Preparation method of fluorine-containing polymer

A technology for polymers and fluorine-containing olefins, which is applied in the field of preparation of fluorine-containing polymers, and can solve problems such as high risk, affecting the polymerization process and polymer performance, and high risk in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

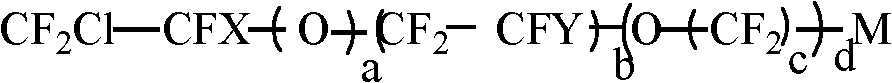

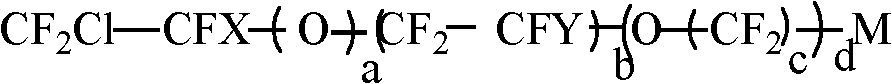

Image

Examples

Embodiment 1

[0023] Taking a 5L polymerization kettle as an example, add 2.97L deionized deoxygenated water, 3g fluorine-containing surfactant CF 2 ClCFClOCF 2 CF(CF 3 )OCF 2 CF 2 SO 3 NH 4 , and then vacuumize and remove oxygen until the oxygen content in the polymerization tank is ≤ 20ppm, which is qualified. Use tetrafluoroethylene monomer to increase the pressure of the polymerization tank to 2.0MPa. After the temperature of the polymerization tank rises to 75°C, add the concentration of 30ml of 10% ammonium persulfate aqueous solution, start the polymerization reaction, keep the temperature at 75°C, and keep the pressure at 2.0MPa. After 12 hours of reaction, stop adding monomer, and when the pressure drops to 0.5MPa, recover unreacted tetrafluoroethylene . Agglomerated, washed, and dried to obtain 670 g of polytetrafluoroethylene solid powder.

Embodiment 2

[0025] Taking a 5L polymerization kettle as an example, add 2.9L deionized deoxygenated water, 0.3g fluorine-containing surfactant ClCF 2 (CF 2 ) 5 OCF 2 CF 2 SO 3 K, then vacuumize and remove oxygen until the oxygen content in the polymerization tank is ≤ 20ppm, it is qualified, use vinylidene fluoride monomer to increase the pressure of the polymerization tank to 6.0MPa, and when the temperature of the polymerization tank rises to 45°C, add 15g Diisopropyl peroxydicarbonate, start the polymerization reaction, keep the temperature at 45°C, and add vinylidene fluoride monomer in time according to the polymerization reaction process, so that the pressure in the kettle is kept at 6.0MPa, and stop after 10 hours of reaction Add monomer, when the pressure drops to 0.5MPa, recover unreacted vinylidene fluoride. Agglomerated, washed, and dried to obtain 600 g of polyvinylidene fluoride solid powder.

Embodiment 3

[0027] Take a 5L polymerization kettle as an example, add 3L deionized deoxygenated water, 15g fluorine-containing surfactant CF 2 ClCFClOCF 2 CF(CF 3 )OCF 2 COONa, 100g perfluoropropyl vinyl ether, and then vacuumize and remove oxygen until the oxygen content in the polymerization kettle is ≤ 20ppm, which is qualified. Use tetrafluoroethylene monomer to boost the pressure of the polymerization kettle to 1.0MPa, and wait for the temperature of the polymerization kettle to rise. After reaching 25°C, use a metering pump to add 30g bisperfluoroacyl peroxide to start the polymerization reaction, keep the temperature at 25°C, and keep the pressure at 1.0MPa. After 15 hours of reaction, stop feeding and recover unreacted tetrafluoroethylene and perfluoropropyl vinyl ether. Agglomerated, washed, and dried to obtain 550 g of modified polytetrafluoroethylene solid powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com