Nano and microstructure lithium ion battery anode material ti 2 c microspheres and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, which is applied to battery electrodes, secondary batteries, structural parts, etc., can solve the problems of increased side reactions between electrodes and electrolytes, decreased battery volumetric energy density, and poor material stability. Effects of reduced side reactions, good cycle performance, and short diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

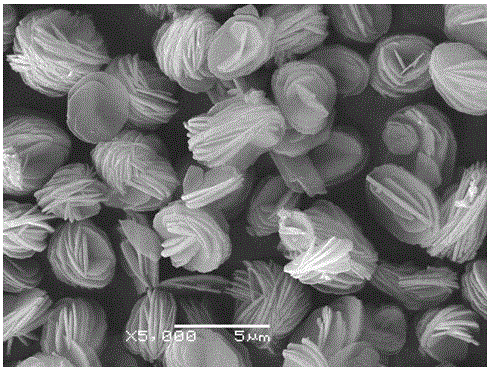

[0025] (1) Put 1g Ti 2 The AlC matrix material is immersed in 500mL HF solution with a concentration of 0.02mol / L for 70h to remove the metal Al layer by chemical etching, and a multi-layer two-dimensional Ti 2 C mixed solution;

[0026] (2) The obtained step (1) contains multi-layer two-dimensional Ti 2 The mixed solution of C is placed in an ultrasonic wave at a frequency of 60kHz, ultrasonicated for 100h, and mechanically exfoliated to obtain a monolayer of two-dimensional Ti 2 A mixed solution of C nanosheets;

[0027] (3) The obtained step (2) contains a single layer of two-dimensional Ti 2 The mixed solution of C nanosheets is placed in a polytetrafluoroethylene tank, heated to 200°C, sealed for 20 hours, and filtered to obtain nanostructured Ti 2 C microspheres;

[0028] (4) The nanostructured Ti obtained in step (3) 2 C microspheres were dried at 90°C for 10 hours to obtain Ti 2 C microspheres.

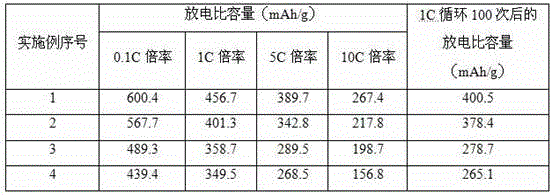

[0029] After testing, nano-microstructure lithium-ion battery ano...

Embodiment 2

[0033] (1) Put 2g of two-dimensional Ti 2 The AlC matrix material is immersed in 500mL HF solution with a concentration of 0.05mol / L for 10h to remove the metal Al layer by chemical etching, and a multi-layer two-dimensional Ti 2 C mixed solution;

[0034] (2) The obtained step (1) contains multi-layer two-dimensional Ti 2 The mixed solution of C is placed in an ultrasonic wave at a frequency of 80kHz, ultrasonicated for 50h, and mechanically exfoliated to obtain a monolayer of two-dimensional Ti 2 A mixed solution of C nanosheets;

[0035] (3) The obtained step (2) contains a single layer of two-dimensional Ti 2 The mixed solution of C nanosheets was placed in a polytetrafluoroethylene tank, heated to 250°C, sealed for 40 hours, and filtered to obtain nanostructured Ti 2 C microspheres;

[0036] (4) The nanostructured Ti obtained in step (3) 2 Dry the C microspheres at 60°C for 30 hours to obtain Ti 2 C microspheres.

[0037] After testing, nano-microstructure lithium...

Embodiment 3

[0041] (1) Add 3g of two-dimensional Ti 2 The AlC matrix material is immersed in 500mL HF solution with a concentration of 0.1mol / L for 50h to remove the metal Al layer by chemical etching, and a multi-layer two-dimensional Ti 2 C mixed solution;

[0042] (2) The obtained step (1) contains multi-layer two-dimensional Ti 2 The mixed solution of C is placed in an ultrasonic wave at a frequency of 100kHz, ultrasonicated for 5h, and mechanically exfoliated to obtain a single layer of two-dimensional Ti 2 A mixed solution of C nanosheets;

[0043] (3) The obtained step (2) contains a single layer of two-dimensional Ti 2 The mixed solution of C nanosheets was placed in a polytetrafluoroethylene tank, heated to 300°C, sealed for 15 hours, and filtered to obtain nanostructured Ti 2 C microspheres;

[0044] (4) The nanostructured Ti obtained in step (3) 2 C microspheres were dried at 90°C for 20 hours, and Ti 2 C microspheres.

[0045] After testing, nano-microstructure lithium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com