicated operation, low synthesis temperature, etc., to improve electronic conductivity, simple preparation process, The effect of suppressing excessive growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

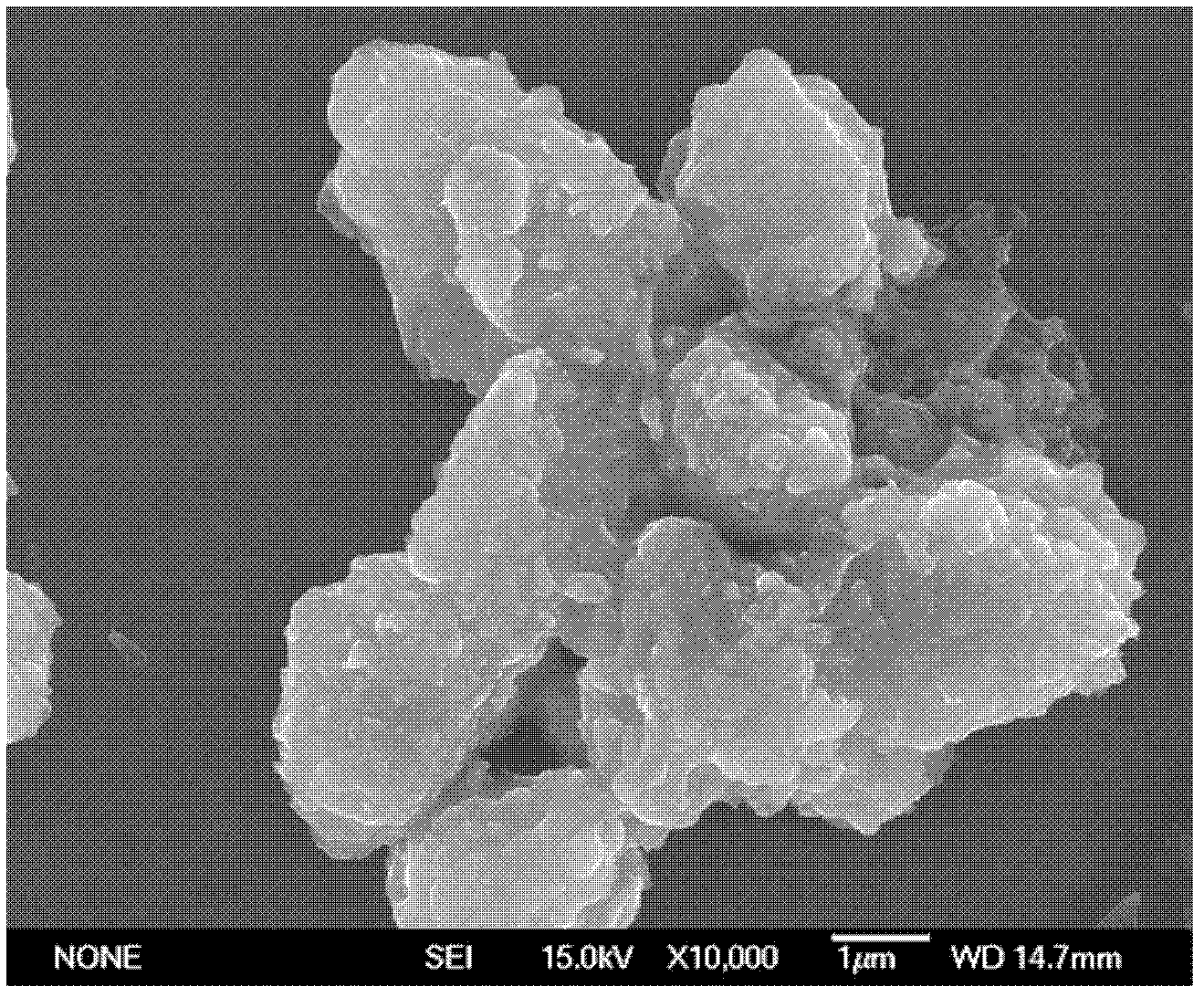

[0029] Weigh LiNO according to the stoichiometric ratio of Li:V:P molar ratio of 3:2:33 , V 2 o 5 and NH 4 h 2 PO 4 A total of 20g, uniformly mixed with 2.5g graphene oxide precursor by magnetic stirring, stirred for 2h, continued to stir for 0.5h after adding 2.5g citric acid, then sprayed dry by spray dryer to obtain powder material, then transferred the gained material to Into a tube furnace, in an argon atmosphere, heated at a heating rate of 30°C / min, with an argon flow rate of 100mL / min, and calcined at a constant temperature of 200°C for 1h. After natural cooling, the obtained precursor powder was ground for 50 minutes, then transferred to a tube furnace, heated at a heating rate of 30°C / min, with a gas flow rate of 100mL / min, and calcined at a constant temperature of 850°C for 10 hours to obtain a lithium-ion battery lithium vanadium phosphate positive electrode Material. It is measured that the primary particle diameter of the material obtained by spray granulati...

