Patents

Literature

32results about How to "Reliable product quality guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

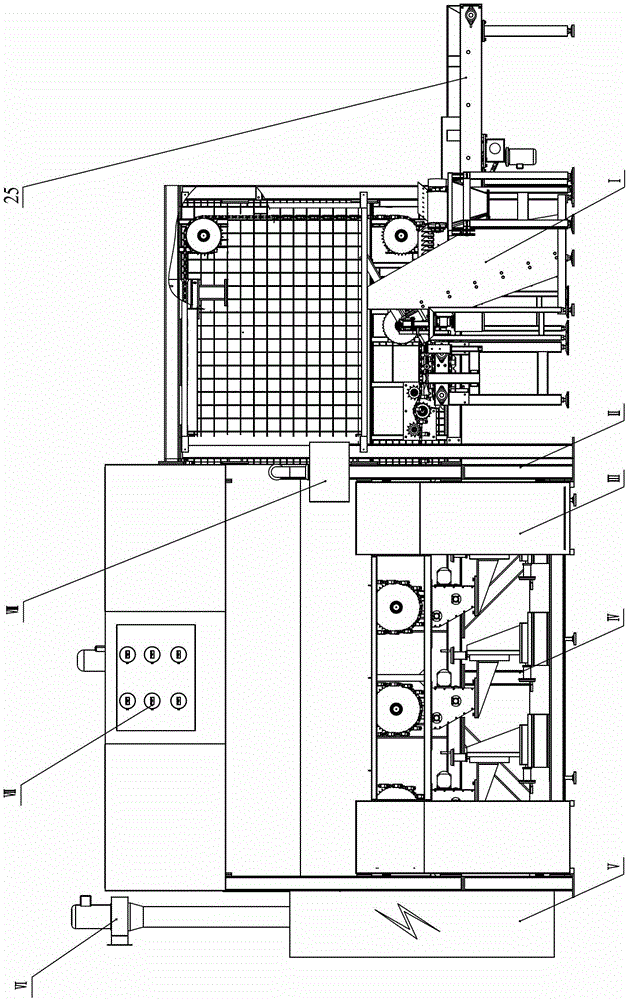

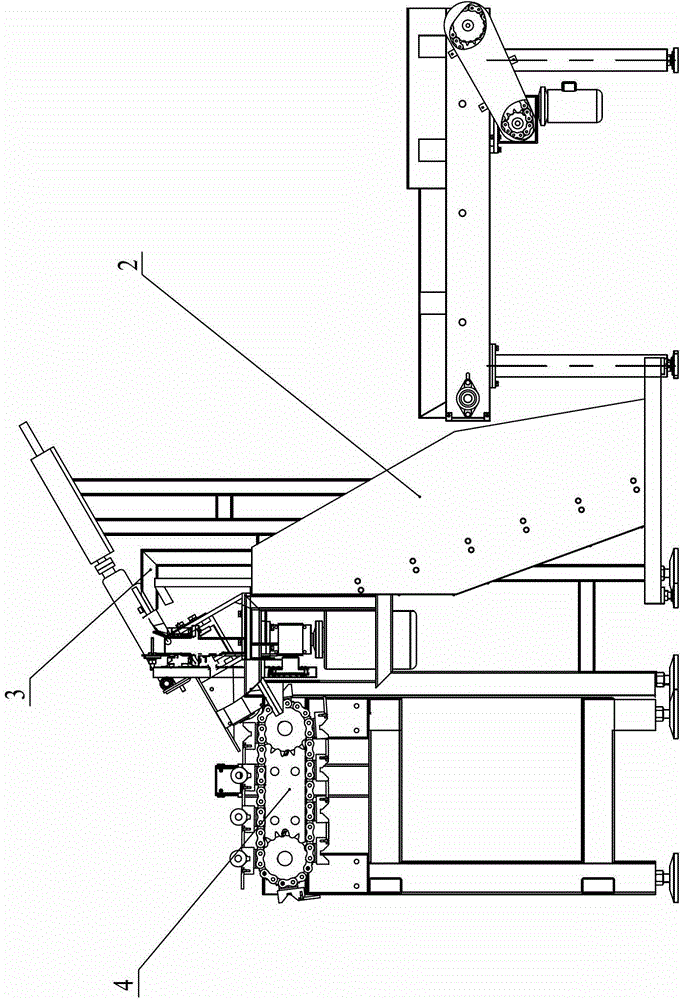

