Preparation method of liquid carbon dioxide thickening agent

A technology of liquid carbon dioxide and thickening agent, applied in the preparation of liquid carbon dioxide thickening agent, in the field of anhydrous fracturing fluid, can solve the problems of reservoir damage, affecting fracturing stimulation, reducing reservoir permeability, etc., to increase the viscosity , the effect of improving the dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

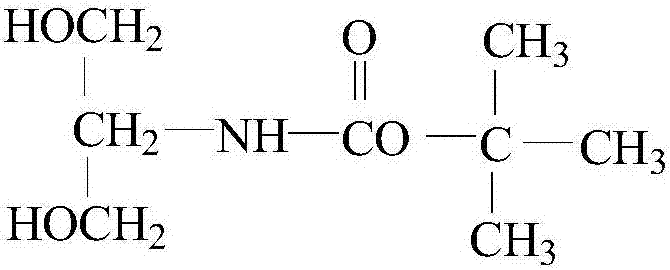

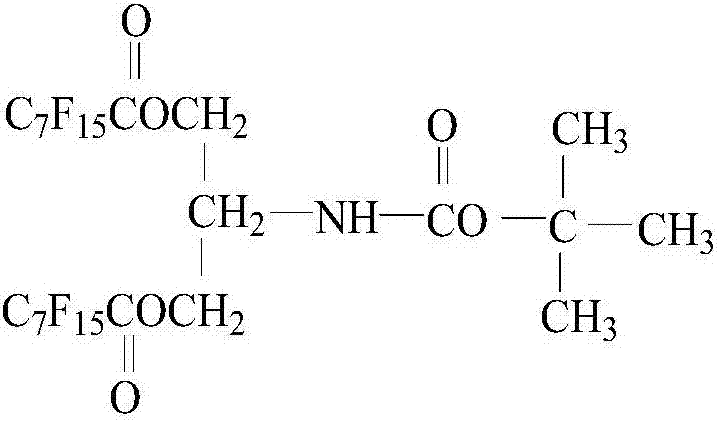

[0022] (1) Preparation of 1,3-dihydroxypropane-2-carbamic acid tert-butyl ester

[0023] Add 6mL of deionized water and 14mL of methanol into the three-necked flask, stir and mix evenly, then add 0.02mol of serinol into the mixed solution, stir to dissolve completely, cool down to 0°C with an ice bath, and then add the three to the mixed solution Slowly add 0.022mol of di-tert-butyl dicarbonate dropwise. During the dropping process, the temperature was kept at 0°C. After 30 minutes, the ice bath was removed, and the reaction was carried out at a constant temperature of 25°C for 4 hours. After the reaction was completed, it was extracted three times with dichloromethane. The solvent methanol and water were distilled off under reduced pressure, and vacuum-dried at 45° C. for 24 hours to obtain the product tert-butyl 1,3-dihydroxypropane-2-carbamate.

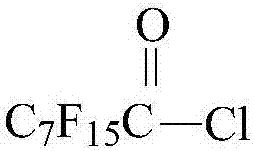

[0024] (2) Preparation of perfluorooctanoyl chloride

[0025] Add 0.02mol of perfluorooctanoic acid into another three-necked fl...

Embodiment 2

[0032] (1) Preparation of 1,3-dihydroxypropane-2-carbamic acid tert-butyl ester

[0033] Add 6mL of deionized water and 14mL of methanol into the three-necked flask, stir to dissolve completely, and cool down to 0°C with an ice bath, then slowly add 0.021mol of di-tert-butyl dicarbonate dropwise to the mixed solution of the three, during the dropwise addition , the temperature was kept at 0°C, and after 30 minutes, the ice bath was removed, and the reaction was carried out at a constant temperature of 25°C for 4 hours. After the reaction was completed, extracted three times with dichloromethane, the solvent methanol and water were distilled off under reduced pressure, and dried under vacuum at 45°C After 24h, the product tert-butyl 1,3-dihydroxypropane-2-carbamate was obtained.

[0034] (2) Preparation of perfluorooctanoyl chloride

[0035] Add 0.02mol of perfluorooctanoic acid into another three-necked flask equipped with a condenser, raise the temperature to 75°C, then add ...

Embodiment 3

[0042] (1) Preparation of 1,3-dihydroxypropane-2-carbamic acid tert-butyl ester

[0043] Add 6mL of deionized water and 14mL of methanol into the three-necked flask, stir and mix evenly, take 0.02mol of serinol and add it into the mixed solution, stir to dissolve completely, cool down to 0°C with an ice bath, and then slowly add to the mixed solution of the three. Add 0.023mol of di-tert-butyl dicarbonate dropwise. During the dropwise addition, the temperature was kept at 0°C. After 30 minutes, the ice bath was removed, and the reaction was carried out at a constant temperature of 25°C for 4 hours. The solvent methanol and water were distilled off under pressure, and vacuum-dried at 45°C for 24 hours to obtain the intermediate product 1,3-dihydroxypropane-2-carbamate tert-butyl ester.

[0044] (2) Preparation of perfluorooctanoyl chloride

[0045] Take 0.02mol of perfluorooctanoic acid and add it into another three-necked flask equipped with a condenser, raise the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com