Method for recycling lithium, iron and current collector-aluminum foil in positive electrode material of waste lithium iron phosphate battery

A lithium iron phosphate battery and positive electrode material technology, which is applied in battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of iron phosphate price increase, lithium salt price increase, resource waste, etc., and achieve low processing cost, The effect of high recovery rate and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

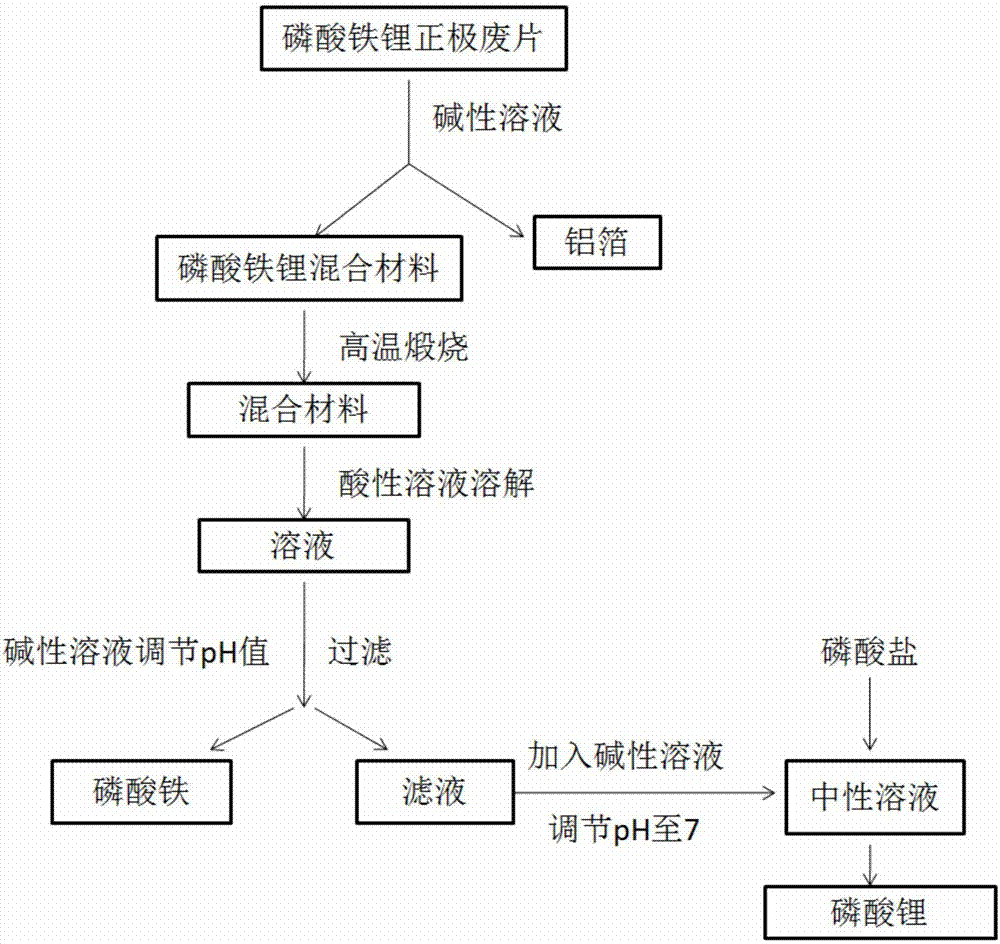

Method used

Image

Examples

Embodiment 1

[0040] (1) Place the positive electrode sheet of the waste lithium iron phosphate battery to be recovered in a 0.1mol / L sodium hydroxide solution for stirring, ultrasonic treatment, and after the active material lithium iron phosphate mixed material is completely detached from the aluminum foil, remove the aluminum foil from the aluminum foil It can be directly recovered after being separated from the lye.

[0041] (2) After filtering and separating the lithium iron phosphate mixed material in the lye in step (1), put it in an oven at 80° C. for 10 hours to dry.

[0042] (3) Place the dried lithium iron phosphate mixed material in step (2) in a kiln at 500° C. for calcination for 5 hours. The calcined mixed material is subjected to ball milling, and the powder after ball milling is sieved by vibration. The sieve The net is 500 mesh.

[0043] (4) Put the mixed material calcined in step (3) into 4 mol / L sulfuric acid solution and stir for 6 hours to completely dissolve it.

[...

Embodiment 2

[0051] (1) Place the positive electrode sheet of the waste lithium iron phosphate battery to be recovered in 0.2mol / L potassium hydroxide solution for stirring, ultrasonic treatment, after the active material lithium iron phosphate mixed material is completely detached from the aluminum foil, remove the aluminum foil from the aluminum foil It can be directly recovered after being separated from the lye.

[0052] (2) After filtering and separating the lithium iron phosphate mixed material in the lye in step (1), put it into an oven at 80° C. to dry for 8 hours.

[0053] (3) Place the dried lithium iron phosphate mixed material in step (2) in a kiln at 400° C. for calcination for 6 hours. The calcined mixed material is ball milled, and the powder after ball milling is sieved by vibration. The sieve The net is 600 mesh.

[0054] (4) Put the mixed material calcined in step (3) into 6 mol / L hydrochloric acid solution and stir for 4 hours to completely dissolve it.

[0055] (5) Sl...

Embodiment 3

[0062] (1) Place the recovered positive electrode waste material of lithium iron phosphate battery in 0.5mol / L lithium hydroxide solution for stirring, ultrasonic treatment, after the active material lithium iron phosphate mixed material is completely detached from the aluminum foil, remove the aluminum foil from the alkali It can be recovered directly after being separated from the liquid.

[0063] (2) After filtering and separating the lithium iron phosphate mixed material in the lye in step (1), put it into an oven at 80° C. to dry for 8 hours.

[0064] (3) Place the dried lithium iron phosphate mixed material in step (2) in a kiln at 600° C. for calcination for 3 hours. The calcined mixed material is subjected to ball milling, and the powder after ball milling is sieved by vibration. The sieve The net is 300 mesh.

[0065] (4) Put the mixed material calcined in step (3) into 2 mol / L nitric acid solution and stir for 6 hours to dissolve it completely.

[0066] (5) Slowly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com