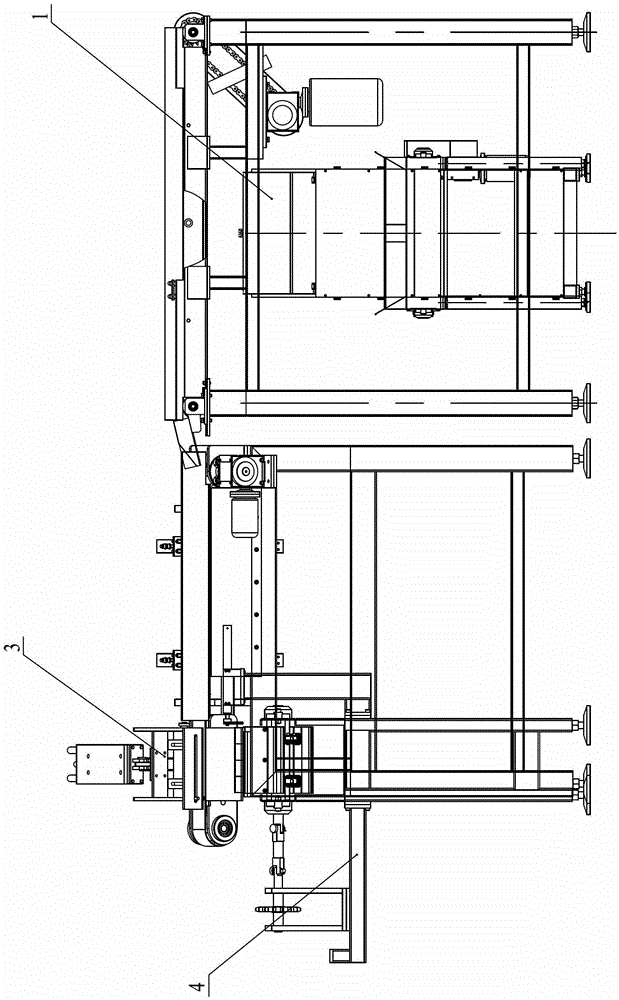

Roller coating machine

ActiveCN102974498ASolve Adhesion ProblemsSolve for uniformityPretreated surfacesCoatingsMachineIndustrial engineering

