Phosphate silkete penetrating agent and preparation method thereof

A mercerizing penetrant, phosphoric acid ester technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of light alkali influence, inorganic phosphoric acid pipeline corrosion, worker injury, etc., and achieve the effect of good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation process of the mercerized penetrant of the present invention is mainly to first add a certain amount of deionized water to the fatty alcohol and the fatty alcohol polyoxyethylene ether, raise the temperature to 50-80°C, and add the phosphorylation reagent under uniform stirring. , heat up to 100-120°C, keep warm, carry out esterification reaction for 2-4 hours, then add organic acid anhydride into the three-necked flask, continue to keep warm, carry out esterification reaction for 2-4 hours, then add deionized water, and hydrolyze for 2-4 hours , after cooling sufficiently, the target mercerizing penetrant product can be obtained.

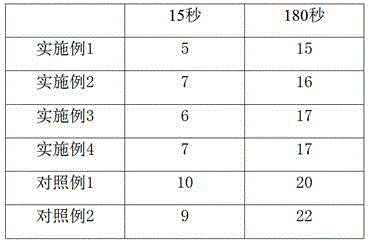

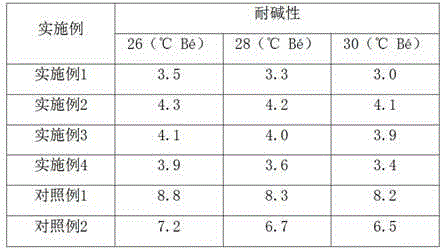

[0031] The amount of the mercerizing penetrant provided by the present invention in the alkali solution in the mercerizing process can be 0.05-5%, or 0.1-2%, or 0.1-1%. The content of sodium hydroxide in the alkaline solution can be used in a conventional amount without any particular limitation, for example, it can be 100-35...

Embodiment 1

[0034] Weigh the mixed fatty alcohol (30g of isotridecanol + 20g of polyethylene glycol).

[0035] Weigh 10 g of fatty alcohol polyoxyethylene ether isotridecyl alcohol ether (EO6). The fatty alcohol polyoxyethylene ether contains isomeric tridecyl alcohol ether, isomeric decanol ether, or a mixture of one or both of them.

[0036] Put fatty alcohol and fatty alcohol polyoxyethylene ether in a three-necked flask, add 10g of deionized water at the same time to start stirring, raise the temperature to 70°C, and add 15g of phosphorus pentoxide while stirring evenly, and turn on the condenser to reflux. Heat up to 110°C, keep it warm for 3 hours, then add 15g of maleic anhydride to the three-neck flask and continue to keep it warm for 3 hours, then add 10g of deionized water, hydrolyze for 3 hours, and the target mercerized penetrant product will be obtained after cooling sufficiently.

Embodiment 2

[0038] Difference with embodiment 1 is that raw material is different:

[0039] Composition of mixed fatty alcohols: 20 g of isomeric decanol, 15 g of polypropylene glycol;

[0040] Fatty alcohol polyoxyethylene ether: isomeric tridecyl ether 15 g;

[0041] Phosphorus pentoxide 15 g;

[0042]Maleic anhydride 15 g;

[0043] Deionized water: 10g and 5g are added in the first and second additions respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com