Corrosive liquid for preparing monocrystal silicon textured surface and method thereof

A technology of etching liquid and monocrystalline silicon, which is applied in the field of solar cells, can solve the problems of easy-to-break production cost, large thickness of monocrystalline silicon, and high cost of isopropanol, and achieve the effects of cost saving, stable properties, and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

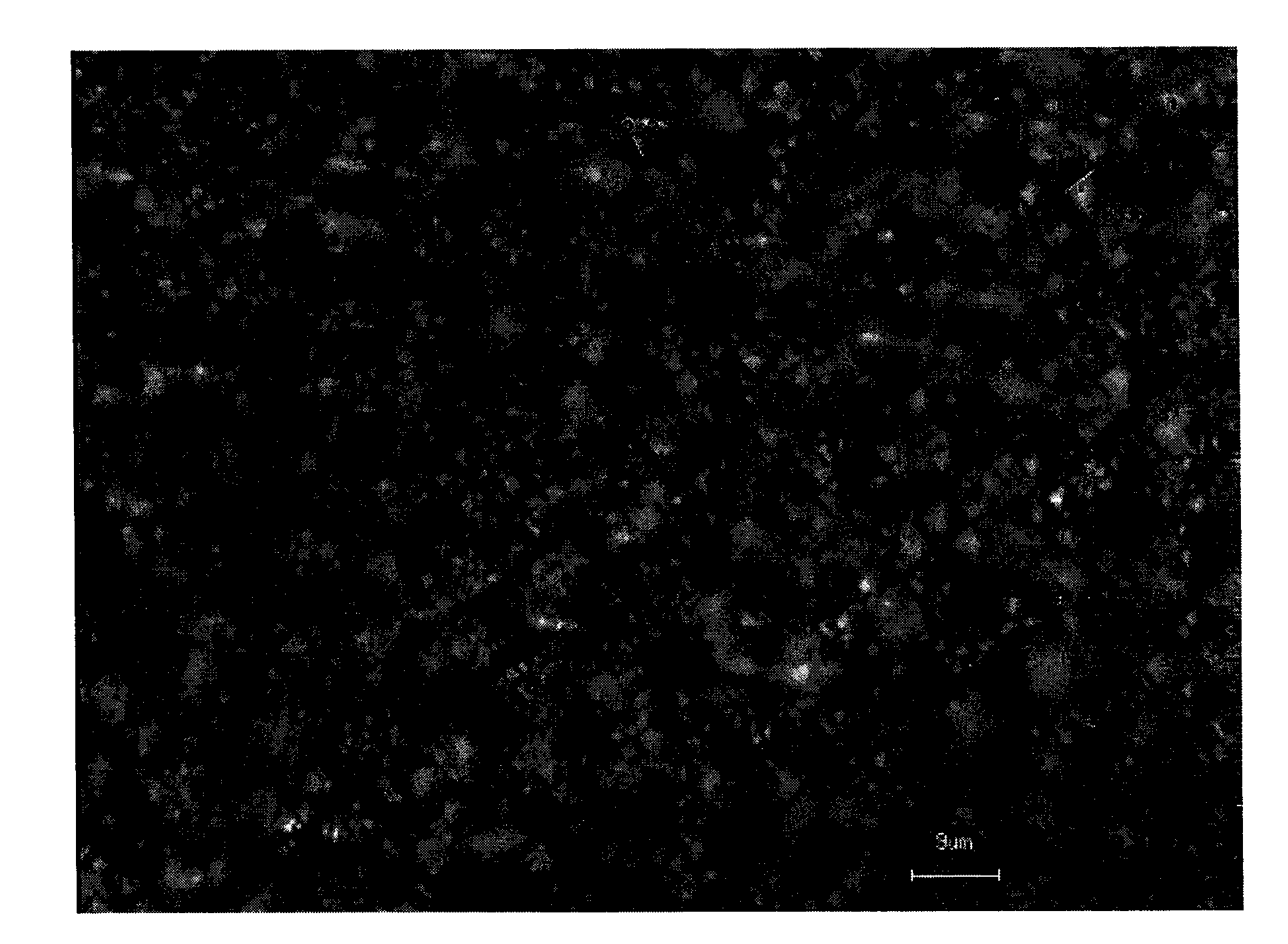

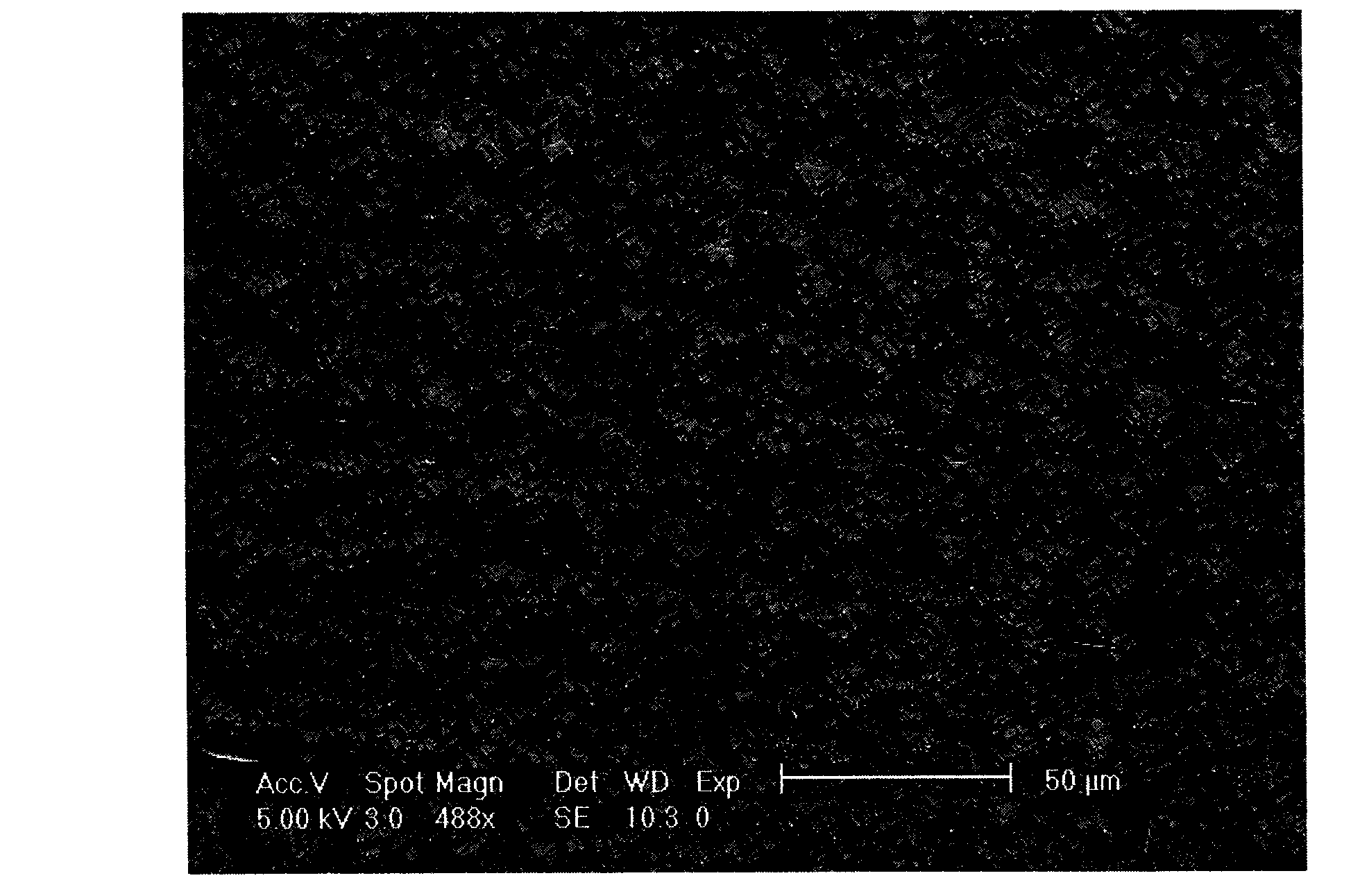

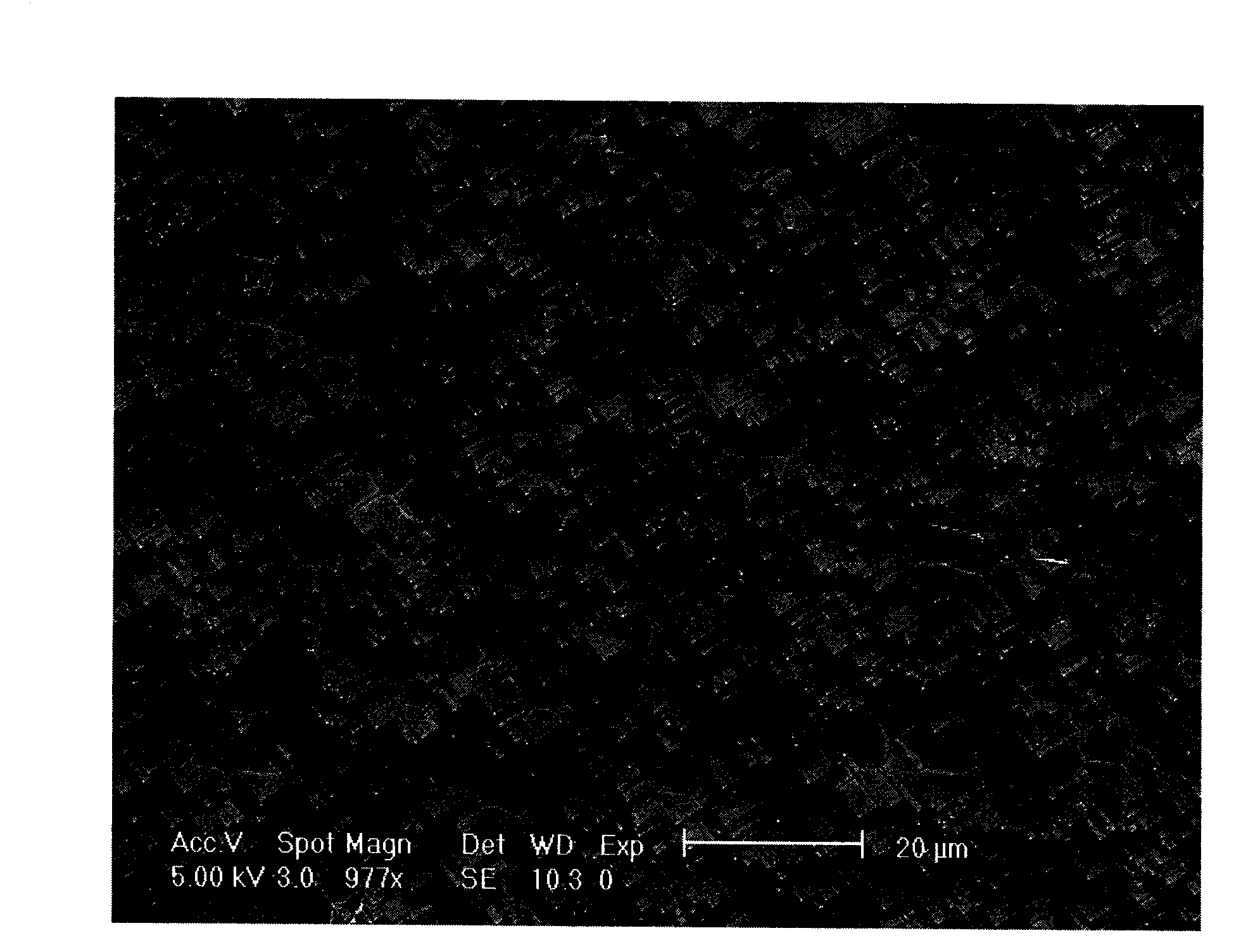

[0020] Such as Figure 1~3 as shown, Figure 1~3 Be that the temperature of constant temperature bath is 75 ℃, alkaline solution is 1.5 (% by mass percent) sodium hydroxide, 0.12 (% by volume percent) sodium silicate, 