Machinable solid buoyancy material and preparation method thereof

A solid buoyancy, epoxy curing agent technology, used in the field of functional non-metallic materials, can solve the problem that the material cannot meet the requirements of underwater engineering and permanent buoys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

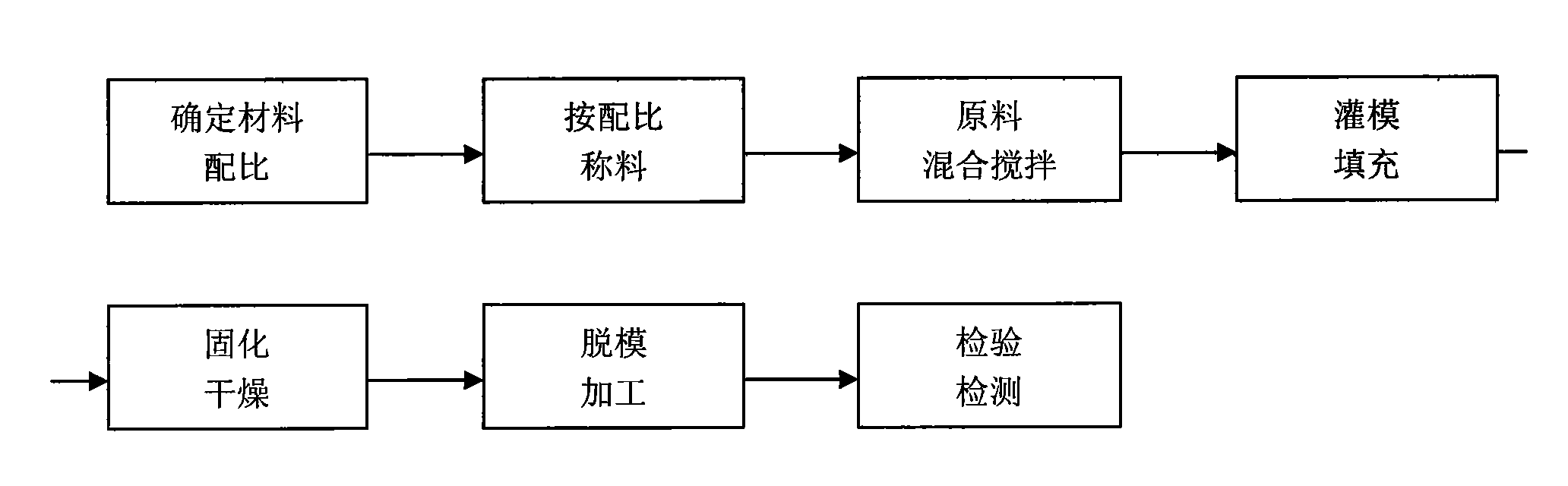

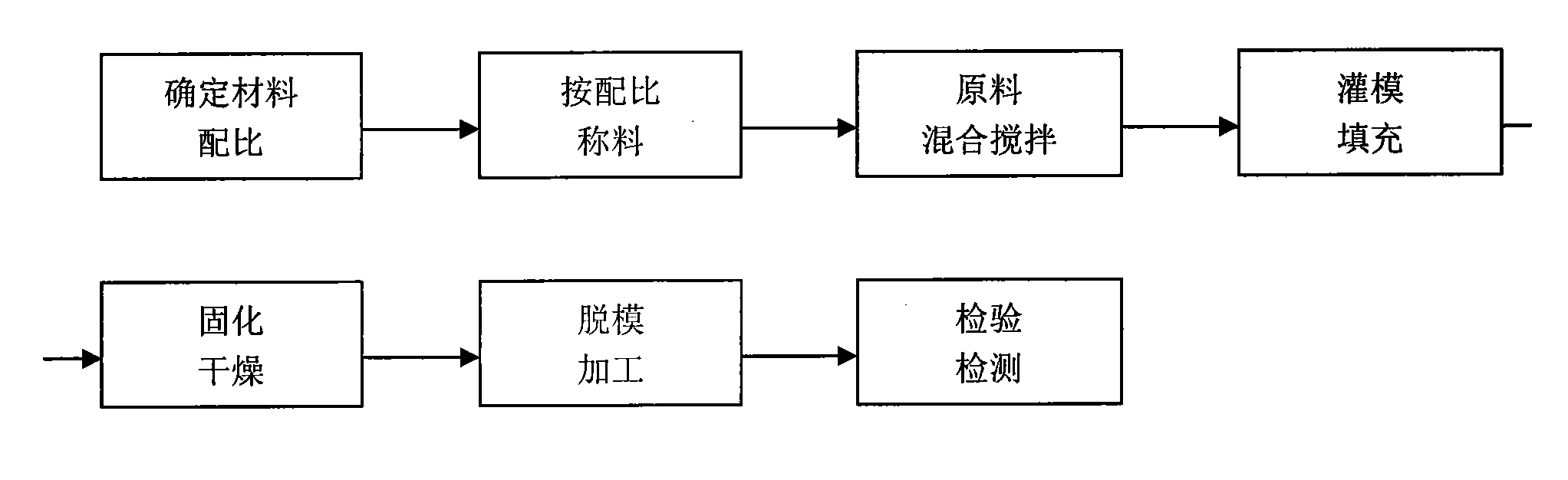

Method used

Image

Examples

Embodiment 1

[0026] 1) Heat bisphenol S-type epoxy resin and polyamide 650 curing agent in a water bath at a temperature of 50°C;

[0027] 2) Take bisphenol S type epoxy resin, polyamide 650 curing agent and K15 glass microspheres by weighing respectively;

[0028] 3) Add the weighed bisphenol S type epoxy resin and polyamide 650 curing agent into the mixer, stir, and make it mix evenly;

[0029] 4) Add K15 glass microspheres in the mixer and stir to make it mix evenly;

[0030] 5) Take out the material in the mixer and add it to the kneading machine for kneading, the time is 10 minutes;

[0031] 6) After kneading the material, put the material into the material bucket or table;

[0032] 7) Cut the release wax paper according to the size of the mold, coat the inner wall of the mold with a release agent, and paste the release paper (plastic side outward);

[0033] 8) Tightly pour or fill the material on the bucket or table into the mold covered with release wax paper, use vacuum and vibr...

Embodiment 2

[0037] 1) Heat bisphenol S epoxy resin and triethanolamine curing agent in a water bath at a temperature of 60°C;

[0038] 2) Take bisphenol S type epoxy resin, triethanolamine curing agent and K20 glass microspheres respectively by weighing;

