Method for preparing titanium-based catalyst and synthesizing epoxypropane and dicumyl peroxide

A technology of dicumyl peroxide and cumene hydroperoxide, which is applied in chemical instruments and methods, molecular sieve catalysts, and preparation of peroxygen compounds, and can solve the problems of environmental pollution caused by many by-products and inorganic salt wastewater. , achieve the effects of high atomic economy, overcoming equipment corrosion, and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

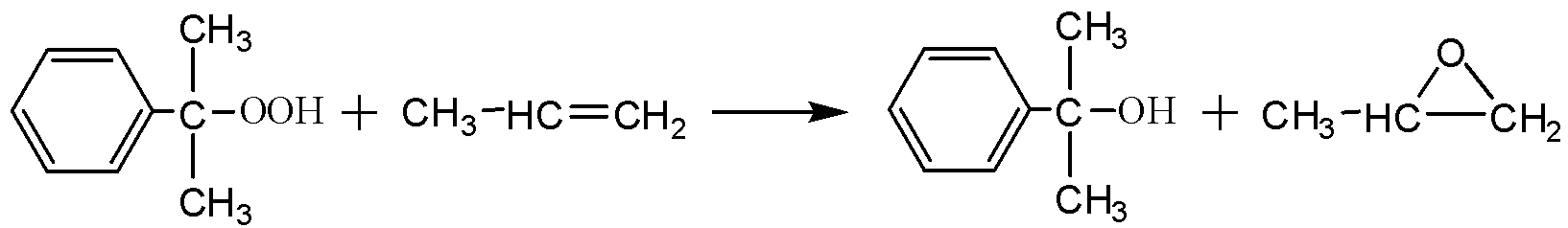

Image

Examples

Embodiment 1

[0030] Propylene epoxidation reaction: Weigh 1.0 g of 20-40 mesh catalyst, and fill it in a stainless steel fixed-bed tubular reactor with an inner diameter of 6 mm. After the reaction temperature stabilizes at 90 ℃, the feeding reaction starts. The system pressure is 4 MPa, the propylene is fed in the liquid phase, the feed rate is 6 ml / h, the CHP (mass fraction is about 30%, the other components are cumene, 3% n-butylamine), the feed rate is 10 L / h, propylene The molar ratio to cumene hydrogen peroxide is about 5, and the total mass space velocity (WHSV) is 12.4 h -1 . The reaction product was collected in a cold trap, and samples were taken every 1 hour to analyze the product composition. After 10 hours of reaction, calculate the average value, the conversion rate of cumene hydroperoxide X CHP 62.3%, the utilization rate of cumene hydrogen peroxide U CHP 63.5%, selectivity S for propylene oxide PO PO It was 94.3%.

[0031] After the reaction in the previous step is over, tak...

Embodiment 2

[0034] Propylene epoxidation reaction: reaction temperature is 100 ℃, other conditions are the same as in Example 1, react for 10 hours, calculate the average value, conversion rate of cumene hydroperoxide X CHP Is 77.9%, the utilization rate of cumene hydrogen peroxide U CHP 60.4%, selectivity S of propylene oxide PO PO It was 92.6%.

[0035] After the reaction in the previous step is over, take 150 ml of the product and distill out the propylene oxide, 1,2-propylene glycol, n-butylamine and other low-boiling substances in the product. The product contains about 8.7 g of cumene hydroperoxide CHP. Containing about 18.5 g of α,α-dimethylbenzyl alcohol, add 7.3 g of 70% CHP to a three-necked flask to make the molar ratio of α,α-dimethylbenzyl alcohol to cumene hydrogen peroxide approximately 1.5. The remaining steps are the same as in Example 1, and then the synthesis of dicumyl peroxide DCP is carried out, and 19.3 g of DCP product can be obtained, and the yield is about 78.9%.

Embodiment 3

[0037] Propylene epoxidation reaction: the reaction temperature is 100°C, the amount of catalyst is 2.0 g, other conditions are the same as in Example 1, and the reaction is 10 hours, and the average value is calculated. The conversion rate of cumene hydroperoxide is X CHP Is 84.9%, the utilization rate of cumene hydrogen peroxide U CHP 61.6%, selectivity S of propylene oxide PO PO It was 93.1%.

[0038] After the reaction in the previous step is over, take 150 ml of the product and distill out the propylene oxide, 1,2-propylene glycol, n-butylamine and other low-boiling substances in the product. The product contains about 5.9 g of cumene hydroperoxide CHP. Containing about 20.6 g of α,α-dimethylbenzyl alcohol DMPC, add 13.4 g of 70% CHP to a three-necked flask to make the molar ratio of α,α-dimethylbenzyl alcohol to cumene hydrogen peroxide approximately The other steps are the same as in Example 1, and then the synthesis of dicumyl peroxide DCP is carried out, and 21.7 g of DC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com