Sludge-based activated carbon with effect of efficiently adsorbing PFOS (perfluorooctane sulfonate) and PFOA (perfluorooctanoic acid) and preparation method as well as application of sludge-based activated carbon

A technology of activated carbon and sludge, which is applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that sludge-based activated carbon is rarely used, and achieve good adsorption and removal effects , low cost, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1.1 Preparation of sludge-based activated carbon

[0033] The undigested dewatered sludge of the municipal sewage treatment plant was vacuum dried at 105°C to a moisture content of 10%, and then passed through a 160-mesh sieve after grinding; then the sludge was immersed in 0.5 mol / L ZnCl 2 In the solution, activate at 40°C for 24 hours. The activated sample is centrifuged and dried; the dried sludge sample is carbonized in a muffle furnace at 600°C for 45 minutes, and the obtained crude sample is repeatedly washed with water 3 times. Dry to constant weight; immerse the crude sample in 3mol / L hydrochloric acid for 1 hour, cool to room temperature, repeatedly wash with water to neutral, and dry at 60°C to constant weight to obtain sludge-based activated carbon.

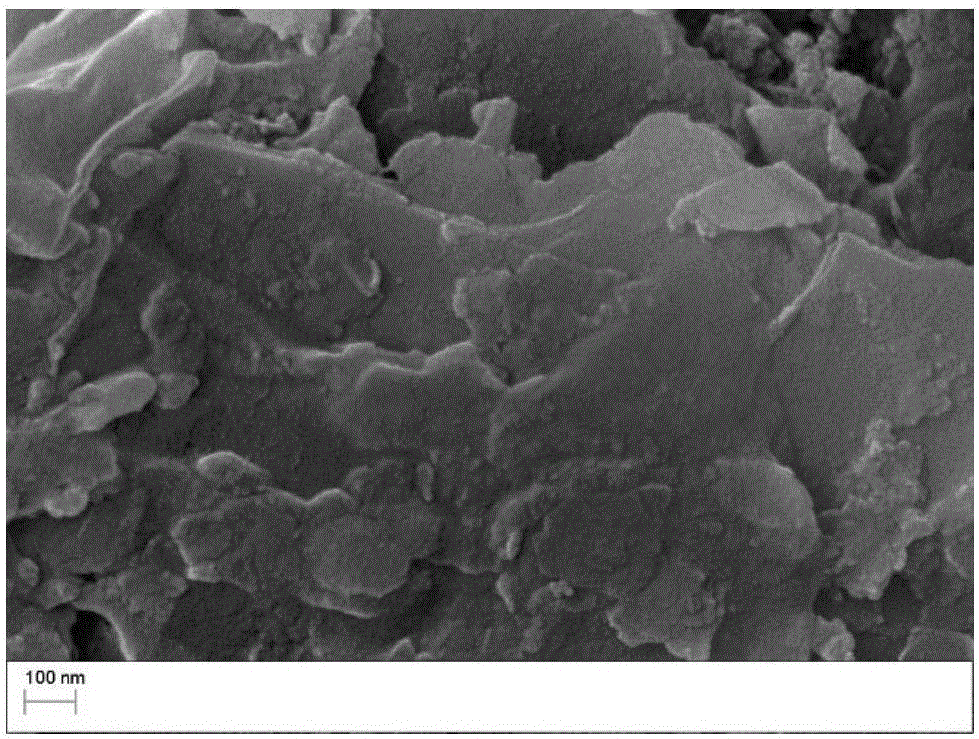

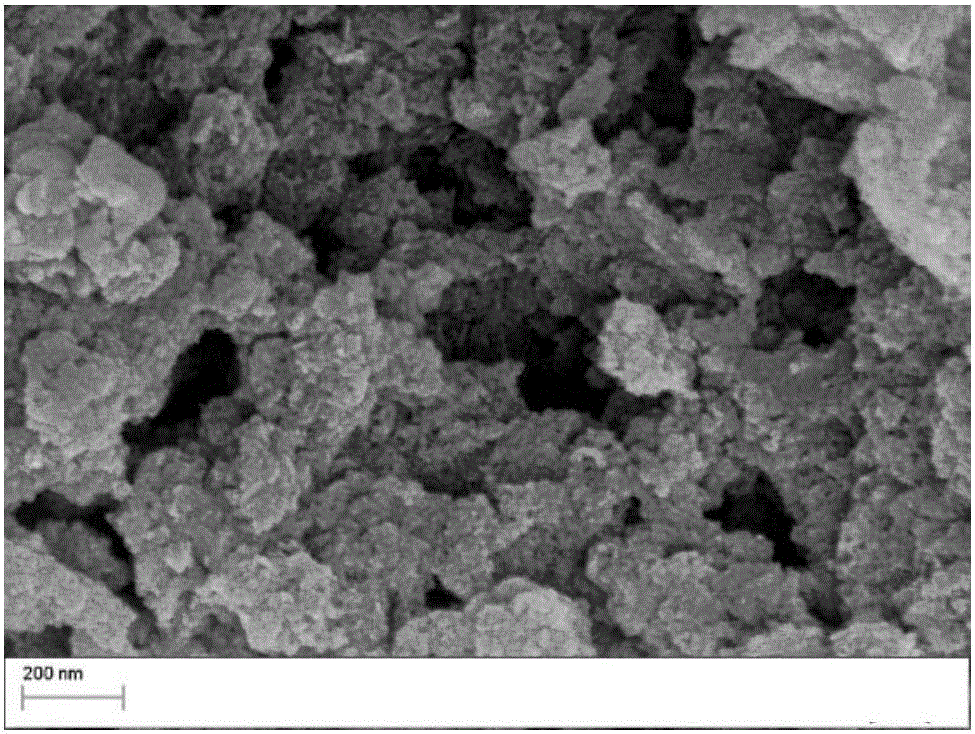

[0034] From Figure 1a It can be clearly seen that the original sludge has a dense surface and an underdeveloped pore structure. After being prepared into activated carbon, it has more pores, fine and uniform pore dist...

Embodiment 2

