Preparation method of three-dimensional porous vanadium phosphate sodium / carbon anode material

A sodium vanadium phosphate, three-dimensional porous technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of unpredictability of renewable energy, haze invasion of ecology, environmental pollution, etc., and achieve capacity utilization and rate performance. Less than ideal, the effect of improving reversible capacity and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 182mg (1mmol) V 2 o 5 , was added to 30 mL of deionized water, and then 2 mL of H 2 o 2 Let it dissolve. Next, weigh 294mg (1mmol) sodium citrate (Na 3 C 6 h 5 o 7 2H 2 O), 345 mg (3 mmol) NH 4 h 2 PO 4 and 136.8mg citric acid (C 6 h 8 o 7 ) into the above solution, and after it was completely dissolved, it was poured into a stainless steel reactor lined with polytetrafluoroethylene, and reacted at 180°C for 6 hours. After the reaction was completed, the gel precursor was taken out and dried for 12 hours. Finally, the dry gel precursor was calcined at 750° C. for 8 h in a mixed gas of argon-hydrogen (5%) to obtain a three-dimensional porous sodium vanadium phosphate / carbon composite positive electrode material. The argon-hydrogen (5%) The mixed gas means that the volume fraction of hydrogen in the mixed gas is 5vol.%.

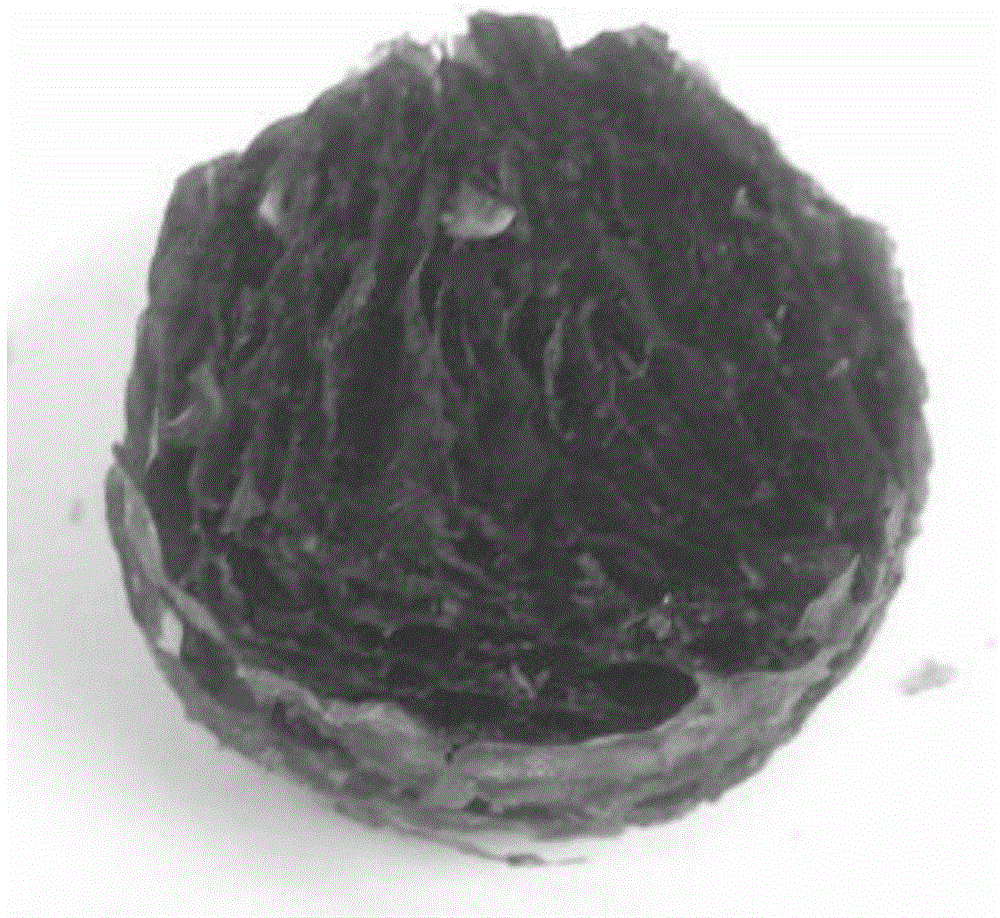

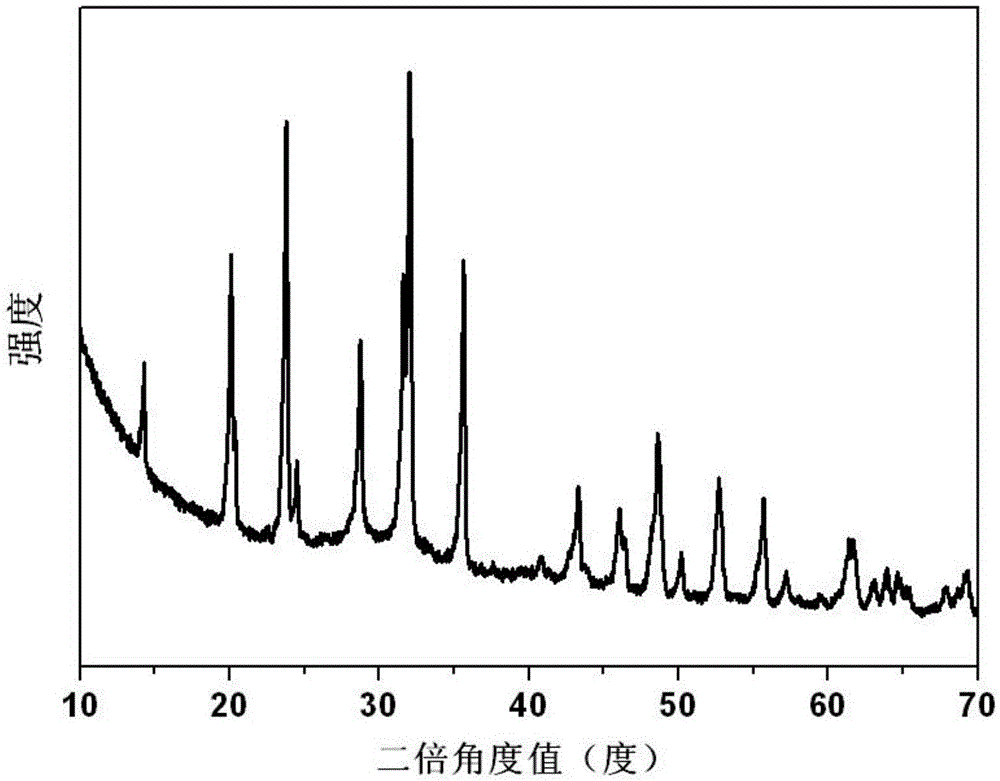

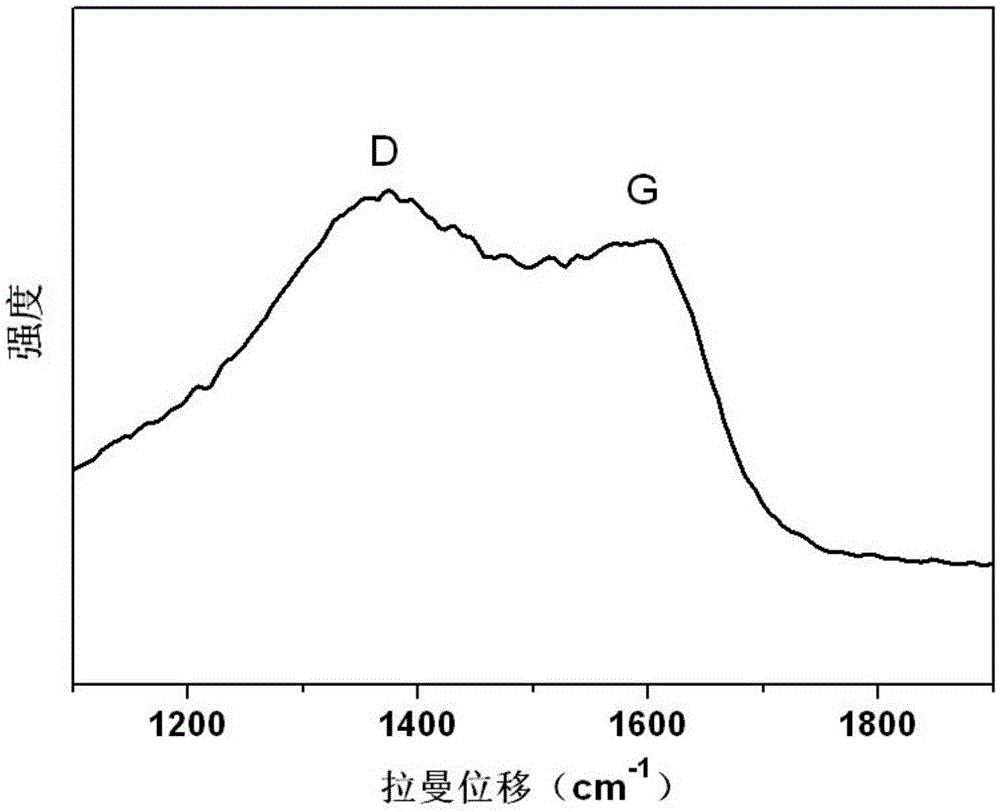

[0026] figure 1 It is a three-dimensional physical photo of the product obtained in Example 1, and the pore structure can be clea...

