Process and device for continuous acidification of acidification section in production of sebacic acid

A sebacic acid and process technology, applied in the field of continuous acidification process and its process equipment, can solve problems such as restricting the development of enterprises and industries, waste of water resources, energy, and inability to achieve continuous production, and achieve quality assurance, stable operation, and overcoming problems. The effect of corrosion and acidification crystallizing tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

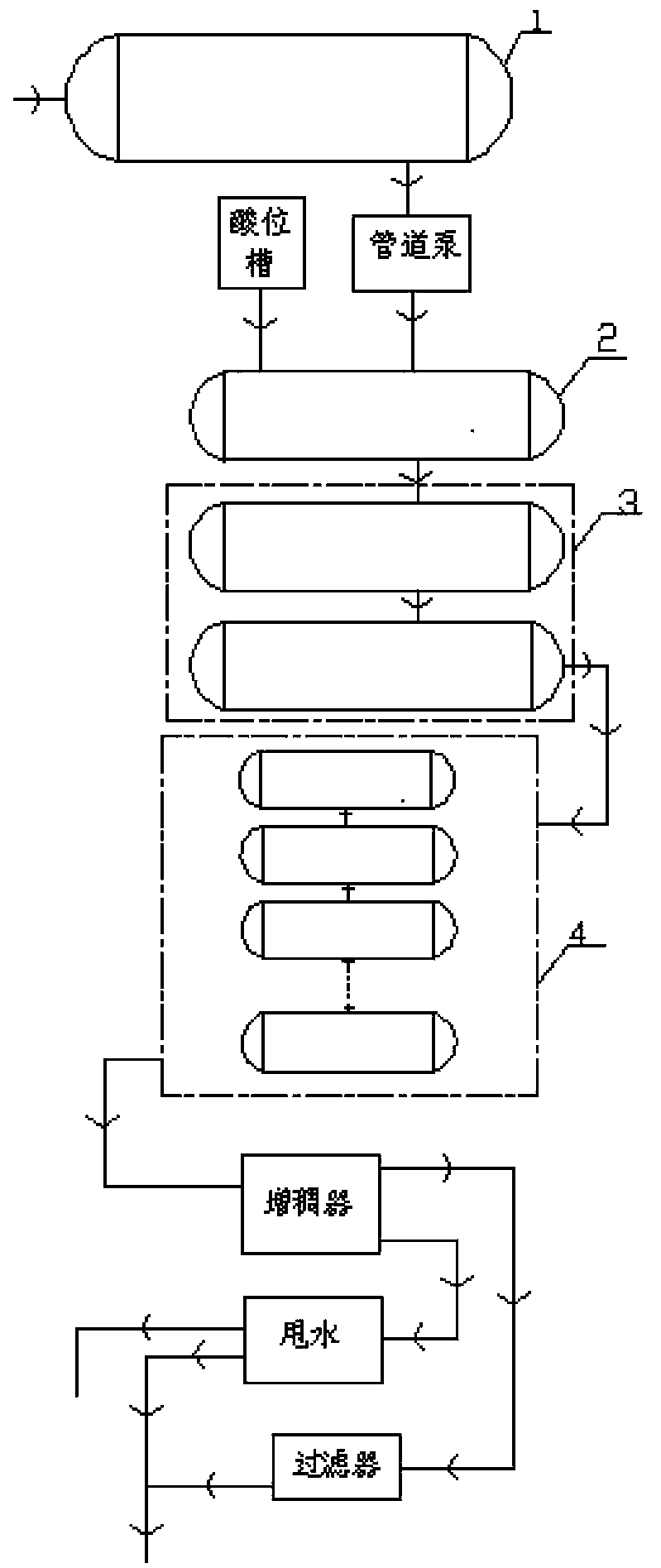

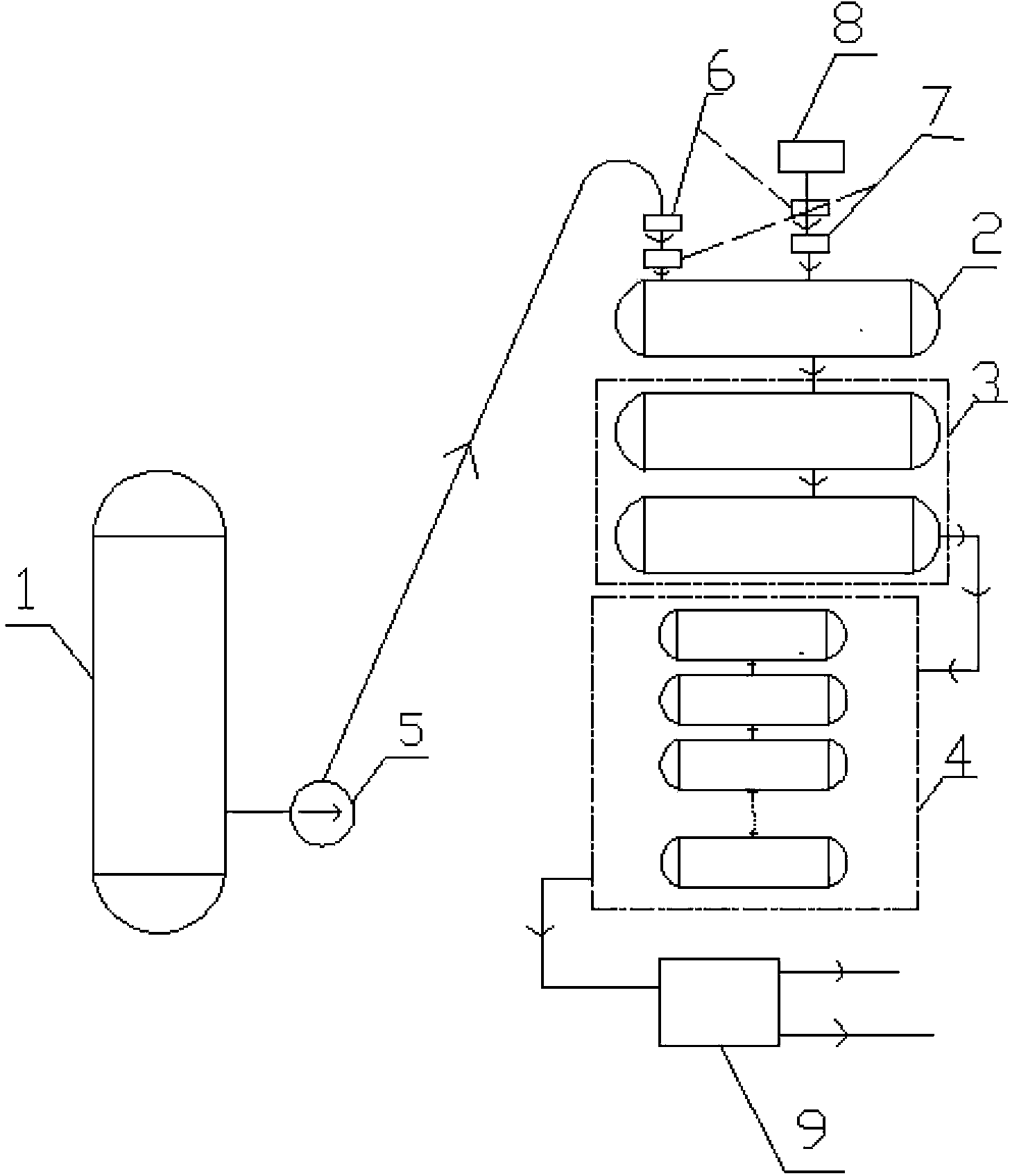

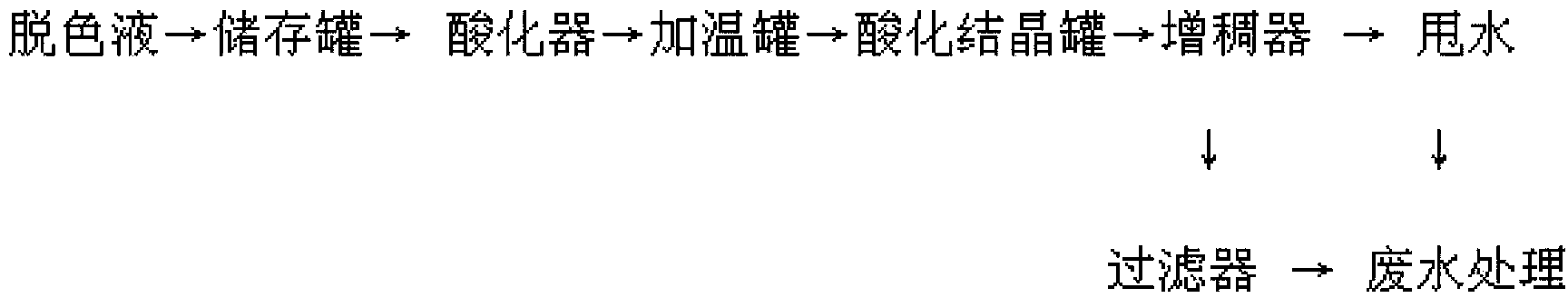

[0027] According to the sebacic acid production continuous acidification process of the present invention, comprises the following steps:

[0028]The decolorizing liquid is heated to 92°C with steam in the storage tank, pumped into the acidifier through a rotameter with a pipeline pump, and at the same time, sulfuric acid is added to the acidifier at a ratio of 15% to control the pH value of the feed liquid at 2. The liquid flows from the acidifier to the first heating tank by virtue of the high level difference, and the heater is used in the