Preparation method of carbon coated vanadium sodium phosphate positive electrode material

A technology of sodium vanadium phosphate and cathode material, applied in battery electrodes, electrical components, non-aqueous electrolyte batteries, etc., can solve problems such as poor material performance, and achieve the effects of excellent electrochemical performance, reduced side reactions, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 5gNH 4 VO 3 , 10gNaH 2 PO 4 2H 2 O and 3.75g of glucose were placed in a ball mill jar, then 100mL of water was added as a dispersant, and at 250kHz, ultrasonically mixed for 2 hours, and then ball milled at a speed of 250r / min for 7 hours to obtain a yellow suspension; (2) Step (1) ) The obtained yellow suspension is spray-dried in a spray dryer with the air inlet temperature at 180°C, the air outlet temperature at 130°C, and the feed rate at 10mL / min to obtain a powdery precursor; (3) the step ( 2) The obtained powdery precursor was first calcined at 350°C for 4 hours under high-purity argon gas, and then calcined at 700°C for 8 hours to obtain a carbon-coated sodium vanadium phosphate cathode material.

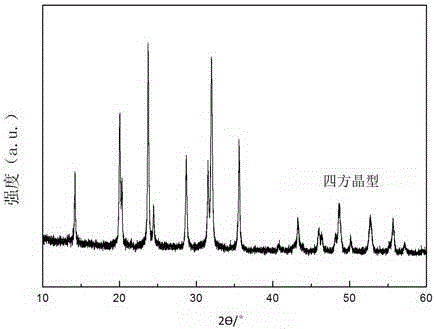

[0032] Such as figure 1 As shown, the obtained carbon-coated sodium vanadium phosphate positive electrode material has high crystallinity and complete crystal form, and what is detected is the pure phase of sodium vanadium phosphate.

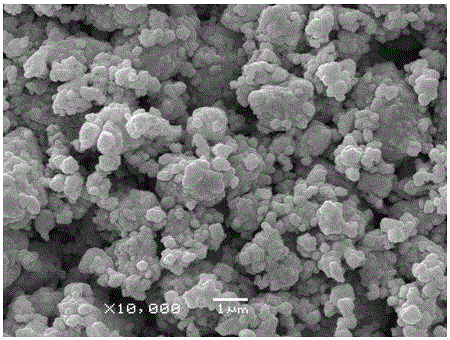

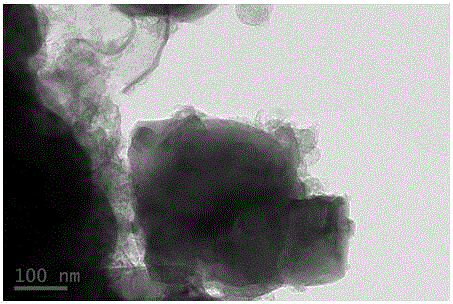

[0033] Such as ...

Embodiment 2

[0039] (1) Add 5gNH 4 VO 3 , 10gNaH 2 PO 4 2H 2 O and 2.5g of glucose were placed in a ball mill jar, then 100mL of water was added as a dispersant, and ultrasonically mixed for 4 hours at 50kHz, and then ball milled at a speed of 200r / min for 4 hours to obtain a yellow suspension; (2) Step (1) ) The obtained yellow suspension is spray-dried in a spray dryer with the air inlet temperature at 150°C, the air outlet temperature at 120°C, and the feed rate at 5mL / min to obtain a powdery precursor; (3) the step ( 2) The obtained powdery precursor was first calcined at 300°C for 3h and then at 600°C for 6h under high-purity argon gas to obtain a carbon-coated sodium vanadium phosphate positive electrode material.

[0040] Battery assembly: take 0.24g Na obtained in this embodiment respectively 3 V 2 (PO 4 ) 3 The material is used as the positive electrode material, adding 0.03g acetylene black (SP) as the conductive agent and 0.03g PVDF (HSV-900) as the binder, after fully g...

Embodiment 3

[0042] (1) Add 5gNH 4 VO 3 , 10gNaH 2 PO 4 2H 2 0 and 5g of glucose were placed in a ball mill jar, then 100mL of water was added as a dispersant, and ultrasonically mixed for 0.5h at 400kHz, and then ball milled at a speed of 300r / min for 10h to obtain a yellow suspension; (2) Step (1) ) The obtained yellow suspension is spray-dried in a spray dryer with the air inlet temperature at 200°C, the air outlet temperature at 150°C, and the feed rate at 20mL / min to obtain a powdery precursor; (3) Step ( 2) The obtained powdery precursor was calcined at 400°C for 5 hours under high-purity argon gas, and then calcined at 750°C for 10 hours to obtain a carbon-coated sodium vanadium phosphate cathode material.

[0043] Battery assembly: take 0.24g Na obtained in this embodiment respectively 3 V 2 (PO 4 ) 3 The material is used as the positive electrode material, adding 0.03g acetylene black (SP) as the conductive agent and 0.03g PVDF (HSV-900) as the binder, after fully grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com