Material with mixture of ions with sodium vanadium phosphate cathode material coated by carbon and preparing method thereof

A technology of carbon-coated sodium vanadium phosphate and positive electrode materials, which is applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of affecting electrochemical performance, small ion diffusion rate, and poor electronic conductivity, etc. Effects of electrical conductivity, uniformity of carbon layer, and improvement of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

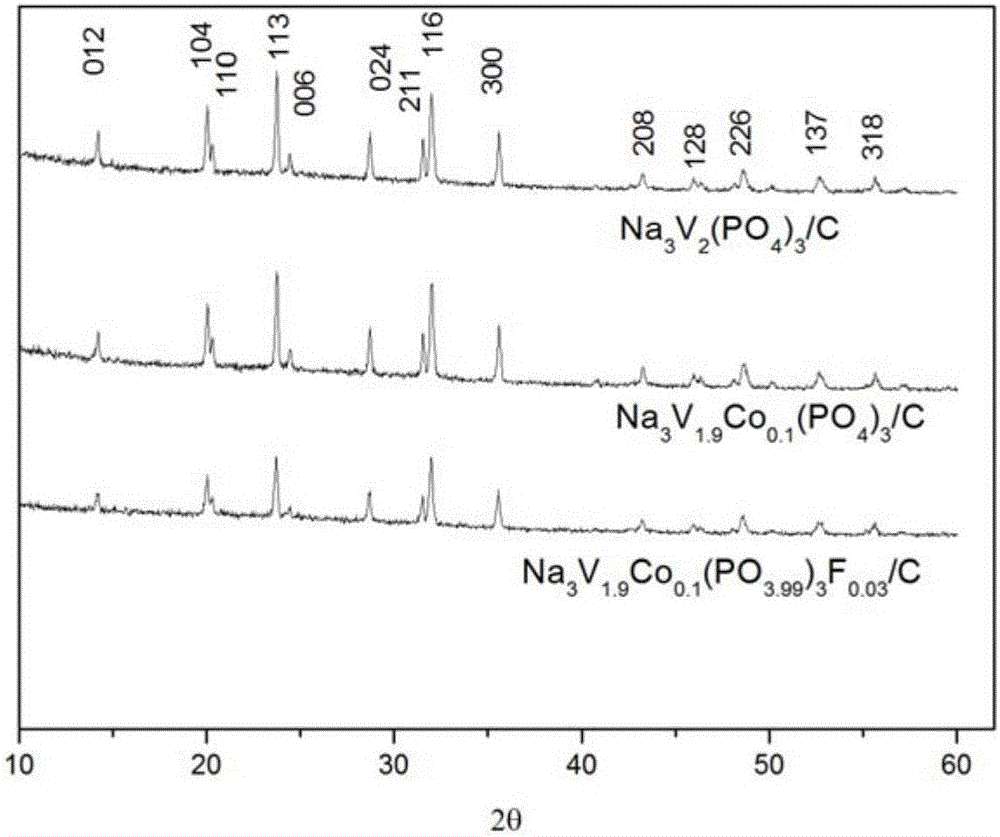

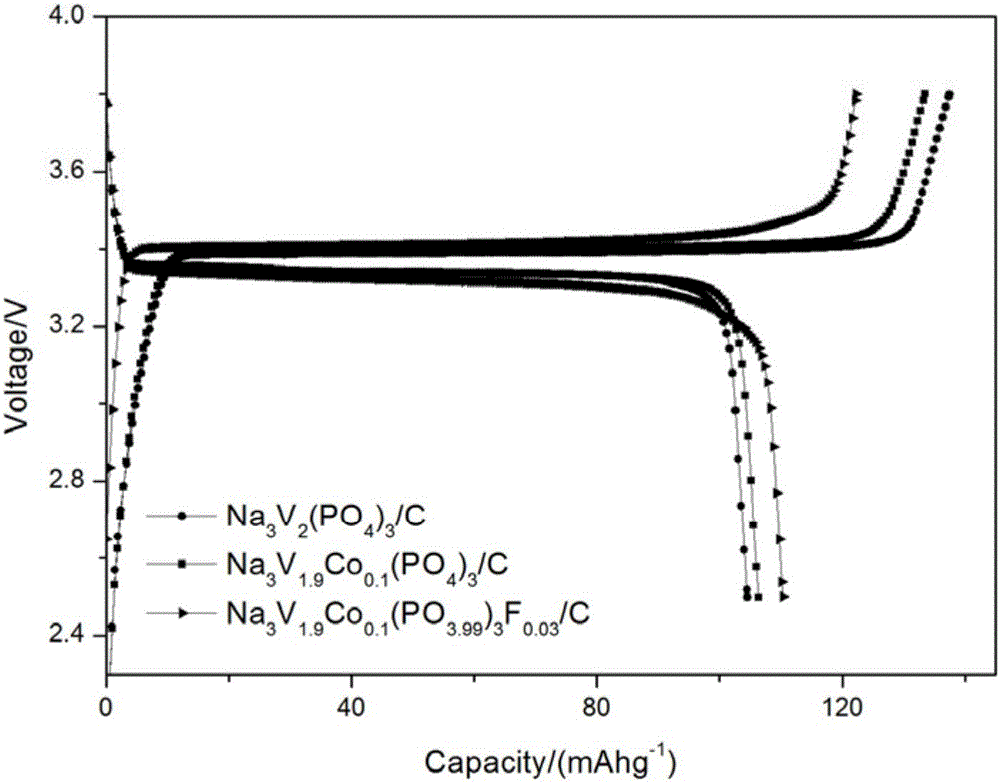

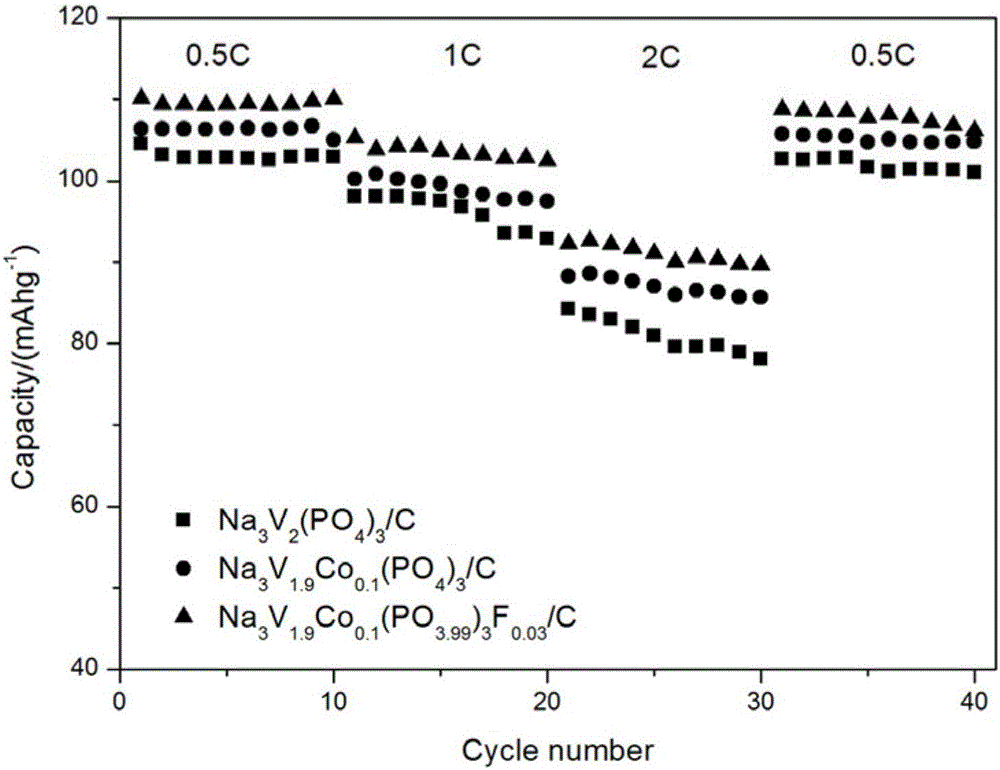

[0025] The present embodiment prepares sodium vanadium phosphate cathode material Na according to the following steps 3 V 2 (PO 4 ) 3 / C:

[0026] (1) Take by weighing 0.3975g of sodium carbonate, 0.5849g of ammonium metavanadate, 0.8627g of ammonium dihydrogen phosphate, and 1.0507g of citric acid according to the molar ratio of Na:V:P:C=3:2:3:2;

[0027] (2) Mix citric acid and ammonium metavanadate, add 200mL deionized water, stir and heat in a water bath at 80°C for 1 hour to form a mixed solution; then mix sodium carbonate and ammonium dihydrogen phosphate in deionized water, Drop by drop into the mixture, continue to stir and heat for 4 hours to form a gel; dry the gel in vacuum and grind to obtain a mixed powder;

[0028] (3) Heat the mixed powder in a tube furnace filled with nitrogen at a rate of 2min / °C to 350°C for 4 hours, take out the obtained product and grind it evenly again; The temperature was raised to 850° C. and kept for 8 hours to obtain the carbon-co...

Embodiment 2

[0034] This embodiment prepares cobalt-doped carbon-coated sodium vanadium phosphate positive electrode material Na according to the following steps 3 V 1.9 co 0.1 (PO 4 ) 3 / C:

[0035] (1) Weigh 0.3975g of sodium carbonate, 0.5557g of ammonium metavanadate, 0.0728g of cobalt nitrate, and 0.8627g of ammonium dihydrogen phosphate according to the molar ratio of Na:V:Co:P:C=3:1.9:0.1:3:2 g, citric acid 1.0507g;

[0036] (2) Mix citric acid, ammonium metavanadate and cobalt nitrate, add 200mL deionized water, stir and heat in a water bath at 80°C for 1 hour to form a mixed solution; then mix sodium carbonate and ammonium dihydrogen phosphate in deionized After soaking in water, drop it into the mixed solution drop by drop, continue to stir and heat for 4 hours to form a gel; dry the gel in vacuum and grind it to obtain a mixed powder;

[0037] (3) Heat the mixed powder in a tube furnace filled with nitrogen at a rate of 2min / °C to 350°C for 4 hours, take out the obtained p...

Embodiment 3

[0043] In this example, cobalt-fluorine co-doped carbon-coated sodium vanadium phosphate cathode material Na 3 V 1.9 co 0.1 (PO 3.99 ) 3 f 0.03 / C:

[0044] (1) Weigh sodium carbonate 0.3935g, ammonium metavanadate 0.5557g, cobalt nitrate 0.0728g, phosphoric acid according to the molar ratio of Na:V:Co:P:F:C=3:1.90:0.1:3:0.03:2 Dihydroammonia 0.8627g, sodium fluoride 0.0031g, citric acid 1.0507g;

[0045] (2) Mix citric acid, ammonium metavanadate, cobalt nitrate and sodium fluoride, add 200mL deionized water, stir and heat in a water bath at 80°C for 1 hour to form a mixed solution; then mix sodium carbonate and ammonium dihydrogen phosphate After dissolving in deionized water, drop it into the mixed solution drop by drop, continue stirring and heating for 4 hours to form a gel; dry the gel in vacuum, grind it to obtain a mixed powder;

[0046] (3) Heat the mixed powder in a tube furnace filled with nitrogen at a rate of 2min / °C to 350°C for 4 hours, take out the obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com