Catalyst component for polymerization of ethylene, catalyst and preparation method of catalyst component

A technology for ethylene polymerization and catalysts, which is applied in the field of catalyst components for ethylene polymerization, and can solve problems such as the inability to prepare N-type polyolefin catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Preparation of catalyst components

[0059] Add 4.0 g of magnesium chloride, 100 ml of toluene, 9.0 ml of epichlorohydrin, and 15.0 ml of tri-n-butyl phosphate into the reaction kettle, and react for 2 hours at a stirring speed of 450 rpm and a temperature of 60°C, and add 3 g of phthalate Formic anhydride, 2ml butyl acetate and 1ml cyclobutanone, keep the temperature constant for 1 hour, cool down to -40°C, add 70ml of titanium tetrachloride dropwise, gradually raise the temperature to 95°C, keep the temperature for 1 hour, filter off the mother liquor, pass through an inert diluent Washing with toluene and organic solvent hexane several times and then drying to obtain a solid containing magnesium / titanium.

[0060] (2) Polymerization reaction

[0061] A stainless steel reaction kettle with a volume of 2L, after being fully replaced by high-purity nitrogen, add 1L of hexane and 1.0ml of triethylaluminum with a concentration of 1M, and then add the solid catalyst c...

Embodiment 2

[0064] (1) Preparation of catalyst components

[0065] Add 4.0 grams of magnesium chloride, 105ml of toluene, 7.0ml of epichlorohydrin, and 11ml of triisobutyl phosphate into the reaction kettle, and react for 2 hours at a stirring speed of 450rpm and a temperature of 60°C, and add 2g of phthalo Acid anhydride, 1ml butyl acetate and 1ml cyclopentanone, continue to keep the temperature for 1 hour, cool down to -40°C, add 75ml of titanium tetrachloride dropwise, gradually raise the temperature to 95°C, keep the temperature for 1 hour, filter off the mother liquor, pass through the inert diluent toluene and the organic solvent hexane for several times and then dried to obtain a magnesium / titanium-containing solid.

[0066] (2) Polymerization reaction: with embodiment 1, polymerization result is shown in Table 1.

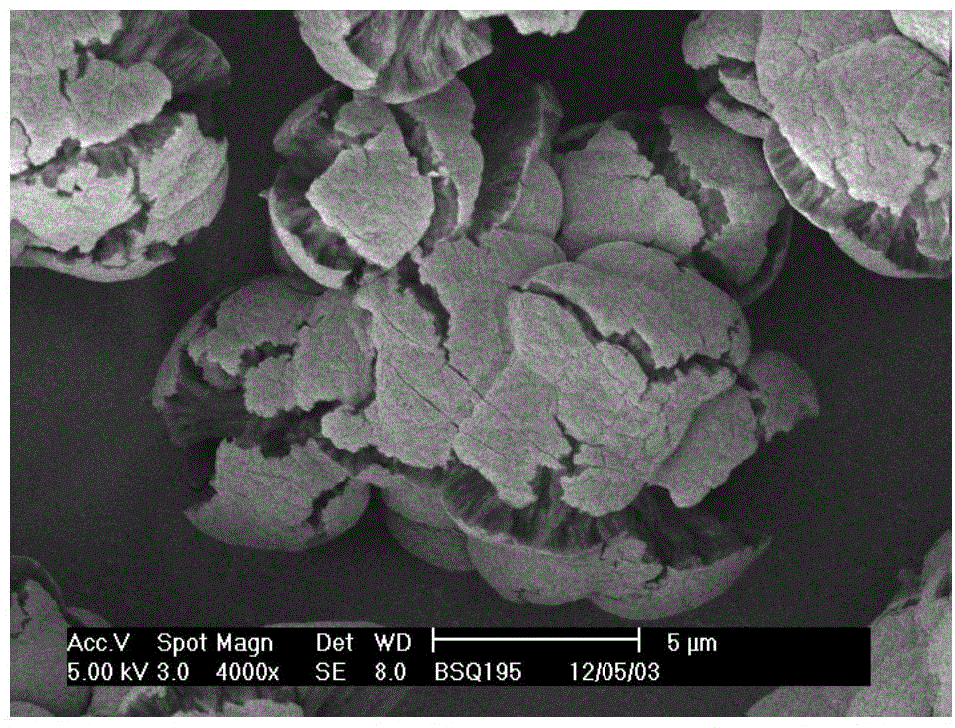

[0067] (3) Electron microscope photo: See Figure 4 for the electron micrograph of the catalyst.

Embodiment 3

[0069] (1) Preparation of catalyst components

[0070] Add 4.0 grams of magnesium chloride, 100ml of toluene, 9ml of epichlorohydrin, and 10ml of triisobutyl phosphate into the reaction kettle, and react for 2 hours at a stirring speed of 350rpm and a temperature of 60°C, and add 2g of phthalic anhydride , 1ml of n-octyl acetate and 1ml of cyclohexanone, continue to keep the temperature for 1 hour, cool down to -40°C, add 30ml of titanium tetrachloride dropwise, gradually raise the temperature to 95°C, keep the temperature for 1 hour, filter off the mother liquor, and pass through the inert diluent toluene and the organic solvent hexane for several times and then dried to obtain a magnesium / titanium-containing solid.

[0071] (2) Polymerization reaction: with embodiment 1, polymerization result is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com