Chemical mixed reaction vessel for separating turbulent flow

A reaction vessel and chemical technology, applied in the field of chemical mixing reaction vessels, can solve the problems of insufficient mixing degree of reactants, easy clogging of filter components, insufficient reaction, etc., and achieve the effects of improving chemical reaction efficiency, convenient operation and avoiding clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

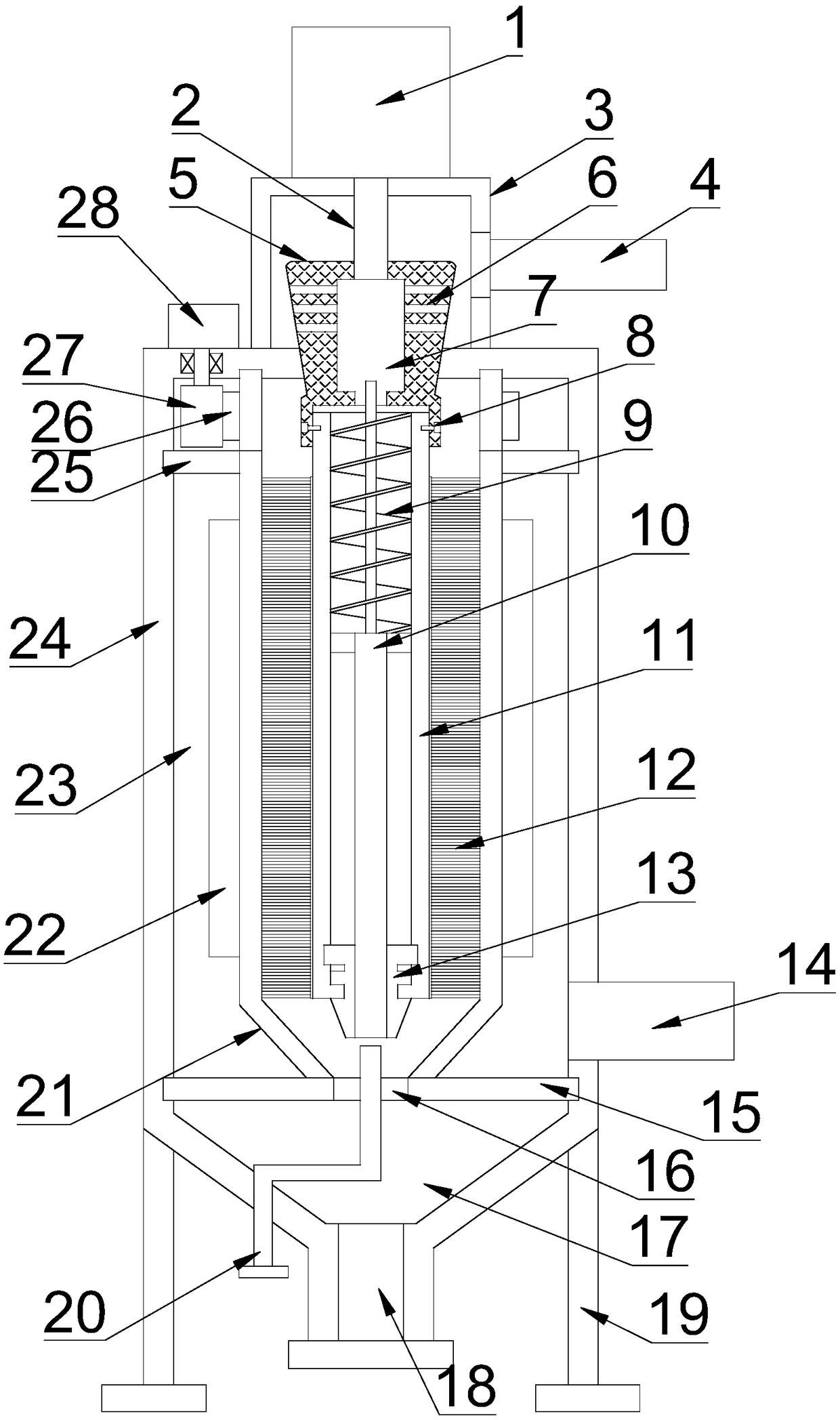