[0039] 3) Add the bisphenol S type epoxy resin and triethanolamine curing agent weighed in the mixer, stir, and make it mix evenly;

[0040] 4) Add K20 glass microspheres in the blender and stir to make it evenly mixed;

[0041] 5) Take out the material in the mixer and add it to the kneading machine for kneading, the time is 8 minutes;

[0042] 6) After kneading the material, put the material into the material bucket or table;

[0043] 7) Cut the release wax paper according to the size of the mold, coat the inner wall of the mold with a release agent, and paste the release paper (plastic side outward);

[0044] 8) Tightly pour or fill the material on the bucket or table into the mold covered with release wax paper, if necessary, use...

Embodiment 3

[0048] 1) Heat glycidyl epoxy resin and polyamide 651 curing agent in a water bath to 55°C;

[0049] 2) Weighing glycidyl epoxy resin, polyamide 651 curing agent and S38 glass microspheres respectively;

[0050] 3) Add the weighed glycidyl epoxy resin and polyamide 651 curing agent into the mixer, stir, and make it mix evenly;

[0051] 4) Add S38 glass beads into the mixer and stir to make it evenly mixed;

[0052] 5) Take out the material in the mixer and add it to the kneading machine for kneading, the time is 10 minutes;

[0053] 6) After kneading the material, put the material into the material bucket or table;

[0054] 7) Cut the release wax paper according to the size of the mold, coat the inner wall of the mold with a release agent, and paste the release paper (plastic side outward);

[0055] 8) Tightly pour or fill the material on the bucket or table into the mold covered with release wax paper, if necessary, use a vacuum or vibrating machine to fill it; cover the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com