Method and device for blast furnace coal gas fine desulfurization and purification

A blast furnace gas and gas refining technology, which is applied in the preparation/purification of sulfur, removal of gas pollutants, catalytic conversion of impurities, gas purification, etc., can solve the problems of difficult desulfurization, unrecovered sulfur elements, poor adsorption and desulfurization effects, etc. problems, achieve the effect of reducing desulfurization investment cost and operating cost, improving adsorption desulfurization efficiency, and improving desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

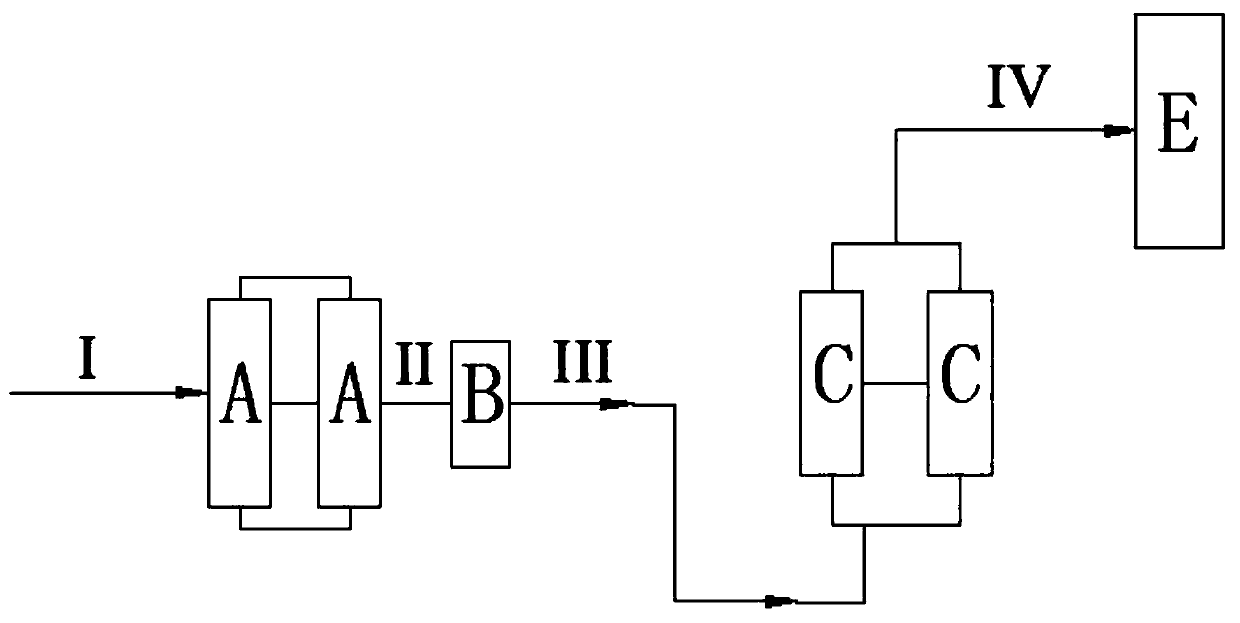

Embodiment 1

[0048] The total sulfur concentration in the blast furnace gas I is between 250mg / m3, enters the conversion unit, converts the organic sulfur in the stream I into hydrogen sulfide to form the stream II, and the conversion unit contains a potassium-modified alumina catalyst; the stream II enters the cooling Unit to form stream III; stream III enters the adsorption unit composed of at least two adsorption towers connected in parallel to remove hydrogen sulfide from blast furnace gas to form clean gas stream IV. The total sulfur content of stream IV is 20mg / Nm3, and the adsorption tower contains copper modified Molecular sieve adsorption material; at least two adsorption towers in the adsorption unit are used in parallel, and the towers are switched automatically to ensure that at least one tower absorbs sulfide, and the other adsorption tower with saturated adsorption is decomposed and regenerated under the action of high-temperature clean gas, high-temperature clean gas The sulf...

