Kiln gas semi-dry process defluorination desulphurization dedusting equipment

A technology of desulfurization and dust removal equipment and semi-dry method, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of poor defluorination and desulfurization effects, waste of raw materials, inconvenient dust collection and transportation, etc., and delay the drying time , Improve desulfurization efficiency and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

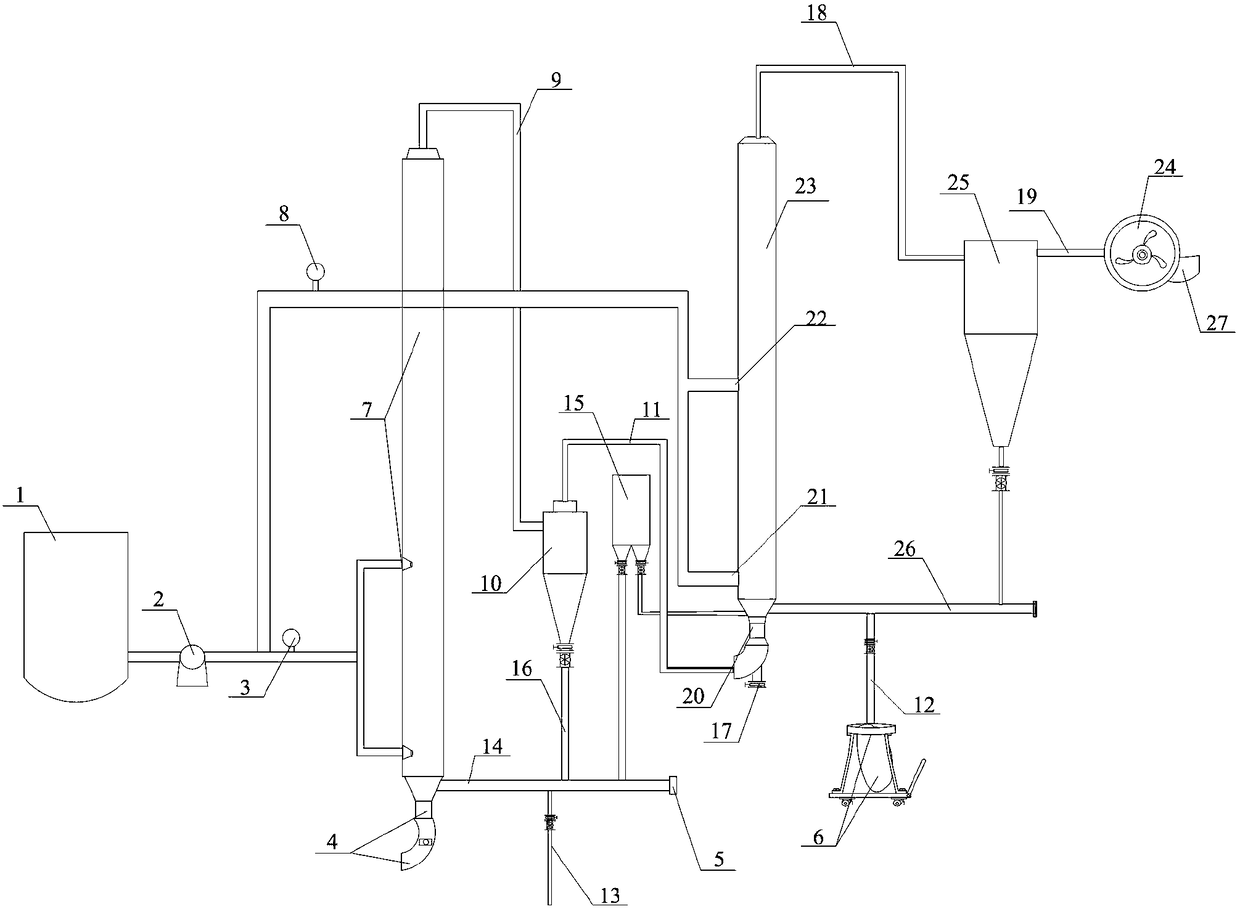

[0039] as attached figure 1 to attach Figure 6 shown

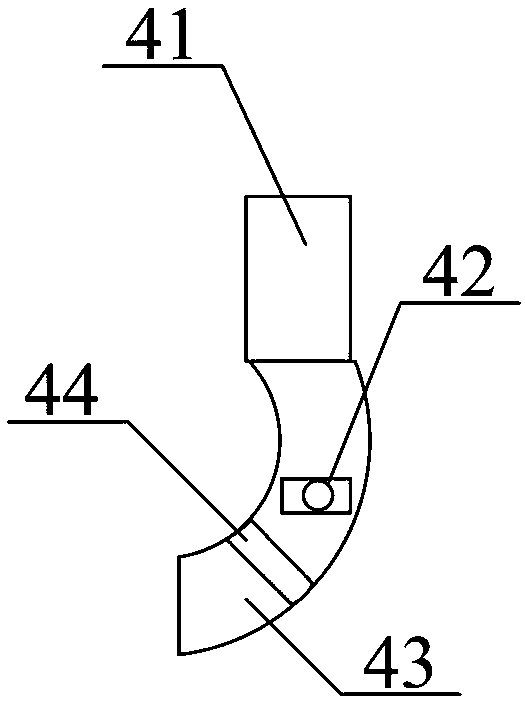

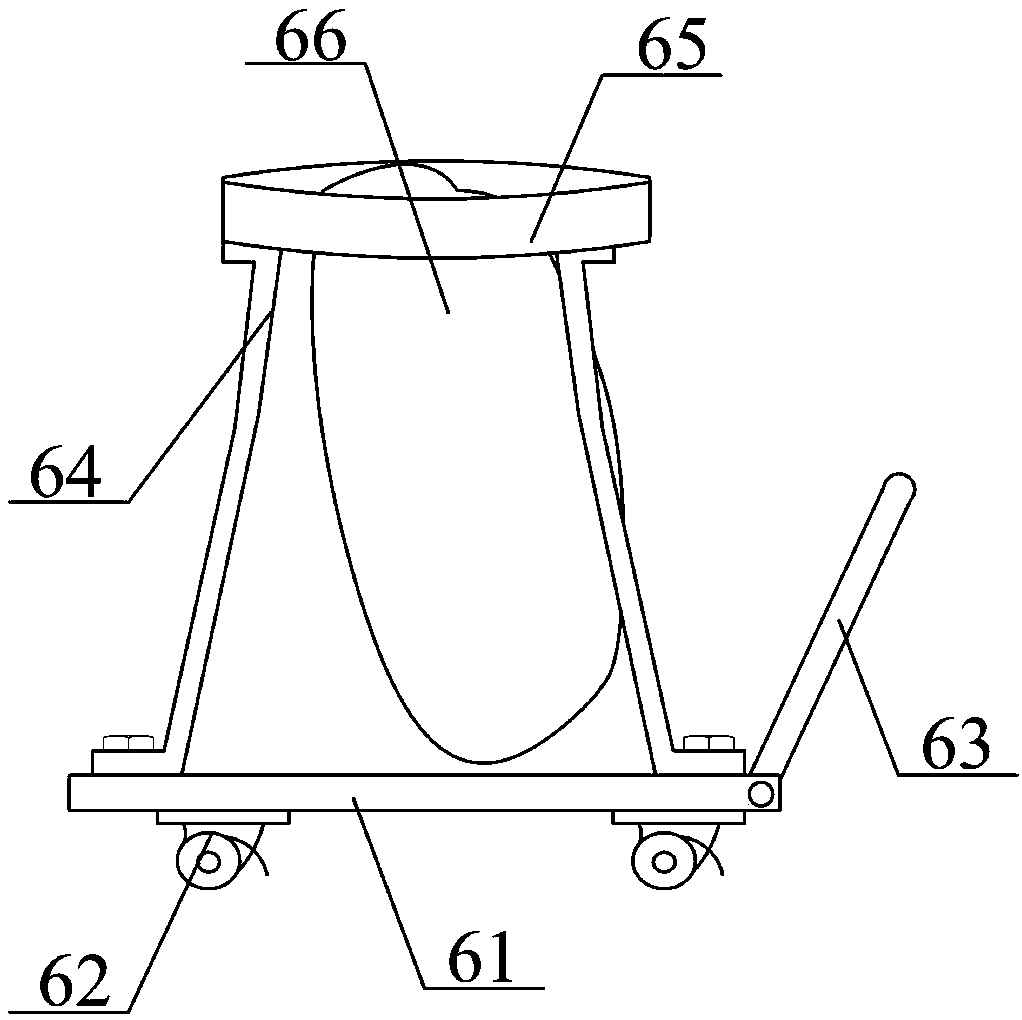

[0040] The present invention provides semi-dry defluorination, desulfurization and dedusting equipment for flue gas in a kiln, which includes a process water tank 1, a process water pump 2, a primary process water flow meter 3, a Venturi section structure 4 of a defluorination tower, a leak-proof cap 5, and a waste Dust packing vehicle structure 6, defluorination tower structure 7, secondary process water flow meter 8, defluorination tower outlet flue 9, cyclone separator 10, cyclone separator outlet flue 11, discharge pipe 12, primary exhaust Smoke pipe 13, defluorination tower return chute 14, lime powder bin structure 15, primary connecting pipe 16, manual valve 17, desulfurization tower outlet flue 18, smoke outlet pipe 19, desulfurization tower Venturi section 20, desulfurization lower layer Nozzle 21, desulfurization upper nozzle 22, desulfurization tower 23, flue gas induced draft fan 24, bag filter structure 25,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com