Oil-water separation material with pH responsiveness and multi-stage structure and preparation method of oil-water separation material

An oil-water separation and responsive technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of cumbersome preparation methods, complex synthesis of polymer P, complex surface roughness operation, etc., and achieve simple synthesis steps, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

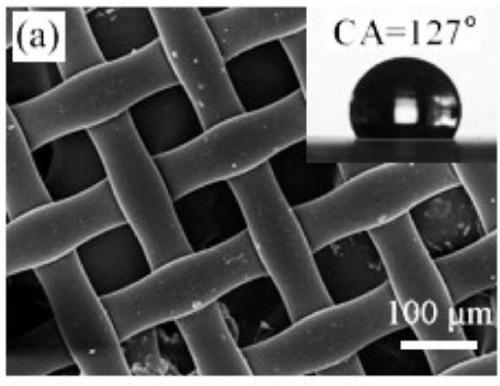

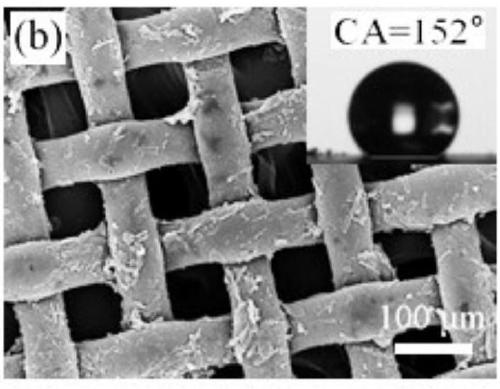

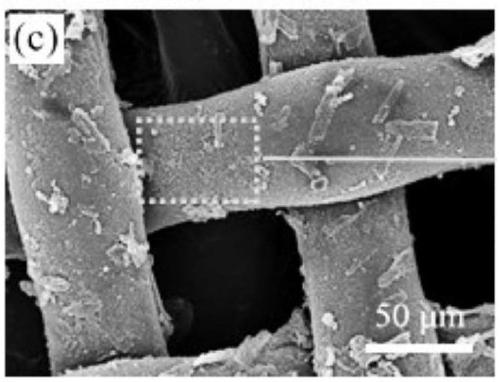

[0040] Weigh 1.61g of perfluorooctanoic acid (PFOA) into a 100mL beaker, add 30mL of deionized water to it, measure 1mL of aniline monomer and add it to the above PFOA solution, then place it in a constant temperature water bath at 25°C and stir for 30min to make it evenly mixed . Cut a 3cm×3cm polyester screen, wash it repeatedly with ethanol and deionized water, dry it, and then immerse it in the above mixed solution for 10 minutes. Weigh 2.74g of ammonium persulfate (APS) and dissolve it in 30mL of deionized water, ultrasonically shake until completely dissolved, and add the APS solution drop by drop into the beaker at a constant speed while keeping stirring. When the APS was added, the stirring was continued for 5 min, and then the stirring was stopped. The whole system was left to react for 24 hours in a constant temperature water bath at 25°C. After the reaction, the polyaniline / polyester mesh composite material was washed with absolute ethanol until it was colorless a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com