Modified silane surface pretreating agent containing polyoxyethylene octadecanol ether and preparation method of modified silane surface pretreating agent

A technology of stearyl polyoxyethylene ether and treatment agent, which is applied in the field of modified silylated surface pretreatment agent and its preparation, and can solve the problems of self-healing problems such as lack of "self-repairing" performance, weak corrosion resistance "Poor performance and other problems, to achieve the effect of no hanging dust, strong corrosion resistance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

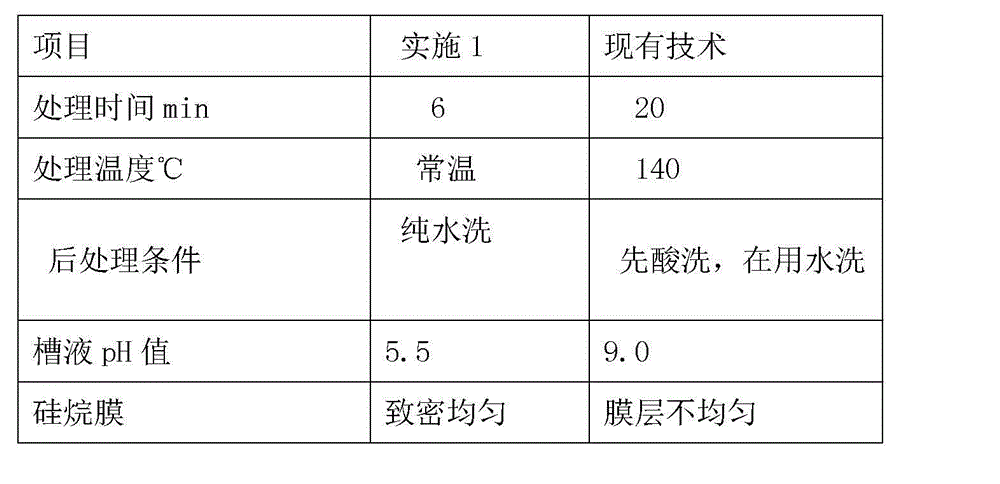

Examples

Embodiment 1

[0022] Weigh raw materials according to the following weight (kg): 100 deionized water, 13 modified coupling agents, 14 ethanol, 702 35 silane coupling agents, 25 silane coupling agents KH-550, 1.5 dicumyl peroxide, and perfluorooctanoic acid Sodium 0.0025, tree ash 0.4, acrylic emulsion 5, stearyl polyoxyethylene ether 0.9, lanthanum acetate 0.05, phytic acid 0.25,

[0023] Preparation:

[0024] (1) Preparation of modified coupling agent

[0025] Add water-soluble nano-scale silica sol to 4.5% nano-zinc powder, 4% iron oxide, and 5% 2-aminoethylheptadecenyl imidazoline, mix and heat to 100°C, and cool after 25 minutes;

[0026] (2) First add silane coupling agent 702 in the mixing tank according to the formula ratio, then add dicumyl peroxide, stir at 200-300rpm for 3-4 minutes, then add silane coupling agent KH-550 , after stirring at a speed of 300-400rpm for 3-5 minutes, adding sodium perfluorooctanoate and tree ash, stirring at a speed of 350-450rpm for 30-40 minutes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com