Preparation method of porous nanometer crystal electrodes and application of porous nanometer crystal electrodes

A technology of electrodes and nanocrystals, applied in the field of electrochemistry, to achieve the effects of convenient operation, good treatment effect and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

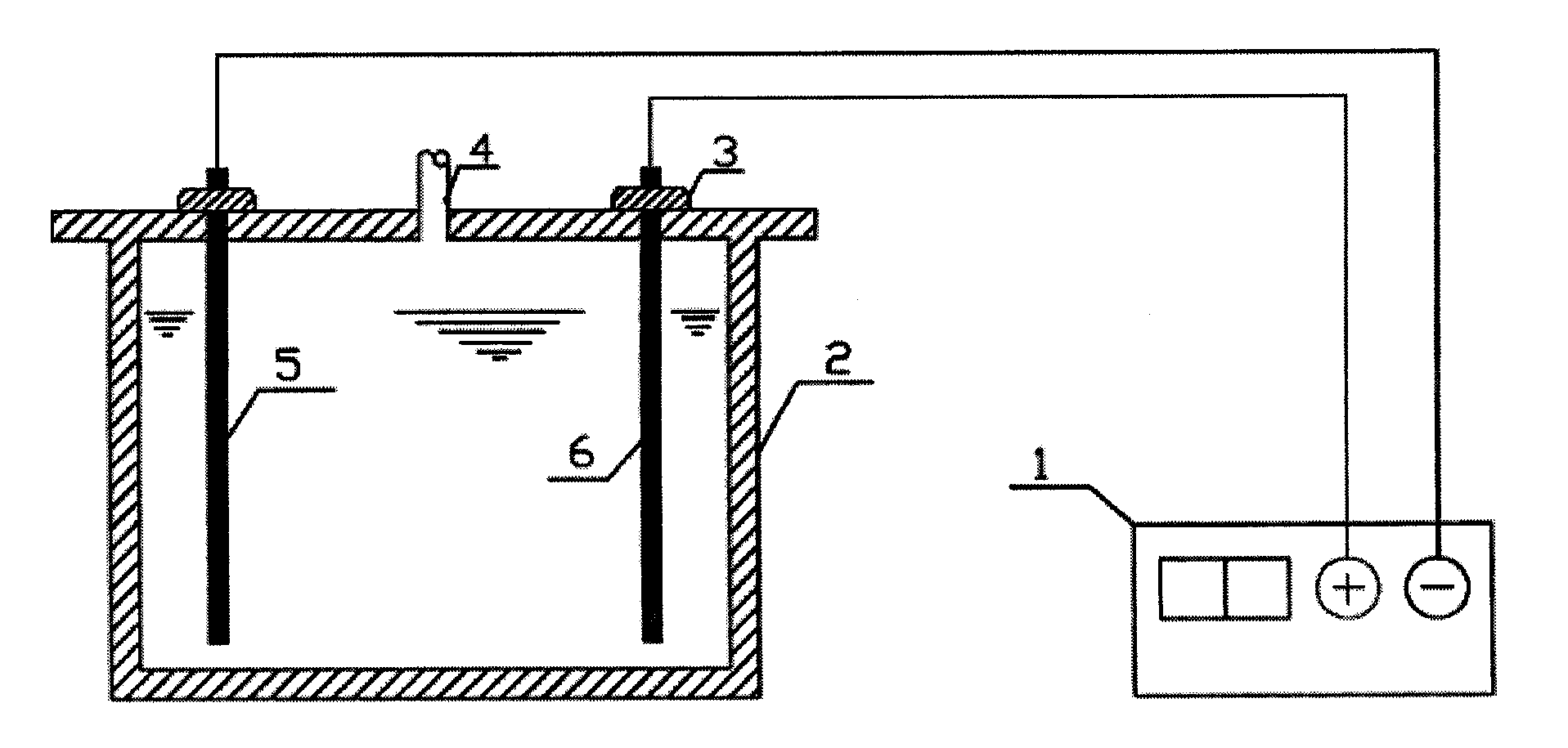

[0016] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

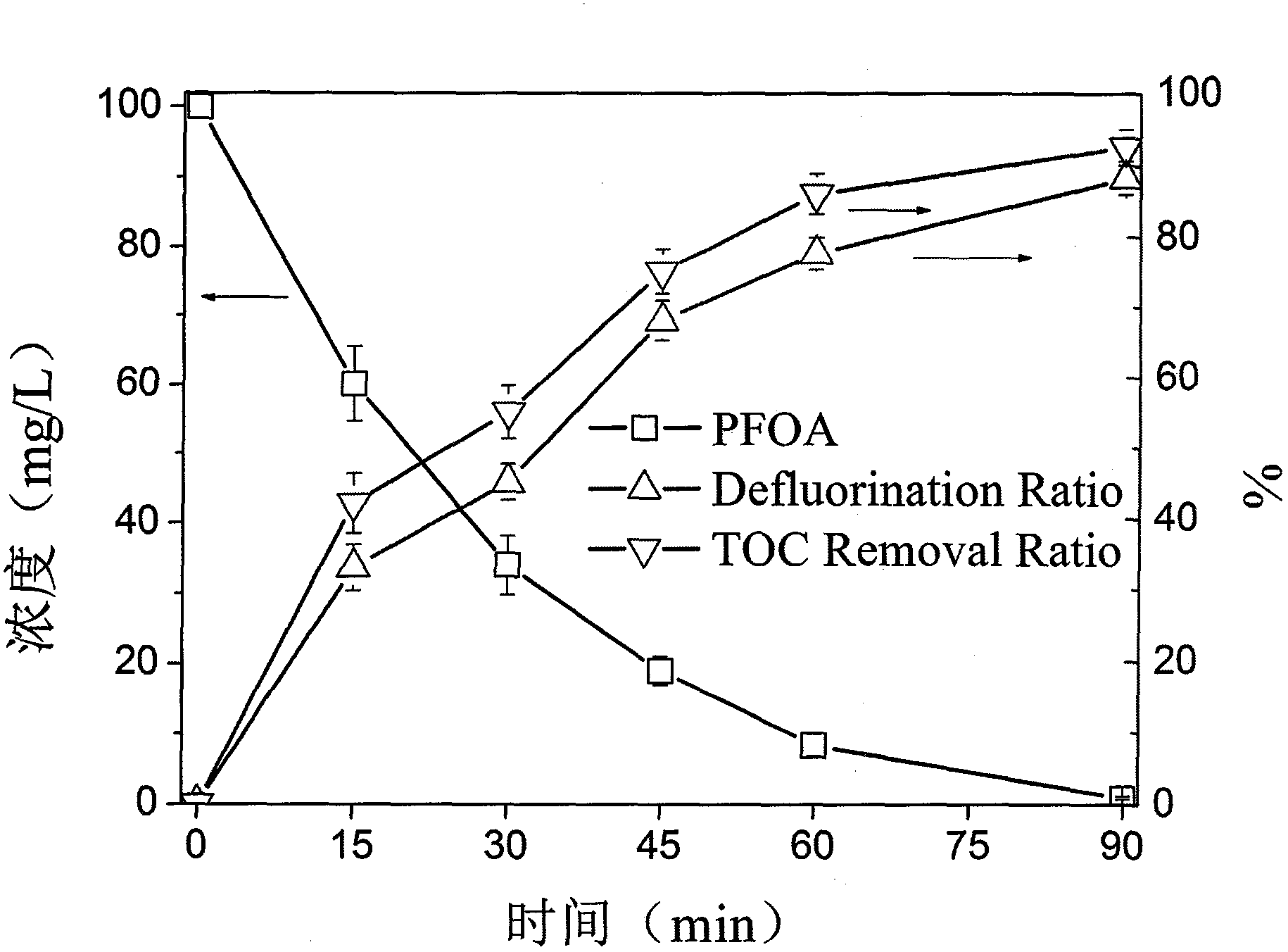

[0017] A method for electrochemically oxidizing and efficiently mineralizing perfluorooctanoic acid in water according to the present invention, and its preferred specific implementation method includes steps:

