Variable direct-current loop iron alloy ore heat stove

A DC circuit, ferroalloy technology, applied in the field of variable DC circuit ferroalloy submerged arc furnace, can solve the problems of hot anode at the end, electrode soft and hard breaking accident, rapid consumption of anode electrode, etc., so as to reduce load fluctuation and ensure reliable product quality , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

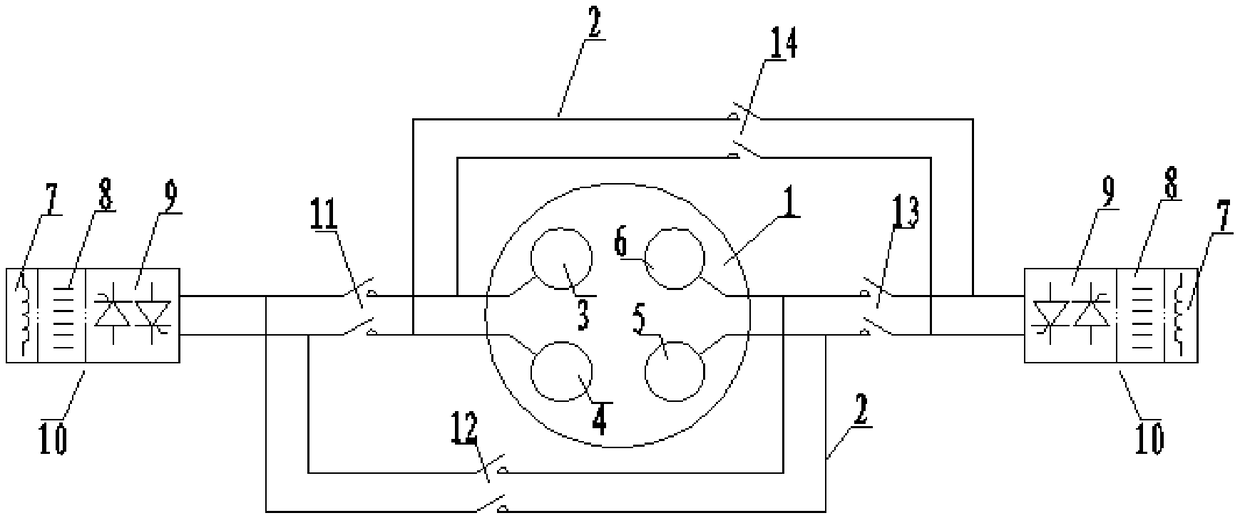

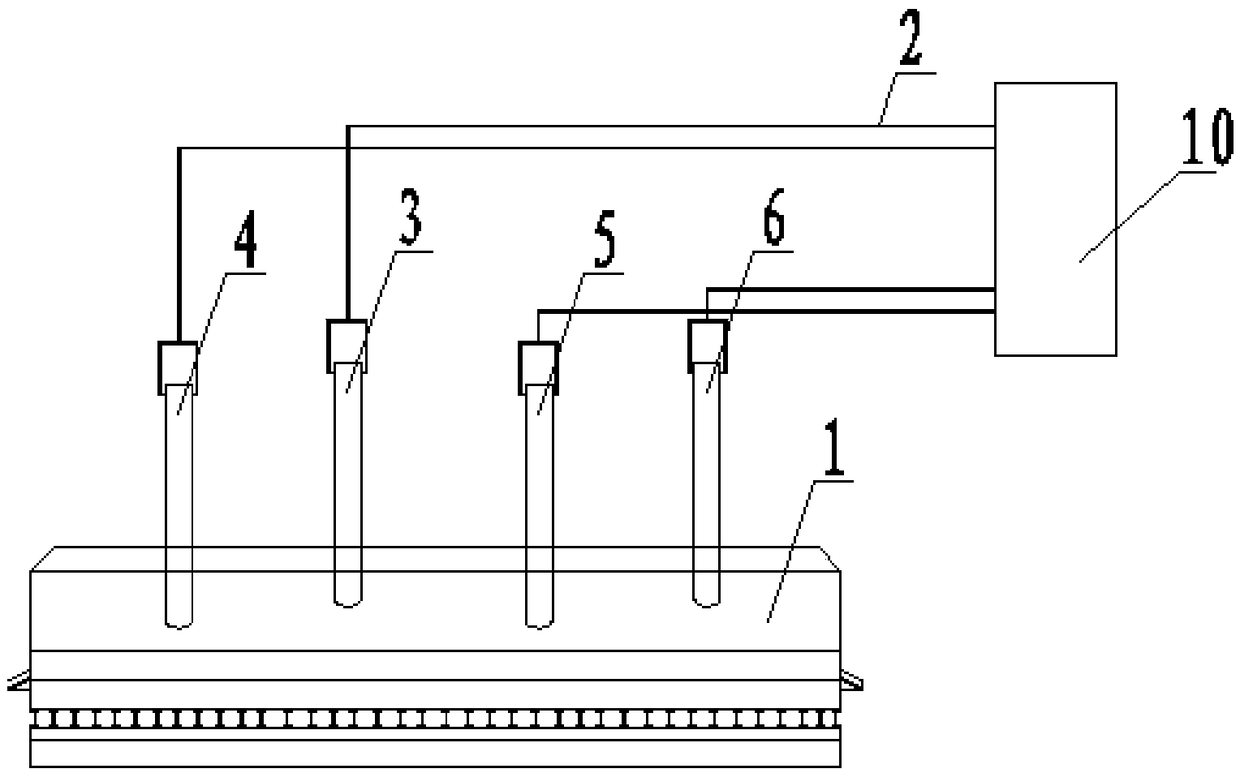

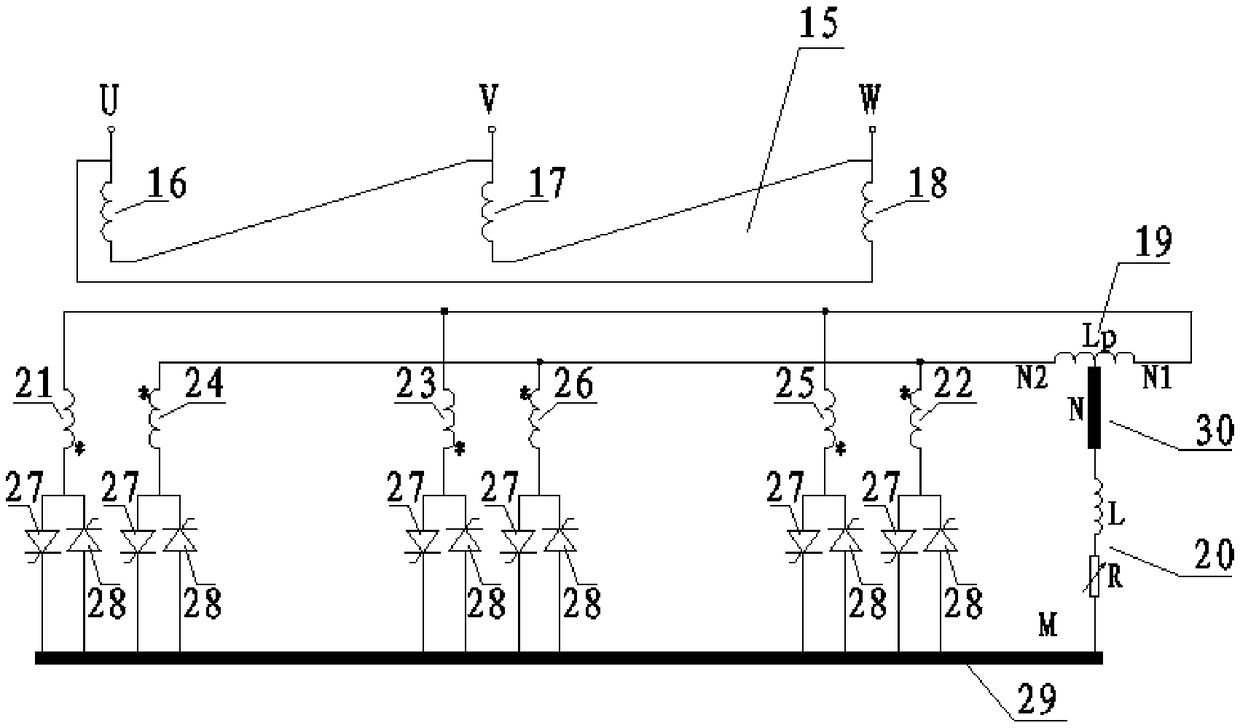

[0053] The variable direct current circuit ferroalloy submerged arc furnace provided by the present invention is based on a standard design of a double reverse star rectifier circuit with a balance reactor, and its connection mode is as follows Figure 1-2 As shown, the submerged arc furnace is mainly composed of submerged arc furnace body (1), connecting conductor (2), smelting electrode A1 (3), smelting electrode A2 (4), smelting electrode B1 (5), smelting electrode B2 (6) , a rectifying and voltage regulating power supply system (10), a DC knife switch S11 (11), a DC knife switch S12 (12), a DC knife switch S21 (13), and a DC knife switch S22 (14). Wherein, the connecting conductor (2) is mainly composed of a water-cooled copper tube, a rectangular copper plate, a copper plate soft connection, and a copper rod. The rectification and voltage regulation power supply system (10) is composed of a voltage regulation and rectification transformer (7), a connecting copper plate (8...

Embodiment 2

[0063] Embodiment 1 takes the 4-electrode circular furnace as a model, and designs the submerged arc furnace structure, such as Figure 4-8 As shown, (on the basis of Embodiment 1), the present invention also provides several other forms of electrode distribution that are also applicable to the present invention. Figure 4 It is the floor plan of the variable DC circuit 6-electrode rectangular submerged arc furnace, Figure 5 It is the floor plan of the variable DC circuit 6-electrode circular submerged arc furnace, Figure 6 Layout plan of variable DC circuit 6-electrode ultra-high power rectangular submerged arc furnace, Figure 7 Layout plan of 8-electrode rectangular submerged arc furnace with variable DC circuit, Figure 8 It is a plan layout of a 10-electrode rectangular submerged arc furnace with a variable DC circuit. The above-mentioned electrode arrangement methods all follow the distribution rule of smelting electrodes with opposite polarity around any electrode....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com