Regeneration method and equipment of selective catalytic reduction (SCR) denitration catalyst

A technology for denitrification catalysts and regeneration equipment, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as complex operation, low activity, and impracticality, and achieve improved efficiency and extended use Effect of life and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

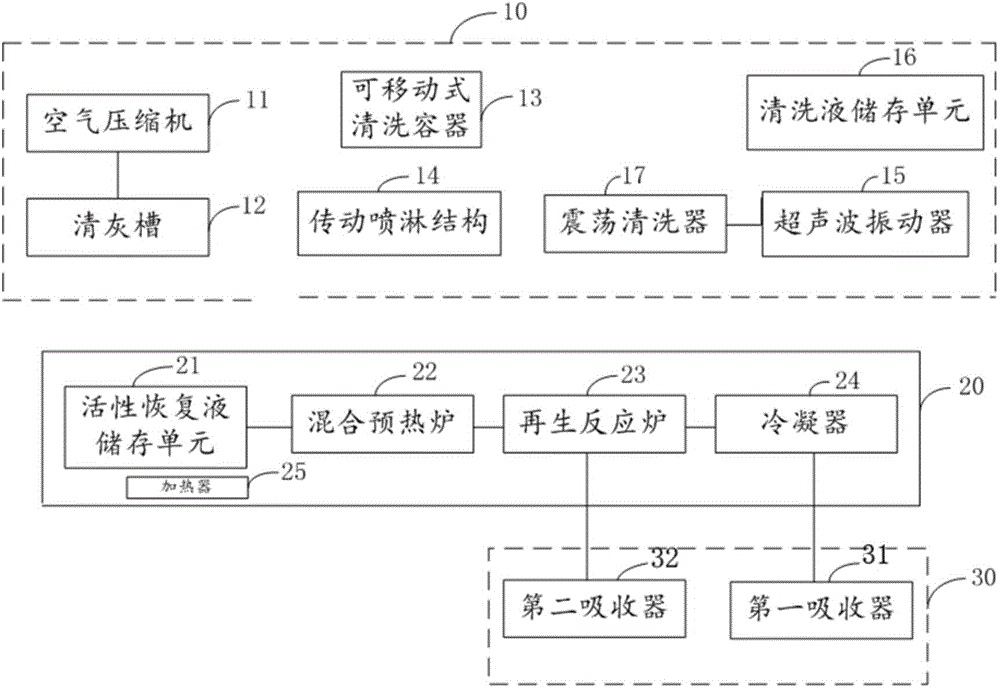

[0019] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

[0020] figure 1 It is a schematic flow chart of the SCR denitration catalyst regeneration method of the present invention, combined with figure 1 Shown, the present invention provides a kind of regeneration method of SCR denitration catalyst, comprises the following steps,

[0021] A1: The pre-stage cleaning process removes dust and impurity particles on the catalyst. In this embodiment, the front-stage cleaning process includes: a soot cleaning process and a cleaning process. Further, the cleaning process can be performed first and then the cleaning process, or the cleaning process can be performed first and then the cleaning process can be performed.

[0022] In the cleaning process, the SCR denitration catalyst is blown through the high-pressure nozzle of the air compressor to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com