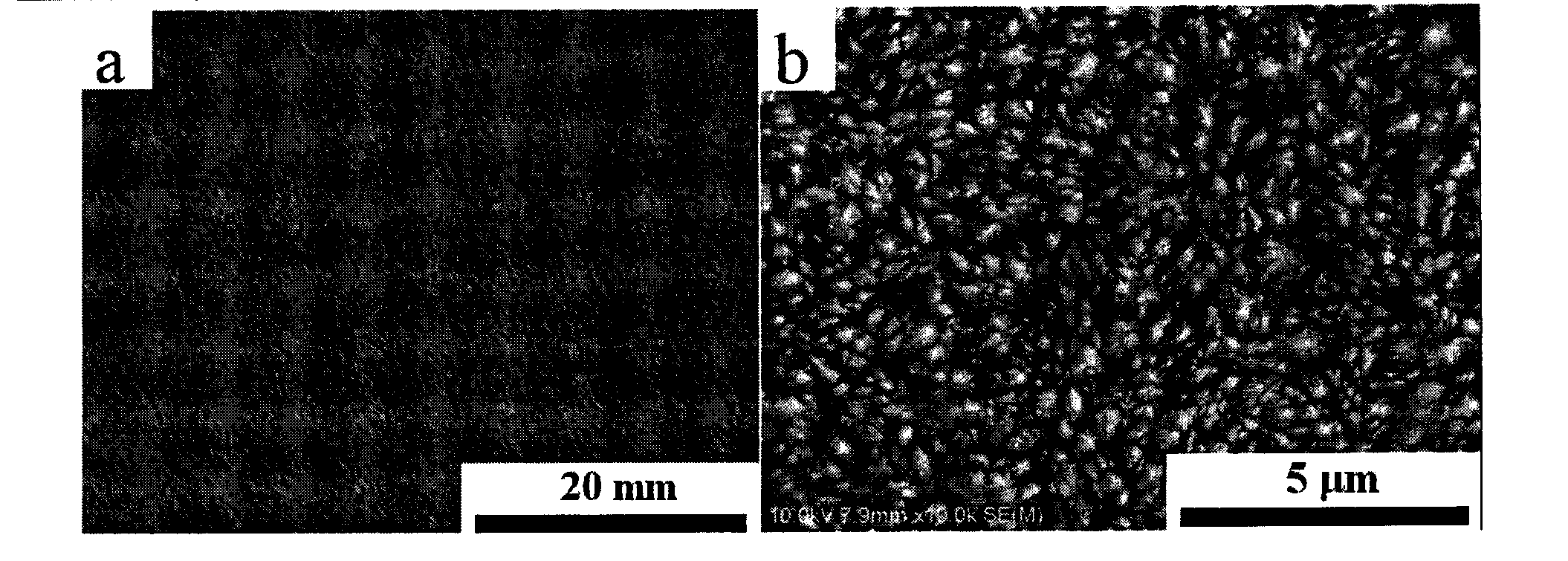

[0018] Porous nanocrystalline Ti / SnO 2 -Sn / Ce-PbO 2 Electrode preparation:

[0019] ① First, polish the Ti substrate with 200-mesh sandpaper, then immerse it in 8% sodium hydroxide solution at 100°C for 1 hour, take it out and wash it with distilled water, and then etch it in 10% oxalic acid solution at 100°C for 2.5 hours;

[0020] ② Dissolve a certain amount of citric acid in ethylene glycol at a temperature of 60°C, keep the temperature for 30 minutes after complete dissolution, then heat to 90°C, add SnCl 4 ·5H 2 O and SbCl 3 , stir well until the dissolution is complete, then raise the temperature to 100°C and keep the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com