Electric plating cyanide-containing waste water treatment method

A treatment method, cyanide wastewater technology, applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems affecting the factory environment, affecting water quality, water pollution, etc., to reduce pollution and improve chemical reaction efficiency , to ensure the effect of the living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

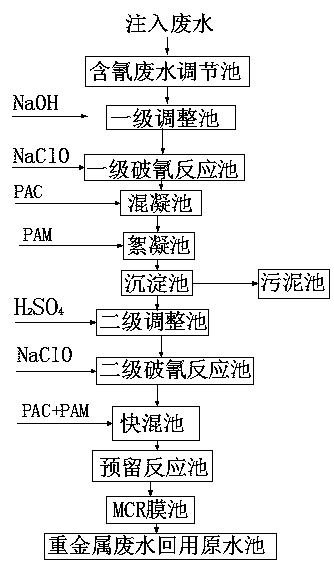

[0025] Such as figure 1 Shown, a kind of electroplating cyanide wastewater treatment method comprises the following steps:

[0026] S1. Adjustment of cyanide-containing wastewater: the wastewater collected by the pipe network is discharged into the cyanide-containing wastewater adjustment tank, and then the wastewater is tempered for 1 hour, and after the wastewater is uniformly tempered, enter the next step;

[0027] S2, first-level adjustment: extract the uniform wastewater in S1 into the first-level adjustment tank, then add liquid NaOH to the first-level adjustment tank, and after uniform mixing, the pH value of the solution in the first-level adjustment tank is 10;

[0028] S3, primary cyanide breaking reaction: transport the wastewater in the adjustment tank to the primary cyanide breaking reaction tank through a water pump, then add NaClO into the primary cyanide breaking reaction tank, and stir evenly for 20 minutes with a mixer, wherein the ORP of the waste liquid is ...

Embodiment 2

[0042] Such as figure 1 Shown, a kind of electroplating cyanide wastewater treatment method comprises the following steps:

[0043] S1. Adjustment of cyanide-containing wastewater: the wastewater collected by the pipe network is discharged into the cyanide-containing wastewater adjustment tank, and then the wastewater is tempered for 1.5 hours, and after the wastewater is uniformly tempered, enter the next step;

[0044] S2, first-level adjustment: extract the uniform wastewater in S1 into the first-level adjustment tank, then add liquid NaOH to the first-level adjustment tank, and after uniform mixing, the pH value of the solution in the first-level adjustment tank is 10.5;

[0045] S3, primary cyanide breaking reaction: transport the wastewater in the adjustment tank to the primary cyanide breaking reaction tank through a water pump, then add NaClO into the primary cyanide breaking reaction tank, and stir evenly for 25 minutes with a mixer, wherein the ORP of the waste liqui...

Embodiment 3

[0059] Such as figure 1 Shown, a kind of electroplating cyanide wastewater treatment method comprises the following steps:

[0060] S1. Adjustment of cyanide-containing wastewater: the wastewater collected by the pipe network is discharged into the cyanide-containing wastewater adjustment tank, and then the wastewater is tempered for 2 hours, and after the wastewater is evenly tempered, enter the next step;

[0061] S2, first-level adjustment: extract the uniform wastewater in S1 into the first-level adjustment tank, then add liquid NaOH to the first-level adjustment tank, and after uniform mixing, the pH value of the solution in the first-level adjustment tank is 11;

[0062] S3, primary cyanide breaking reaction: transport the wastewater in the adjustment tank to the primary cyanide breaking reaction tank through the water pump, then add NaClO into the primary cyanide breaking reaction tank, and stir evenly for 30 minutes through the mixer, wherein the ORP of the waste liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com