Sodium vanadium fluorophosphate, and preparation method and use thereof

A technology of vanadium sodium fluorophosphate and vanadium source, applied in the field of preparation of vanadium sodium fluorophosphate Na32F3-2x, which can solve the problems of complex process, high solubility requirements of raw materials, long ball milling time, etc., and achieve good cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

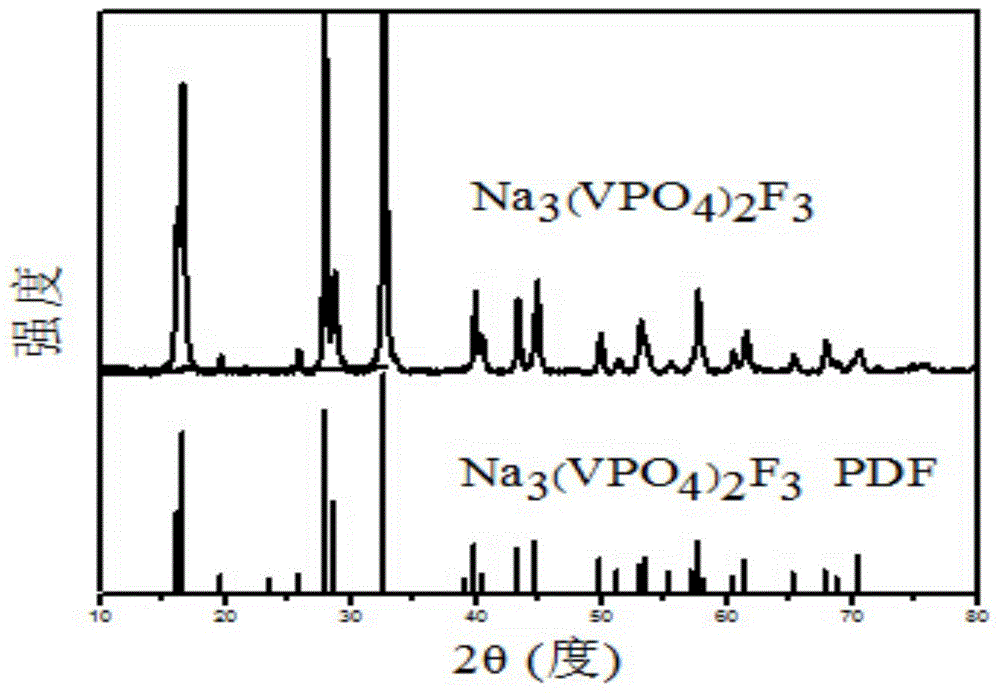

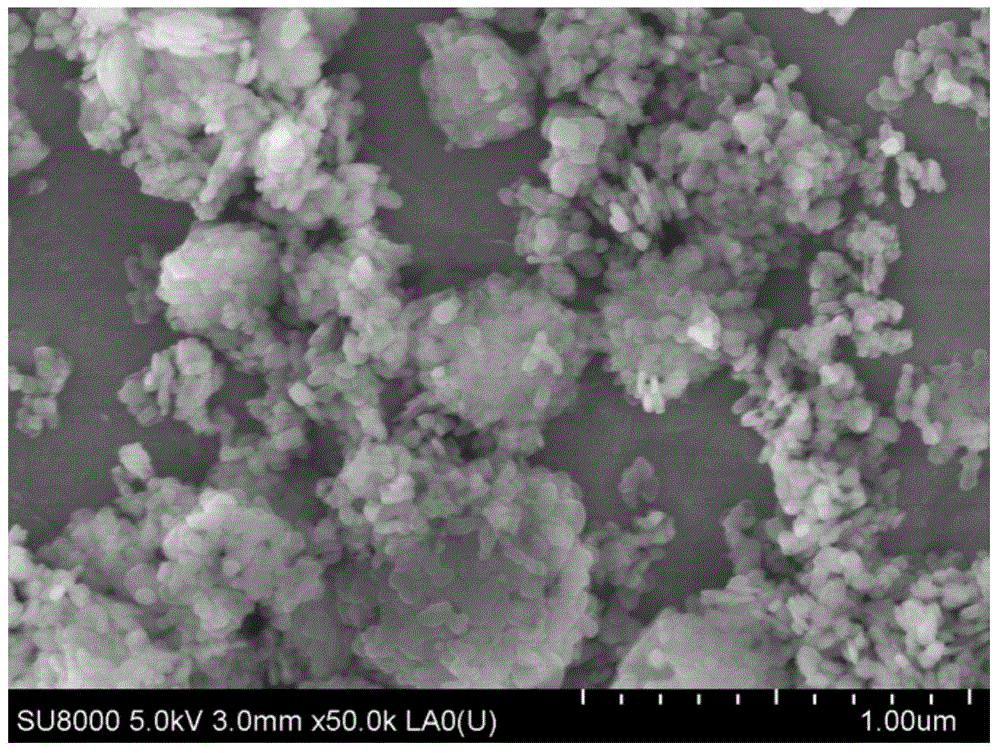

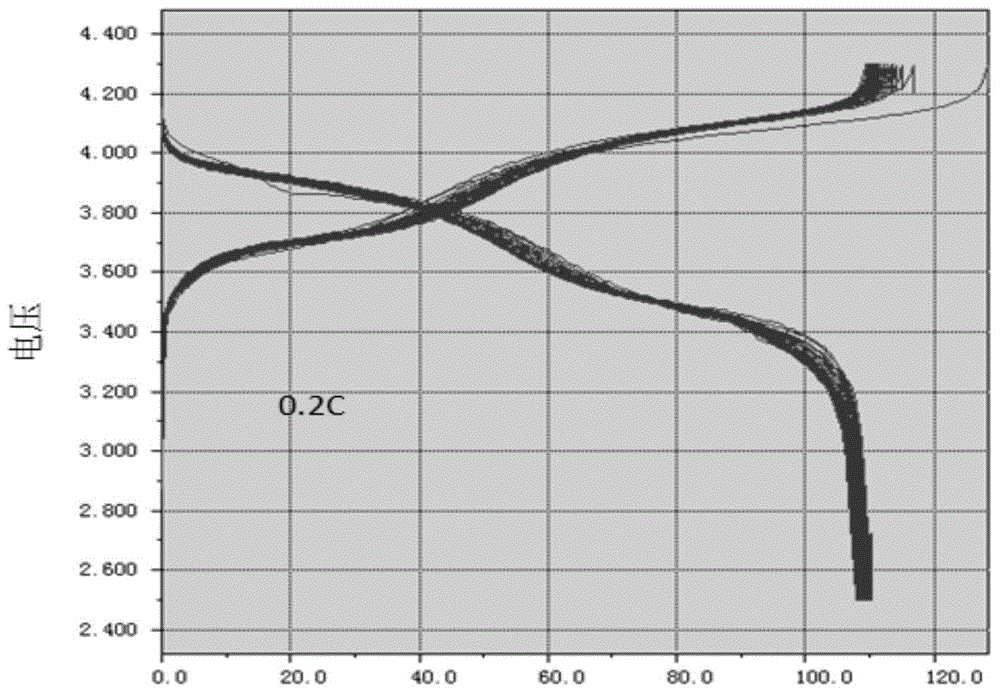

[0040] 0.359g vanadium acetylacetonate, 104uL concentrated phosphoric acid (85%), and 0.072g sodium fluoride (Na:V:P:F about 1.6:1:1.5:1.6) were ultrasonically dispersed in 3mL ethanol and 1mL acetone to obtain a mixed Uniform reaction materials; transfer the above-mentioned homogeneously mixed materials into a hydrothermal reaction kettle, raise the temperature to 100°C at a rate of 5°C per minute, and keep the temperature at this temperature for 10h, and the product is alternately washed with a certain amount of ethanol and water 6 times, dried in air at 65°C for 3 hours, and weighed to obtain 0.207g of product, the yield was close to 100%. XRD shows that the product is Na 3 (VPO 4 ) 2 f 3 , has the characteristics of good crystallinity and high purity, its XRD and SEM are as follows Figure 1-2 shown. and synthesized Na 3 (VPO 4 ) 2 f 3 As a positive electrode, use metal sodium as a negative electrode, assemble a button battery, and measure its charge and discharge...

Embodiment 2