[0039] The steps are the same as in Example 1, except that during the preparation of sludge-based activated carbon, the sludge is immersed in 0.1 mol / L ZnCl 2 The solution was activated at 30°C for 12h, and the activated sample was centrifuged and dried; the dried sludge sample was carbonized in a muffle furnace at 700°C for 2h to obtain sludge-based activated carbon.

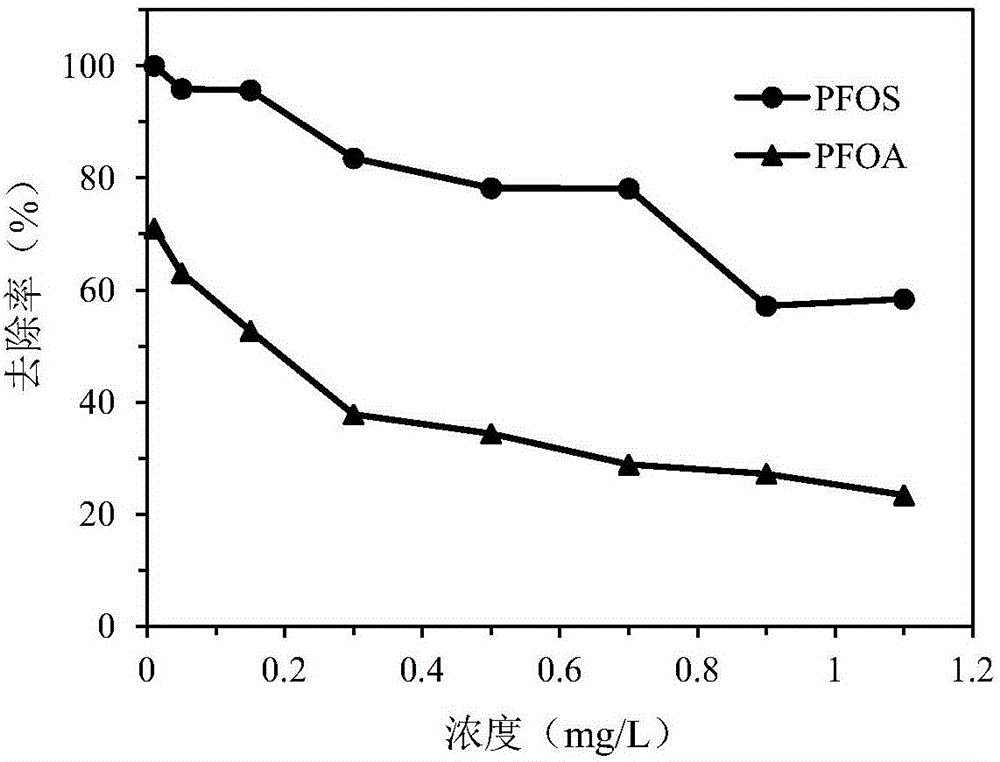

[0040] The steps are the same as in Example 1. During the adsorption process, the temperature is 25°C, the pH is 3, the constant-temperature oscillation speed is 160 rpm, the concentration of PFOS and PFOA in the adsorption reaction system are both 0.5 mg / L, and the sludge-based activated carbon is used for adsorption The addition amount of the agent in the adsorption reaction system is 10mg / L, the final PFOS removal rate is 94.9%, and the PFOA removal rate is 54.3%.

Embodiment 3

[0042] The steps are the same as in Example 1, except that during the preparation of sludge-based activated carbon, the sludge is immersed in 0.25 mol / L of ZnCl 2 The solution was activated at 50°C for 18h, and the activated sample was centrifuged and dried; the dried sludge sample was carbonized in a muffle furnace at 800°C for 1.5h to prepare sludge-based activated carbon.

[0043] The steps are the same as in Example 1, except that during the adsorption process, the temperature is 25°C, the pH is 6, the constant-temperature oscillation speed is 160 rpm, and the sample is sampled after 12 hours of oscillation. The concentration of PFOS and PFOA in the adsorption reaction system are both 0.5 mg / L. The addition amount of base activated carbon used as adsorbent in the adsorption reaction system is 50mg / L, the final PFOS removal rate is 99.5%, and the PFOA removal rate is 82.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com