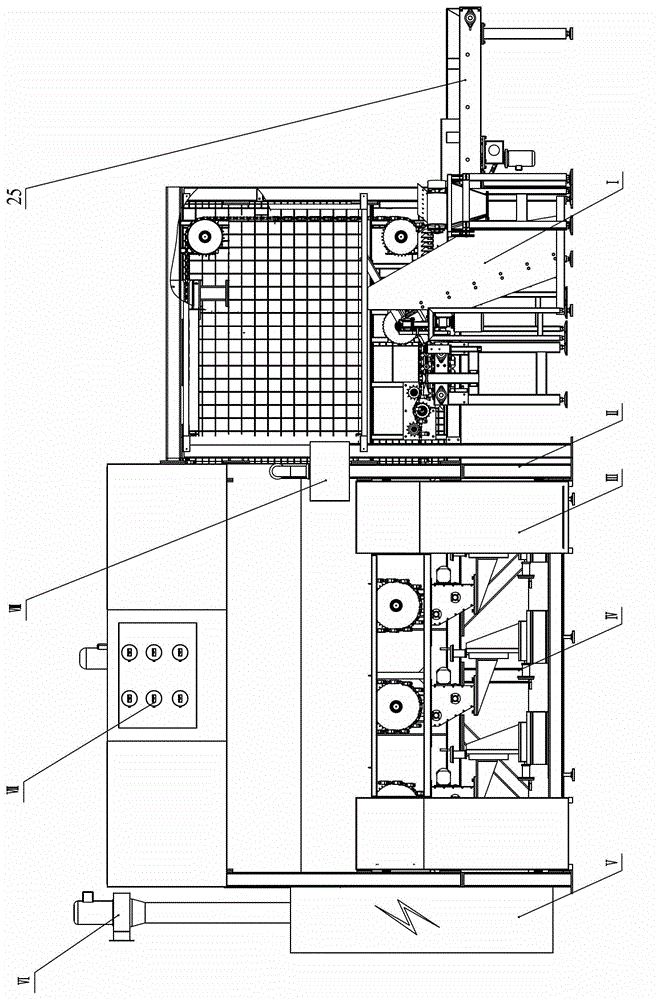

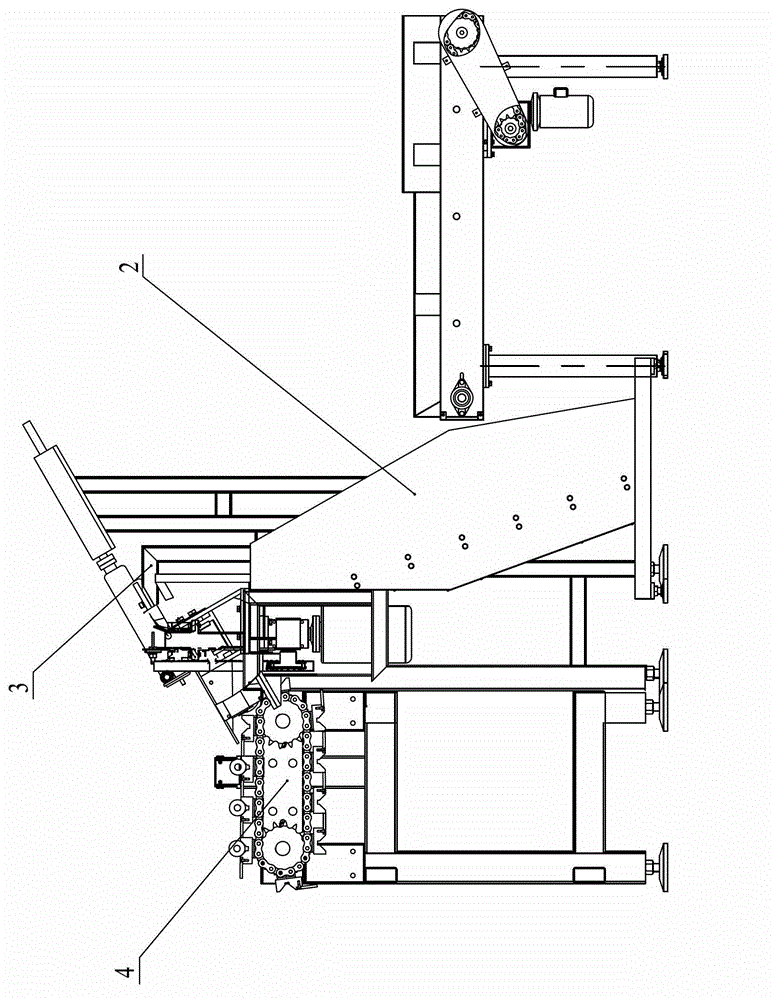

