Methyl propionate preparation method

A technology of methyl propionate and methanol, which is applied in the field of preparation of methyl propionate, can solve the problems of tedious preparation of ionic liquid catalyst, high price, high energy consumption of homogeneous palladium catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

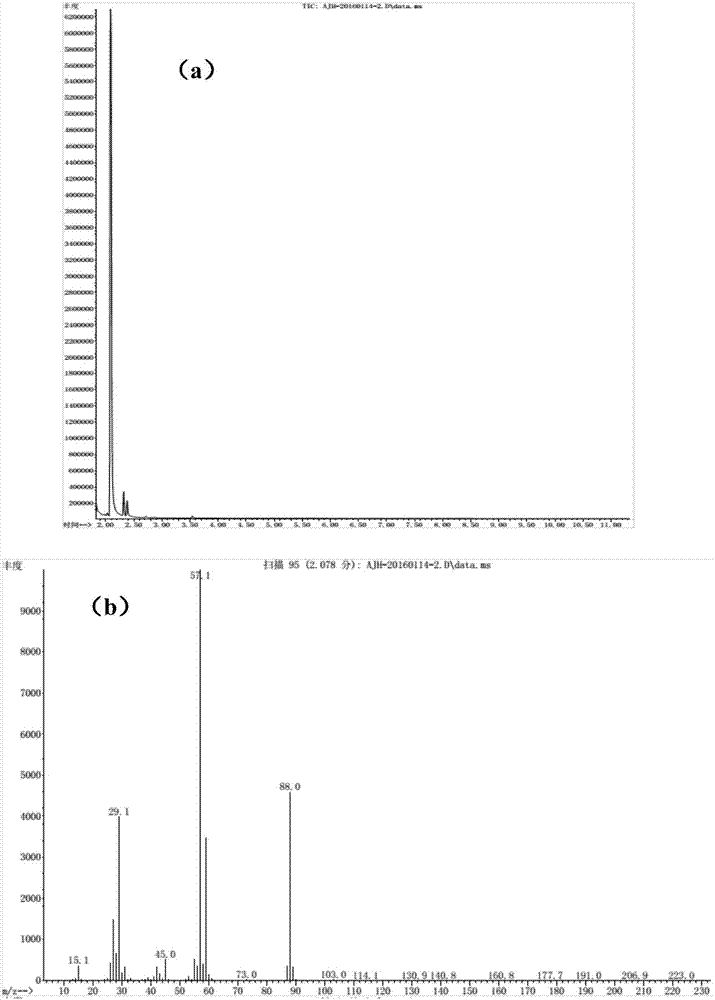

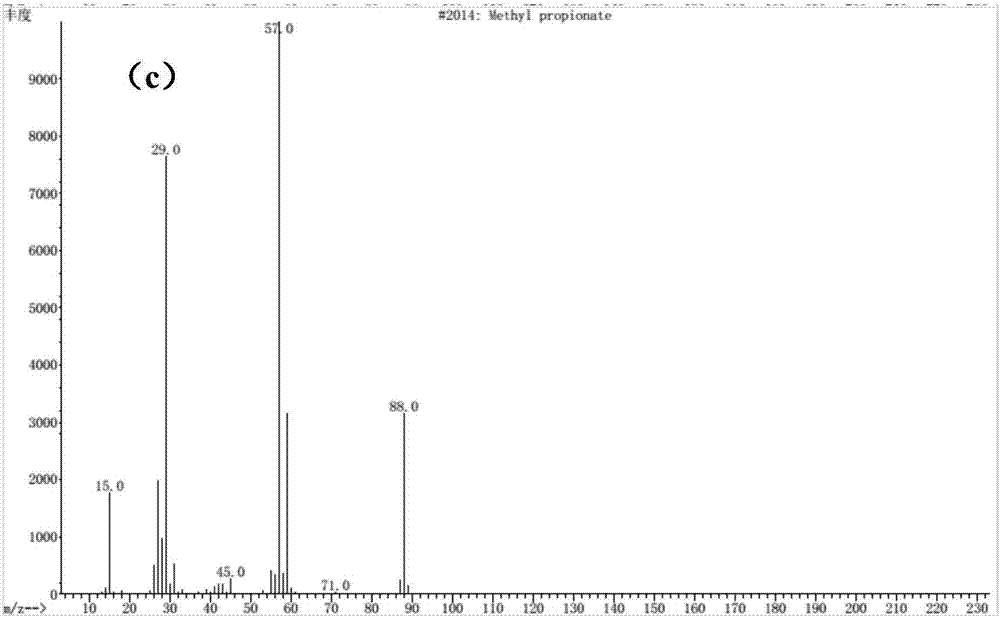

Image

Examples

Embodiment 1

[0028] Weigh 2g 2wt%Ru / CeO 2 Catalyst, 14-25 mesh catalyst is sieved after forming and filled into the reaction tube, the bed height is 9mm, the reaction pressure is 2.0MPa, the reaction temperature is 200°C, and the ethylene volume space velocity is 450h -1 , CO volume space velocity 2000h -1 , methanol volumetric space velocity 5h -1 , every 3h sampling chromatographic analysis, the yield of methyl propionate was 70%.

Embodiment 2

[0030] Weigh 3.3g 2wt%Ru / TiO 2 , forming a 14-25 mesh catalyst and filling it into a reaction tube, filling a 15mm bed, and reacting at 200°C under a pressure of 2.0MPa, and the ethylene volume space velocity is 100h -1 , CO volume space velocity 2000h -1 , methanol volume space velocity 10h -1 , every 3h sampling chromatographic analysis, the yield of methyl propionate was 30%.

Embodiment 3

[0032] Weigh 3.3g 2wt%Ru / CeO 2 , take 14-25 mesh catalyst and fill it into the reaction tube, fill it with 15mm bed, and react at 200℃ under the pressure of 2.0MPa, and the volume space velocity of ethylene is 450h -1 , CO volume space velocity 2000h -1 , methanol volume space velocity 20h -1 , every 3h sampling chromatographic analysis, the yield of methyl propionate was 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com