Embodiment 2

[0033] Weigh 234mg (2mmol) ammonium metavanadate (NH 4 VO 3 ), added to 50mL deionized water, and then added 5mL H 2 o 2 Let it dissolve. Next, weigh 246mg (3mmol) sodium acetate (CH 3 COONa), 294mg (3mmol) H 3 PO 4 and 228mg of polyvinylpyrrolidone were added to the above solution, and after it was completely dissolved, it was poured into a stainless steel reactor lined with polytetrafluoroethylene, and reacted at 220°C for 2h. After the reaction was completed, the gel precursor was taken out and dried for 12 hours. Finally, the dry gel precursor was calcined at 750° C. for 8 h in a mixed gas of argon-hydrogen (5%) to obtain a three-dimensional porous sodium vanadium phosphate / carbon composite cathode material.

Embodiment 3

[0035] Weigh 150mg (1mmol) V 2 o 3, was added to 10 mL of deionized water, and then 1 mL of H 2 o 2 Let it dissolve. Next, weigh 201mg (1.5mmol) sodium oxalate (Na2C 2 o 4 ), 609mg (3mmol) ammonium phosphate ((NH 4 ) 3 PO 4 ) and 45.6 mg of polyethylene glycol 400 were added to the above solution, and after it was completely dissolved, it was poured into a stainless steel reactor lined with polytetrafluoroethylene, and reacted at 140 ° C for 12 hours. After the reaction was completed, the gel precursor was taken out and dried for 12 hours. Finally, the dry gel precursor was calcined at 750° C. for 8 h in a mixed gas of argon-hydrogen (5%) to obtain a three-dimensional porous sodium vanadium phosphate / carbon composite cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com