Embodiment 2

[0032] Weigh CH according to the stoichiometric ratio of Li:V:P=3:2:3 3 COOLi, NH 4 VO 3 and (NH 4 ) 2 HPO 4 A total of 20g, mixed uniformly with an aqueous solution containing 1.5g graphite oxide (3mg / mL) by magnetic stirring, stirred for 3h, continued to stir for 1h after adding 2.8g sucrose, then spray-dried by a spray dryer to obtain a powder material, and then The obtained material was transferred into a tube furnace, heated at a heating rate of 20°C / min in a hydrogen atmosphere, the hydrogen flow rate was 80mL / min, and calcined at a constant temperature of 250°C for 2h. After natural cooling, the obtained precursor powder was ground for 30 minutes, then transferred to a tube furnace, heated at a heating rate of 20°C / min, with a gas flow rate of 80mL / min, and calcined at a constant temperature of 800°C for 8 hours to obtain a lithium-ion battery lithium vanadium phosphate positive electrode Material.

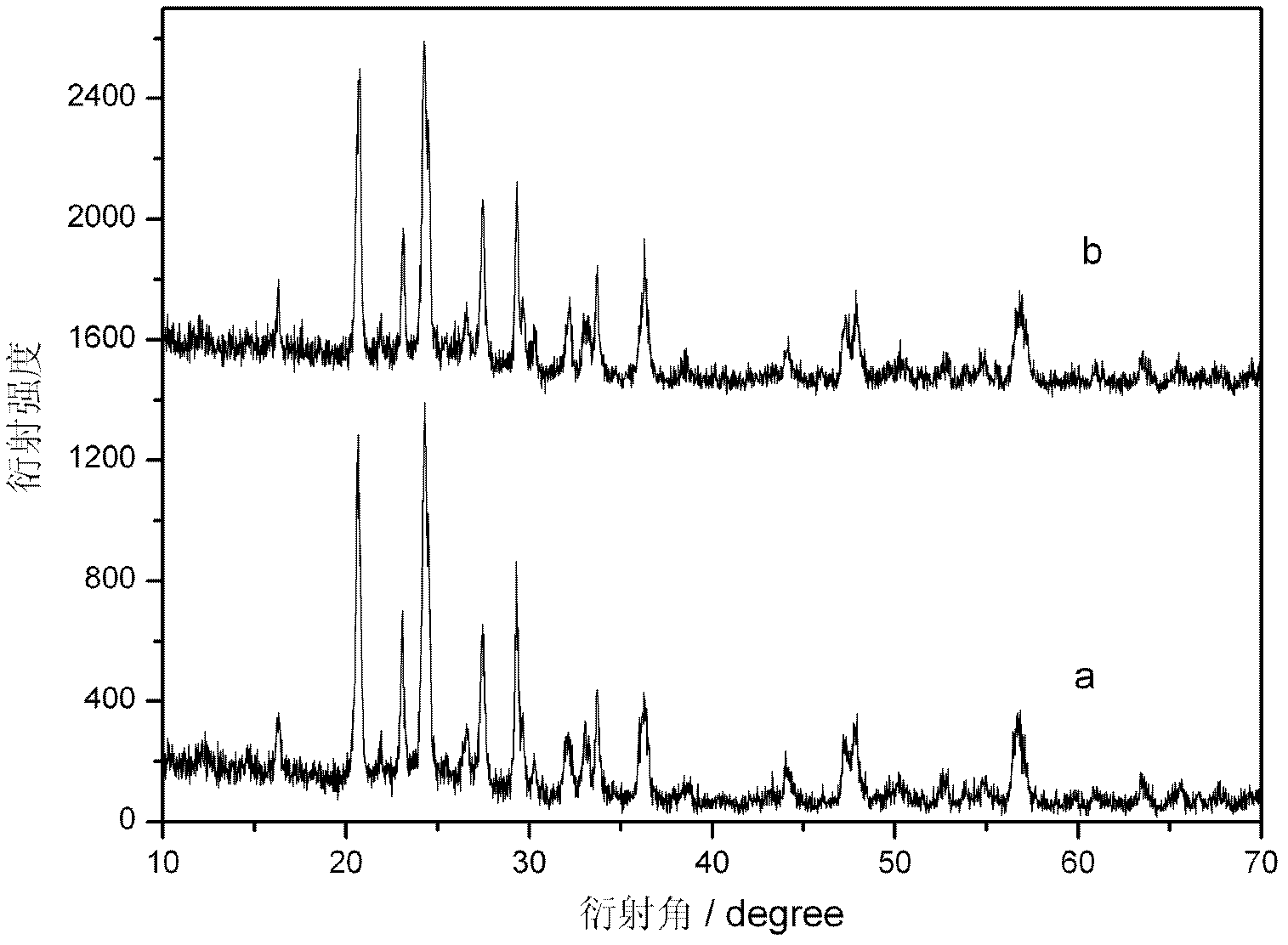

[0033] The XRD of the product see figure 1 As shown in the midd...