[0042] 0.274g vanadyl acetylacetonate, 83uL concentrated phosphoric acid (85%), 0.072g sodium fluoride (Na:V:P:F about 1.6:1:1.2:1.6) were ultrasonically dispersed in 3mL ethanol and 1mL acetone to obtain Mixed uniform reaction materials; transfer the above-mentioned uniformly mixed materials into a hydrothermal reaction kettle, raise the temperature to 120°C at a rate of 5°C per minute, and keep the temperature at this temperature for 10h, and the product is passed through a certain amount of ethanol and water alternately Washed 8 times, dried in the air at 65° C. for 3 h, and weighed 0.201 g of the product, the yield was close to 100%. XRD shows that the product is Na 3 (VOPO 4 ) 2 F, has the characteristics of good crystallinity and high purity, its XRD and SEM are as follows Figure 4-5 shown. and synthesized Na 3 (VPO 4 ) 2 f 3 As a positive electrode, use metal sodium as a negative electrode, assemble a button battery, and measure its charge and discharge curve a...

Embodiment 3

[0044] Ultrasonic disperse 0.180g vanadium acetylacetonate, 0.137g vanadyl acetylacetonate, 104uL concentrated phosphoric acid (85%), 0.072g sodium fluoride (Na:V:P:F about 1.6:1:1.5:1.6) in 3mL ethanol and 1mL of acetone to obtain a uniformly mixed reaction material; transfer the above-mentioned uniformly mixed material into a hydrothermal reaction kettle, raise the temperature to 110°C at a heating rate of 5°C per minute, and keep the temperature at this temperature for 24h. The amount of ethanol and water was washed alternately for 6 times, dried in air at 65° C. for 3 h, and 0.206 g of product was obtained by weighing, with a yield close to 100%. XRD shows that the product is Na 3 (VO 0.5 PO 4 ) 2 f 2 , has the characteristics of good crystallinity and high purity, its XRD and SEM are as follows Figure 7-8 shown. and synthesized Na 3 (VPO 4 ) 2 f 3 As a positive electrode, use metal sodium as a negative electrode, assemble a button battery, and measure its charg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com