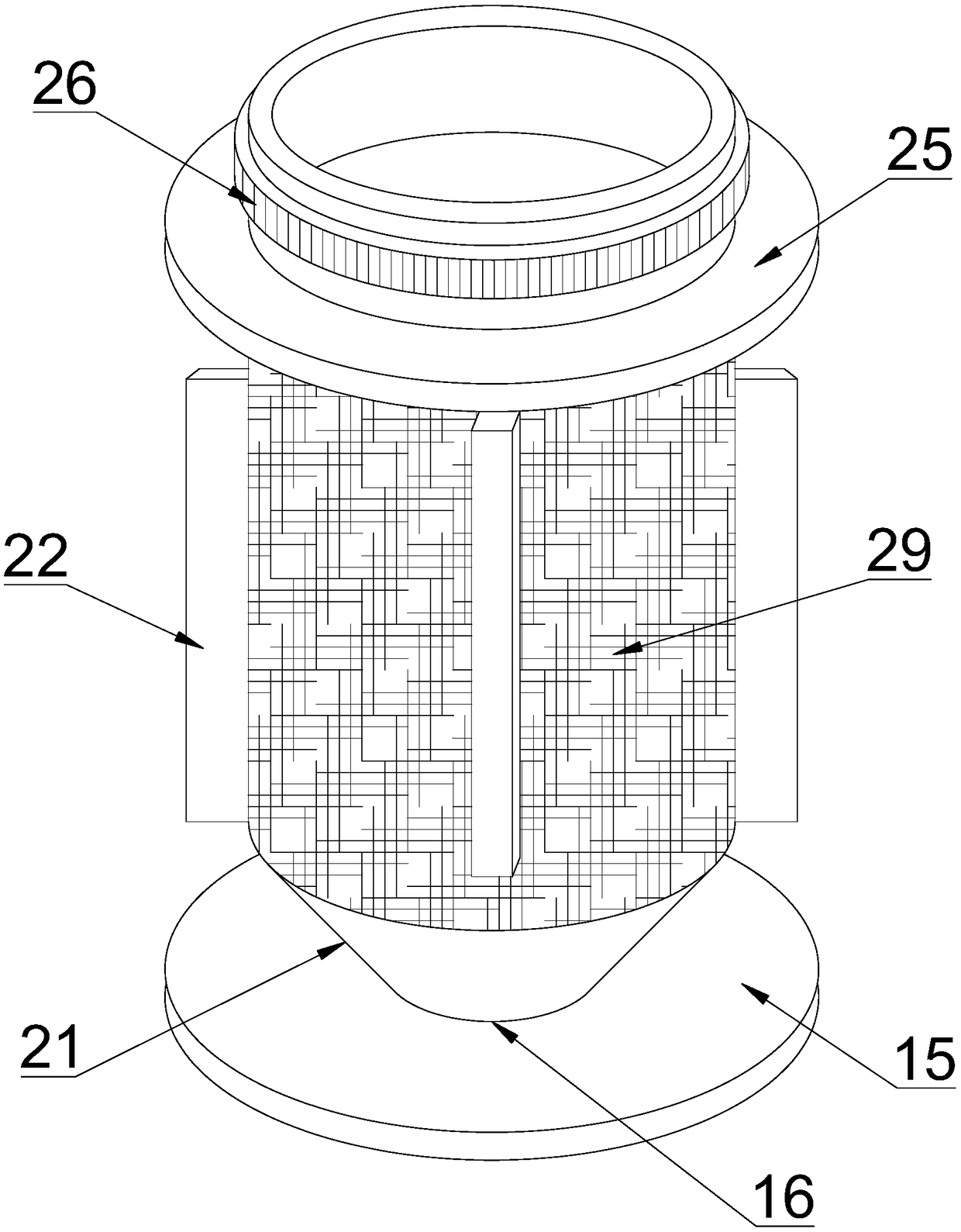

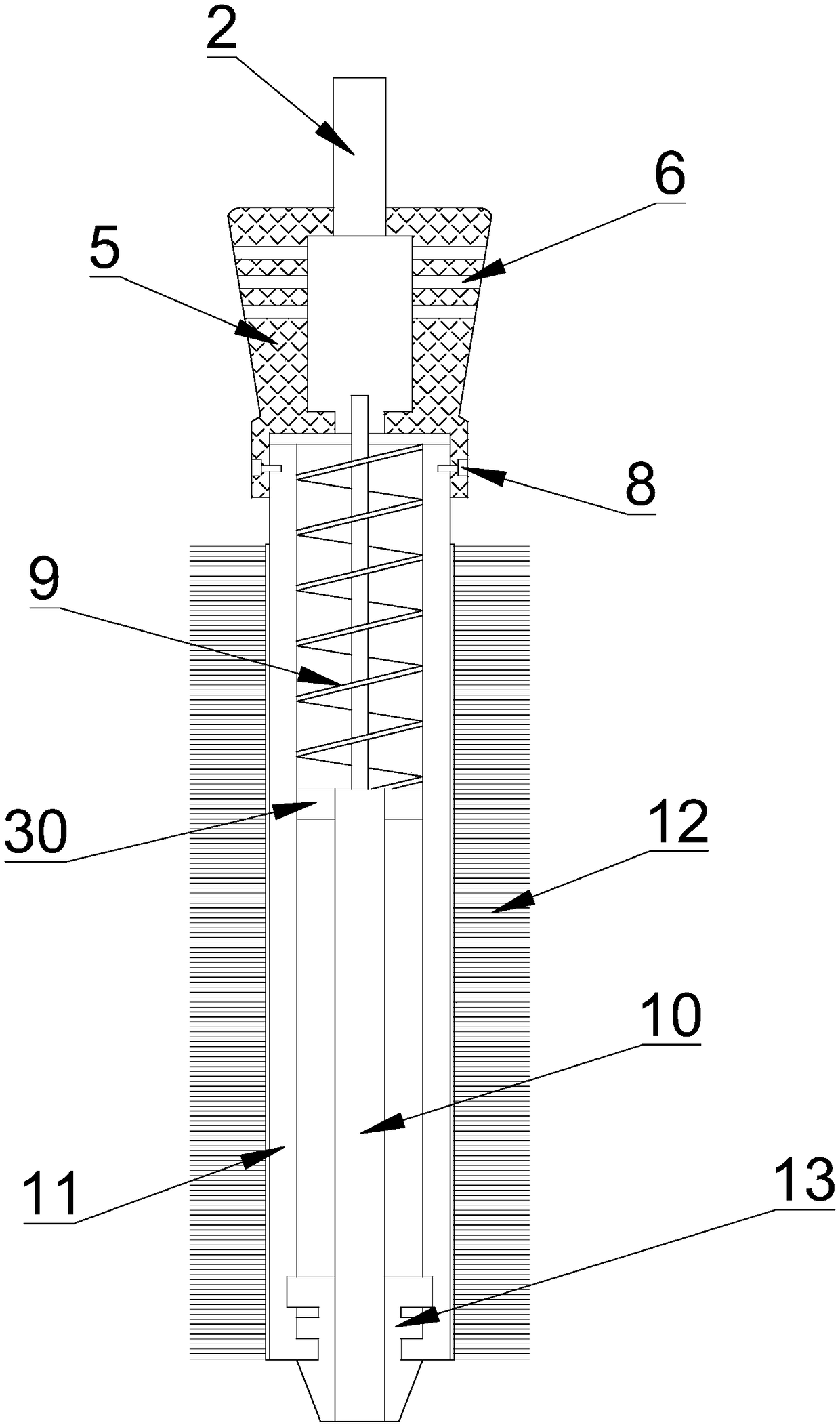

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] see Figure 1-3 , a chemical mixing reaction vessel for separation and turbulence, comprising a guide cylinder 11, a cleaning brush 12, a rotating cylinder 21 and a reaction tank body 24, the reaction tank body 24 is installed on a support 19, and the inside of the reaction tank body 24 is installed with Rotating cylinder 21, the bottom of rotating cylinder 21 is welded with a lower partition 15, the lower partition 15 is embedded in the groove of the inner wall of the reaction tank body 24 and rotated along the groove, and the middle part of the lower partition 15 is provided with a slag discharge port 16. The slag outlet 16 communicates with the upper rotating cylinder 21 and the slag outlet 16 communicates with the lower slag collection chamber 17. The interior of the reaction tank 24 below the lower partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com