Application of tungsten-based catalyst in lignin catalytic hydrogenation for producing aromatic compound

A technology for catalytic hydrogenation of aromatic compounds, applied in the preparation of organic compounds, catalyst carriers, physical/chemical process catalysts, etc., can solve problems such as insufficient yield, difficult catalytic cracking, complex lignin, etc., and achieve low cost, Avoid environmental pollution problems, the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

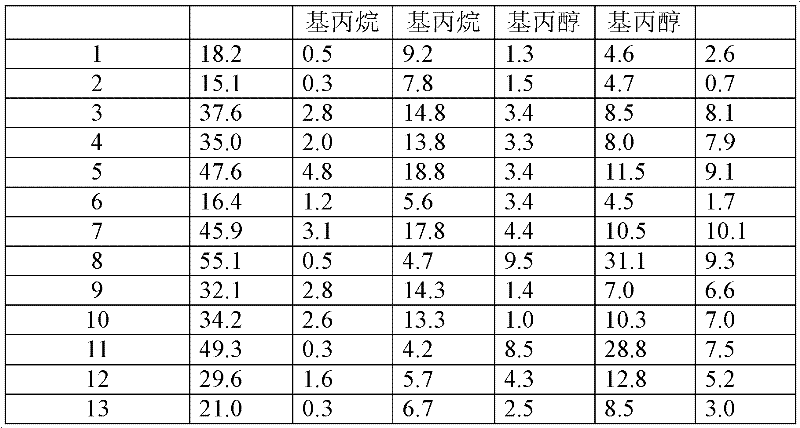

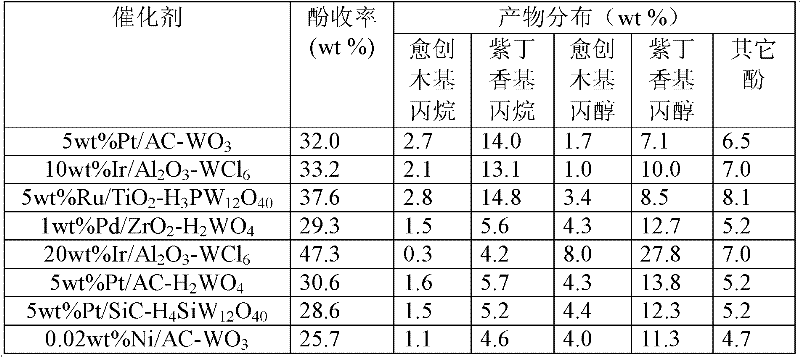

Examples

Embodiment 1

[0025] Activated carbon-supported nickel-tungsten carbide catalyst (Ni-W 2 C / AC) preparation: Ammonium metatungstate and nickel nitrate were prepared into a mixed solution according to the ratio of tungsten / nickel weight ratio of 15:1, wherein the mass concentration of ammonium metatungstate was 0.4g / ml. Then, the mixed solution was impregnated with activated carbon support (AC) by equal volume impregnation method. After being dried in an oven at 120°C for 12 hours, the catalyst precursor was placed in an H2 atmosphere for a temperature-programmed carbothermal reaction. The specific reaction process was: 1.0 g of the precursor was heated from room temperature to 400°C in a quartz reaction tube for 1 hour, and then heated at 1°C. / min to raise the temperature to 700°C and keep it for 1h for carbonization, and the hydrogen flow rate is 60ml / min. Obtained Ni-W with tungsten loading of 30wt% and nickel loading of 2wt% 2 C / AC catalyst, expressed as Ni-W 2 C / AC (2wt%Ni-30wt%W 2 ...

Embodiment 2

[0028] Preparation of Ni-WxC / AC catalyst: The preparation process is similar to Example 1, except that the carbonization temperature is 850°C, and a Ni-WxC / AC catalyst with a tungsten loading of 30wt% and a nickel loading of 2wt% is obtained , where WxC is W 2 Mixed crystal phase of C and WC, 1<x<2. Expressed as Ni-WxC / AC (2wt%Ni-30wt%WxC).

Embodiment 3

[0030] Preparation of WxC / AC catalyst: The preparation process is similar to Example 1, the difference is that only ammonium metatungstate is used in the precursor without adding nickel nitrate, and the carbonization temperature is 800 ° C, thus obtaining W 2 C / AC catalyst; or carbonization at 850°C to obtain WxC / AC catalyst, which is W 2 Mixed crystal phase of C and WC, 1<x<2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com