Embodiment 2

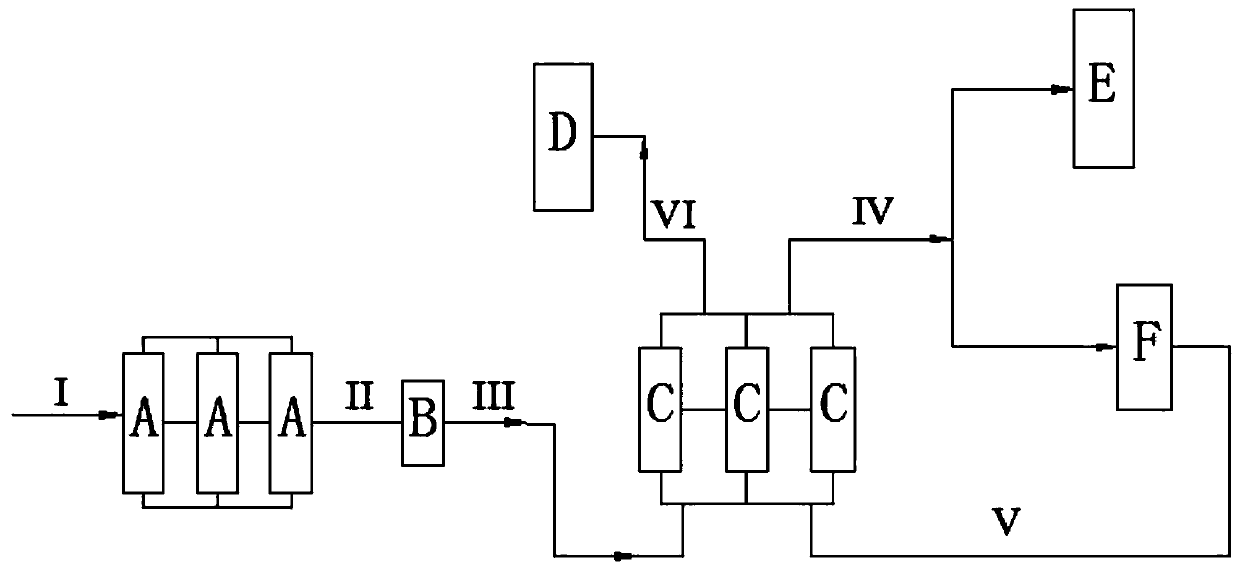

[0050] The total sulfur concentration in the blast furnace gas I is between 200mg / m3, enters the conversion unit, converts the organic sulfur in the stream I into hydrogen sulfide to form the stream II, and the conversion unit contains a sodium-modified alumina catalyst; the stream II enters the cooling Unit to form stream III; stream III enters the adsorption unit composed of at least two adsorption towers connected in parallel to remove hydrogen sulfide from blast furnace gas to form clean gas stream IV. The total sulfur content of stream IV is 15mg / Nm3, and the adsorption tower contains copper modified Molecular sieve adsorption material; at least two adsorption towers in the adsorption unit are used in parallel, and the towers are switched automatically to ensure that at least one tower absorbs sulfide, and the other adsorption tower with saturated adsorption is decomposed and regenerated under the action of high-temperature clean gas, high-temperature clean gas The sulfur-...

Embodiment 3

[0052] The total sulfur concentration in blast furnace gas I is 150mg / m 3 In between, it enters the conversion unit to convert the organic sulfur in stream I into hydrogen sulfide to form stream II, which contains a calcium-modified alumina catalyst; stream II enters the cooling unit to 60°C to form stream III; stream III Enter the adsorption unit composed of at least two adsorption towers connected in parallel to remove hydrogen sulfide in the blast furnace gas to form a clean gas stream IV. The total sulfur content of the stream IV is 20.5mg / Nm3. The adsorption tower contains cobalt modified molecular sieve adsorption materials; the adsorption unit At least two adsorption towers are used in parallel, and the towers are switched automatically to ensure that at least one tower absorbs sulfide, and the other adsorption tower with saturated adsorption is analyzed and regenerated under the action of high-temperature clean gas, and the high-temperature clean gas forms sulfur-rich c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com