Preparation method of glass fiber/carbon nanotube/epoxy resin multi-dimensional hybrid composite material

A carbon nanotube and glass fiber technology, applied in the field of nanomaterials, can solve the problems of high surface energy of carbon nanotubes, difficult to achieve uniform dispersion, easy to agglomerate, etc., to improve the lack of interlayer shear strength, and the preparation method is simple and easy. Line and interface bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

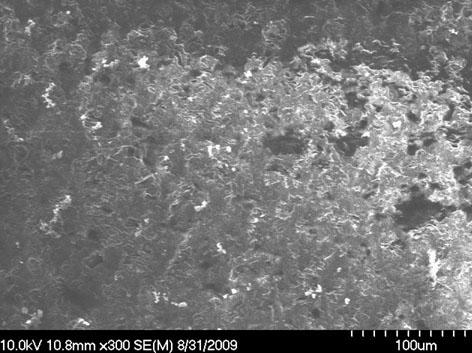

[0032] Example 1: Multi-walled carbon nanotubes (OD<8nm) and glass fibers prepared by an arc discharge method are used as initial raw materials. After purification of the multi-walled carbon nanotubes, the glass fibers are treated with a silane coupling agent, and the carbon nanotubes are After acidification, acyl chlorination, amination, and pyromellitic dianhydride acid anhydride, the carbon nanotubes and liquid bisphenol A epoxy resin (E-51) are chemically cross-linked, and the surface bonded The multi-walled carbon nanotubes of liquid bisphenol A epoxy resin are combined with the glass fiber treated with silane coupling agent KH550 in a certain way to obtain a multi-dimensional hybrid composite material containing glass fiber / carbon nanotube / epoxy resin.

[0033] Step (1): In a 250mL single-neck round bottom flask equipped with a stirrer, add 1.1g of dried multi-walled carbon nanotube raw material and 100mL, 20% nitric acid solution, treat it under 120kHz ultrasonic wave fo...

Embodiment 2

[0042] Example 2: Single-walled carbon nanotubes (OD<8nm) prepared by chemical vapor deposition were used as the initial raw material, the single-walled carbon nanotubes were purified, the glass fibers were treated with a silane coupling agent, and the carbon nanotubes were acidified, Acyl chlorination, amination, and anhydride with benzophenone tetraacid dianhydride, chemical cross-linking reaction between carbon nanotubes and liquid bisphenol A epoxy resin (E-54), and liquid bisphenol on the surface can be obtained. Single-walled carbon nanotubes of type A epoxy resin (E-54), and then composite them with glass fibers treated with silane coupling agent KH560 in a certain way to obtain multidimensional hybrid composites containing glass fibers / carbon nanotubes / epoxy resin Material

[0043] Step (1): In a 500mL single-neck round bottom flask equipped with a stirrer, add 1.1g of dried single-walled carbon nanotube raw material and 100mL, 20% weight concentration of sulfuric acid...

Embodiment 3

[0051] Example 3: The single-walled carbon nanotubes (OD, - After the anhydride of diphenylmethane is anhydrided, the carbon nanotubes are chemically cross-linked with the liquid bisphenol A epoxy resin (E-44), and the surface is connected with the liquid bisphenol A epoxy resin (E-44). -44) single-walled carbon nanotubes, and then compound them with glass fibers treated with silane coupling agent KH570 in a certain way to obtain a multidimensional hybrid composite material containing glass fibers / carbon nanotubes / epoxy resin.

[0052] Step (1): in the 500mL single-necked round bottom flask that has been equipped with stirrer, add 10g through the dry single-walled carbon nanotube raw material and the sulfuric acid of 250mL, 20% weight concentration, process 80 hours under 120kHz ultrasonic wave, then Heat and stir at 180°C and reflux, react for 48 hours, filter with ψ0.8μm polytetrafluoroethylene microfiltration membrane, wash with deionized water 3-10 times until neutral, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com