Embodiment 3

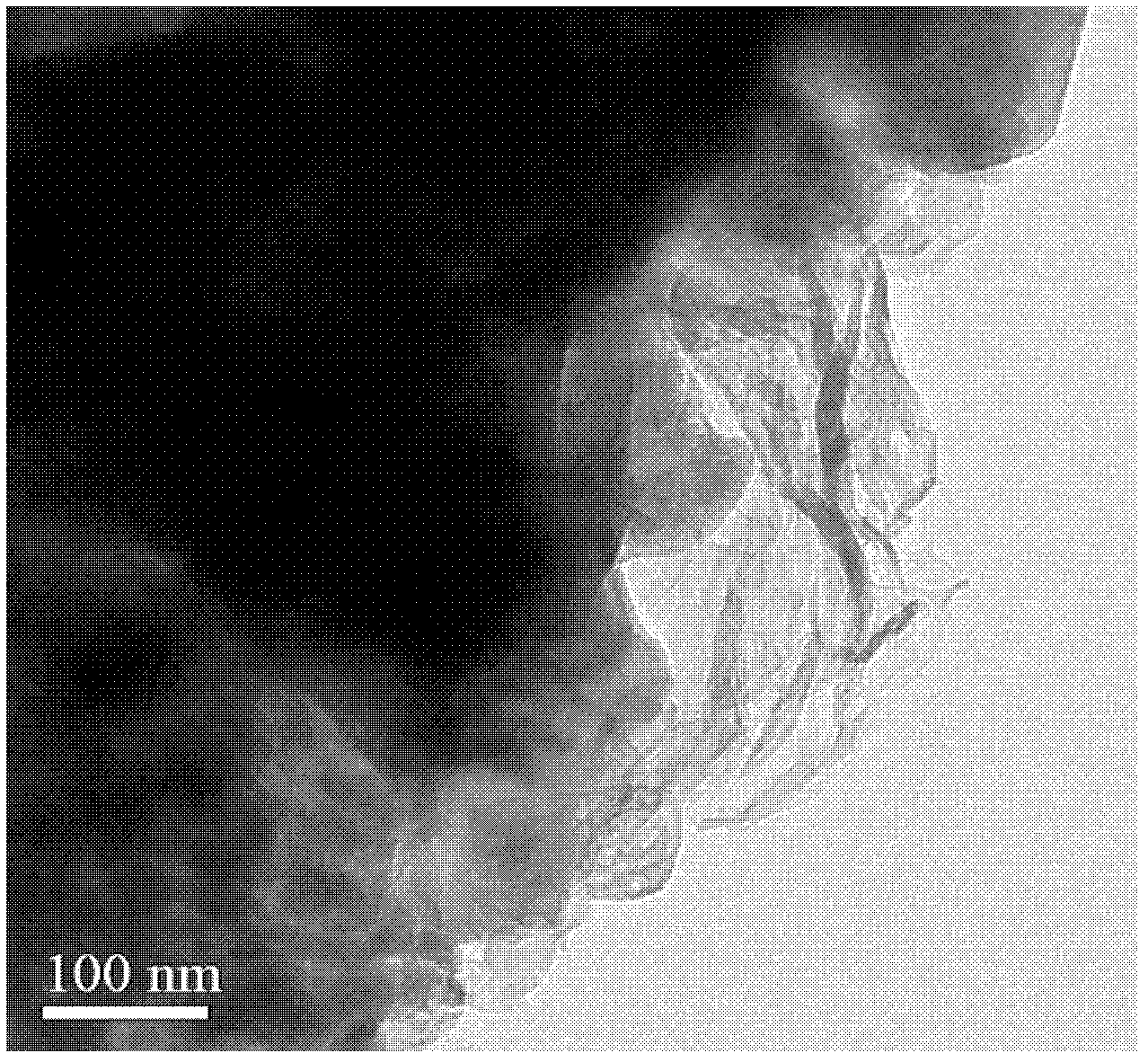

[0035] Weigh LiOH·H according to the stoichiometric ratio of Li:V:P=3:2:3 2 O, NaVO 3 and H 3 PO 4 A total of 25g, mixed uniformly with 3.7g pyrolytic graphene (400°C×2h) precursor by magnetic stirring, stirred for 3h, added 2.6g polyvinyl alcohol and continued to stir for 1.5h, and then spray dried by a spray dryer to obtain The powder material was then transferred to a tube furnace, heated in an ethylene atmosphere at a heating rate of 20°C / min, with an ethylene flow rate of 60mL / min, and calcined at a constant temperature of 350°C for 3h. After natural cooling, the obtained precursor powder was ground for 20 minutes, then transferred to a tube furnace, heated at a heating rate of 25°C / min, with a gas flow rate of 60mL / min, and calcined at a constant temperature of 700°C for 6 hours to obtain a lithium-ion battery lithium vanadium phosphate positive electrode Material. The average particle size of the material is measured to be 100-200nm, and the tap density is 1.60g / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com