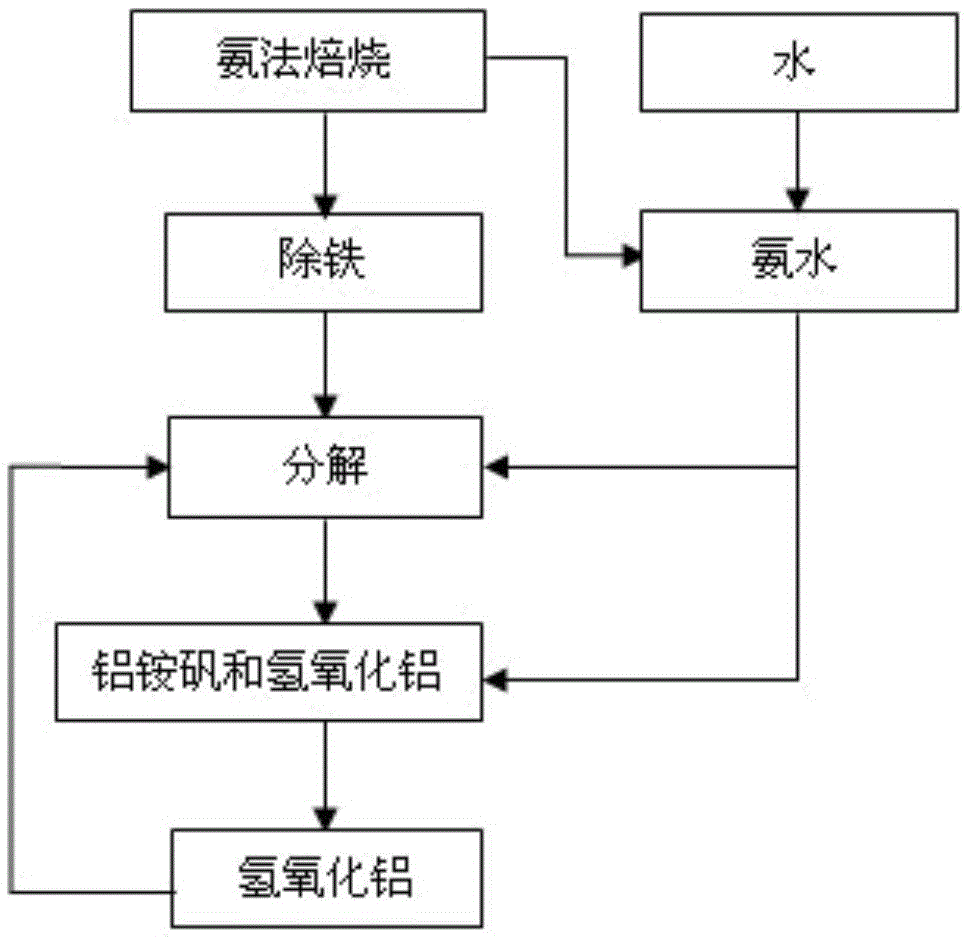

A method for preparing aluminum hydroxide by using ammonia water to decompose fly ash dissolution liquid

A technology of aluminum hydroxide and fly ash, which is applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve problems such as pollution, high cost, and large investment in fly ash equipment, and achieve simple processes and facilitate industrialization , the effect of easy solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Fly ash ammonia roasting and dissolution is to mix fly ash and ammonium sulfate at a weight ratio of 1:4, then roast at a temperature of 350°C for 5 hours, and absorb the ammonia gas generated by roasting with water to obtain ammonia water with a concentration of 20wt%. Dissolution was carried out at 60°C according to the weight ratio of water and sintered product at 3:1 to obtain an aluminum sulfate solution containing a small amount of iron sulfate, and the iron ions in the solution were removed by a cation exchange resin method to obtain an aluminum sulfate solution with a concentration of 190g / L , the pH value of the aluminum sulfate solution is 1.3, measure 800ml of iron removal solution, adjust the pH value of the solution at 70°C in the early stage, adjust the pH value of the solution to 2.1 with ammonia water for 45 minutes, and stir at a stirring rate of 300r / min, Add 160g of aluminum hydroxide seed crystals to make the solid content of the solution reach 180g / L...

Embodiment 2

[0035] Fly ash ammonia roasting and dissolution is to mix fly ash and ammonium sulfate at a weight ratio of 1:5, roast at a temperature of 400°C for 4 hours, and absorb the ammonia gas generated by roasting with water to obtain ammonia water with a concentration of 25wt%. Dissolution is carried out at 95°C according to the weight ratio of water and sintered product at 2.5:1 to obtain an aluminum sulfate solution containing a small amount of iron sulfate, and the iron ion in the solution is removed by a cation exchange resin method to obtain an aluminum sulfate solution with a concentration of 200g / L , the pH value of the aluminum sulfate solution is 1.6, measure 1000ml of iron removal solution, adjust the pH value of the previous solution at 95°C, adjust the pH value of the solution to 2.8 with ammonia water for 60 minutes, and stir at a stirring rate of 400r / min , Add 210g of aluminum hydroxide seed crystals to make the solid content of the solution reach 200g / L.

[0036] Pas...

Embodiment 3

[0040] Fly ash ammonia roasting and dissolution is to mix fly ash and ammonium sulfate at a weight ratio of 1:5.5, then roast at a temperature of 570°C for 3.5 hours, and absorb the ammonia gas generated by roasting with water to obtain ammonia water with a concentration of 22wt%. Dissolution was carried out at 60°C according to the weight ratio of water and sintered product at 2:1 to obtain an aluminum sulfate solution containing a small amount of iron sulfate, and the iron ions in the solution were removed by a cation exchange resin method to obtain an aluminum sulfate solution with a concentration of 210g / L , the pH value of the aluminum sulfate solution is 1.3, measure 700ml of iron removal solution, adjust the pH value of the solution at 70°C in the early stage, adjust the pH value of the solution to 2.5 with ammonia water for 45 minutes, and stir at a stirring rate of 300r / min, Add 160g of aluminum hydroxide seed crystals to make the solid content of the solution reach 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com