first heating tank to heat the feed liquid to above 100°C, so that the feed liquid is mixed and boiled, and the feed liquid flows to the second heating tank by itself. Continue heating to further make the feed liquid fully boil. The feed liquid flows from the second heating tank to the acidification crystallization tank. 27 revolutions per minute, after the feed liquid passes through the fourth to seventh stage acidification crystallizati...

Embodiment 2

[0030] According to the sebacic acid production continuous acidification process of the present invention, comprises the following steps:

[0031] The decolorizing liquid is heated to 96°C with steam in the storage tank, pumped into the acidifier through a rotameter with a pipeline pump, and at the same time, sulfuric acid is added to the acidifier at a ratio of 18%, and the pH value of the feed liquid is controlled at 1.5. The liquid flows from the acidifier to the first heating tank by virtue of the high level difference, and the heater is used in the first heating tank to heat the feed liquid to above 100°C, so that the feed liquid is mixed and boiled, and the feed liquid flows to the second heating tank by itself. Continue heating to further make the feed liquid fully boil. The feed liquid flows from the second heating tank to the acidification crystallization tank. 30 revolutions per minute, after the feed liquid passes through the fourth to seventh stage acidification cr...

Embodiment 3

[0033] According to the sebacic acid production continuous acidification process of the present invention, comprises the following steps:

[0034] The decolorization liquid is heated to 97°C with steam in the storage tank, and then pumped into the acidifier through a rotameter with a pipeline pump. At the same time, 20% sulfuric acid is added to the acidifier to control the pH value of the feed liquid at 1.5. The liquid flows from the acidifier to the first heating tank by virtue of the high level difference, and the heater is used in the first heating tank to heat the feed liquid to above 100°C, so that the feed liquid is mixed and boiled, and the feed liquid flows to the second heating tank by itself. Continue heating to further make the feed liquid fully boil. The feed liquid flows from the second heating tank to the acidification crystallization tank. 25 revolutions per minute, after the feed liquid passes through the acidification crystallization tank from the fourth to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com