Graphene catalytic plate capable of efficiently purifying automobile exhaust and preparation method

A technology of automobile exhaust and ene catalytic plate, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve the problems of short circulation time of engine exhaust gas, insufficient purification of poisonous gases, and insufficient purification. , to achieve the effect of increasing the surface area, easy process control, and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

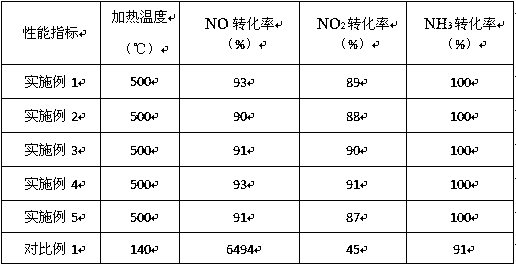

Examples

Embodiment 1

[0033] A preparation method of a graphene catalytic plate for efficiently purifying automobile exhaust gas, comprising the following steps:

[0034] Step 1: Stir and mix graphene and water according to a volume ratio of 1:3, heat at 100°C, and mechanically stir at a constant speed for 30 minutes to obtain a dispersion;

[0035] Step 2: Add a polyvinyl alcohol aqueous solution with a concentration of 30% to the dispersion in step 1. The volume of the polyvinyl alcohol aqueous solution is 1 / 2 of the volume of the dispersion prepared in step 1, and mix and stir evenly;

[0036] Step 3: Add a mixture of micronized metal oxide cerium oxide and aluminum oxide to the liquid obtained in step 2, and stir well to obtain a mixed slurry of metal oxide, graphene and polyvinyl alcohol; graphene and metal oxide The mass ratio is 1:1;

[0037] Step 4: Add titanium hydride to the mixed slurry prepared in step 3, the amount of titanium hydride is 0.01% of the mass of the slurry, and the slurry i...

Embodiment 2

[0041] A preparation method of a graphene catalytic plate for efficiently purifying automobile exhaust gas, comprising the following steps:

[0042] Step 1: Stir and mix graphene and water according to a volume ratio of 1:3, heat at 100°C, and mechanically stir at a constant speed for 30 minutes to obtain a dispersion;

[0043] Step 2: Add a polyvinyl alcohol aqueous solution with a concentration of 30% to the dispersion in step 1. The volume of the polyvinyl alcohol aqueous solution is 2 / 3 of the volume of the dispersion prepared in step 1, and mix and stir evenly;

[0044] Step 3: Add a mixture of micronized metal oxide alumina, lanthanum oxide and vanadium oxide to the liquid obtained in step 2, and stir well to obtain a mixed slurry of metal oxide, graphene and polyvinyl alcohol; graphene and The mass ratio of metal oxides is 1:2;

[0045] Step 4: Add titanium hydride to the mixed slurry prepared in step 3, the amount of titanium hydride is 0.02% of the mass of the slurry...

Embodiment 3

[0049] A preparation method of a graphene catalytic plate for efficiently purifying automobile exhaust gas, comprising the following steps:

[0050] Step 1: Stir and mix graphene and water according to a volume ratio of 1:3, heat at 100°C, and mechanically stir at a constant speed for 30 minutes to obtain a dispersion;

[0051] Step 2: Add a polyvinyl alcohol aqueous solution with a concentration of 30% to the dispersion in step 1. The volume of the polyvinyl alcohol aqueous solution is 1 / 2 of the volume of the dispersion prepared in step 1, and mix and stir evenly;

[0052] Step 3: Add a mixture of micronized metal oxide silicon dioxide and vanadium oxide at a mass ratio of 5:1 to the liquid obtained in step 2, and stir well to obtain a mixed slurry of metal oxide, graphene and polyvinyl alcohol Material; The mass ratio of graphene and metal oxide is 1:5;

[0053] Step 4: Add titanium hydride to the mixed slurry prepared in step 3, the amount of titanium hydride is 0.04% of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com