0.5 (volume percent) isopropanol, 0.5 (volume percent) concentration is 5*10 -5 ~5*10 -3 The perfluorooctanoate aqueous solution of mol / L, and when corrosion time is 18min, the obtained monocrystalline silicon with pyramid texture, under the microscope observes on the surface of single crystal silicon to form uniform pyramid texture (such as figure 1 shown), and the side length of the pyramid is 0.5-8 μm (such as figure 2 , image 3 shown), the etched thickness on the single crystal silicon is 10 μm.

Embodiment 2

[0022] When the temperature of the constant temperature bath is 85°C, the alkali solution is 1.5 (% mass) sodium hydroxide, 0.12 (% mass) sodium silicate, 0.5 (volume %) isopropanol, and the concentration of 0.5 (% volume) is 5*10 -5 ~5*10 -3 mol / L perfluorooctanoate aqueous solution, and when the etching time is 7 minutes, the side length of the pyramid on the obtained monocrystalline silicon textured surface is 0.5-8 μm, and the etched thickness of the monocrystalline silicon is 10 μm.

[0023] The perfluorooctanoate used in the present invention is an anionic neutral surfactant, which has very high thermodynamic and chemical stability, and can stably and effectively exert its surface activity in special application systems such as strong acid, strong alkali, and strong oxidizing medium It will not react or decompose with the system; PFOA also has good compatibility and can be widely used in various PH value ranges, various water-based and solvent-based systems, and can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com