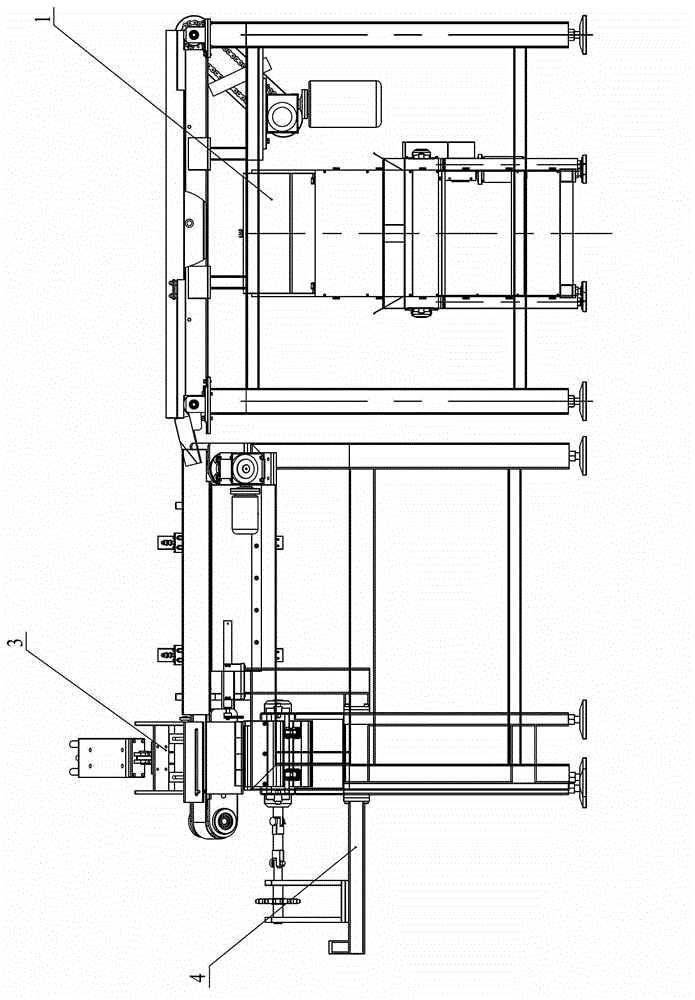

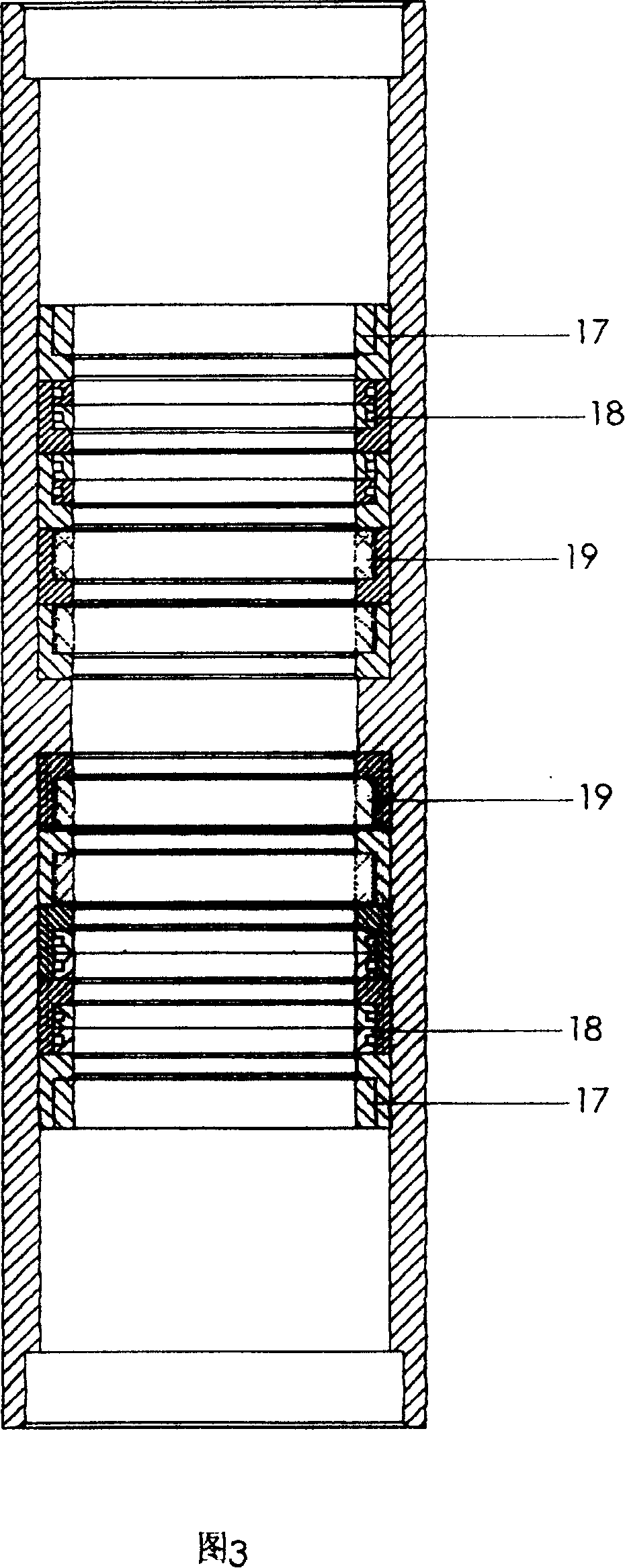

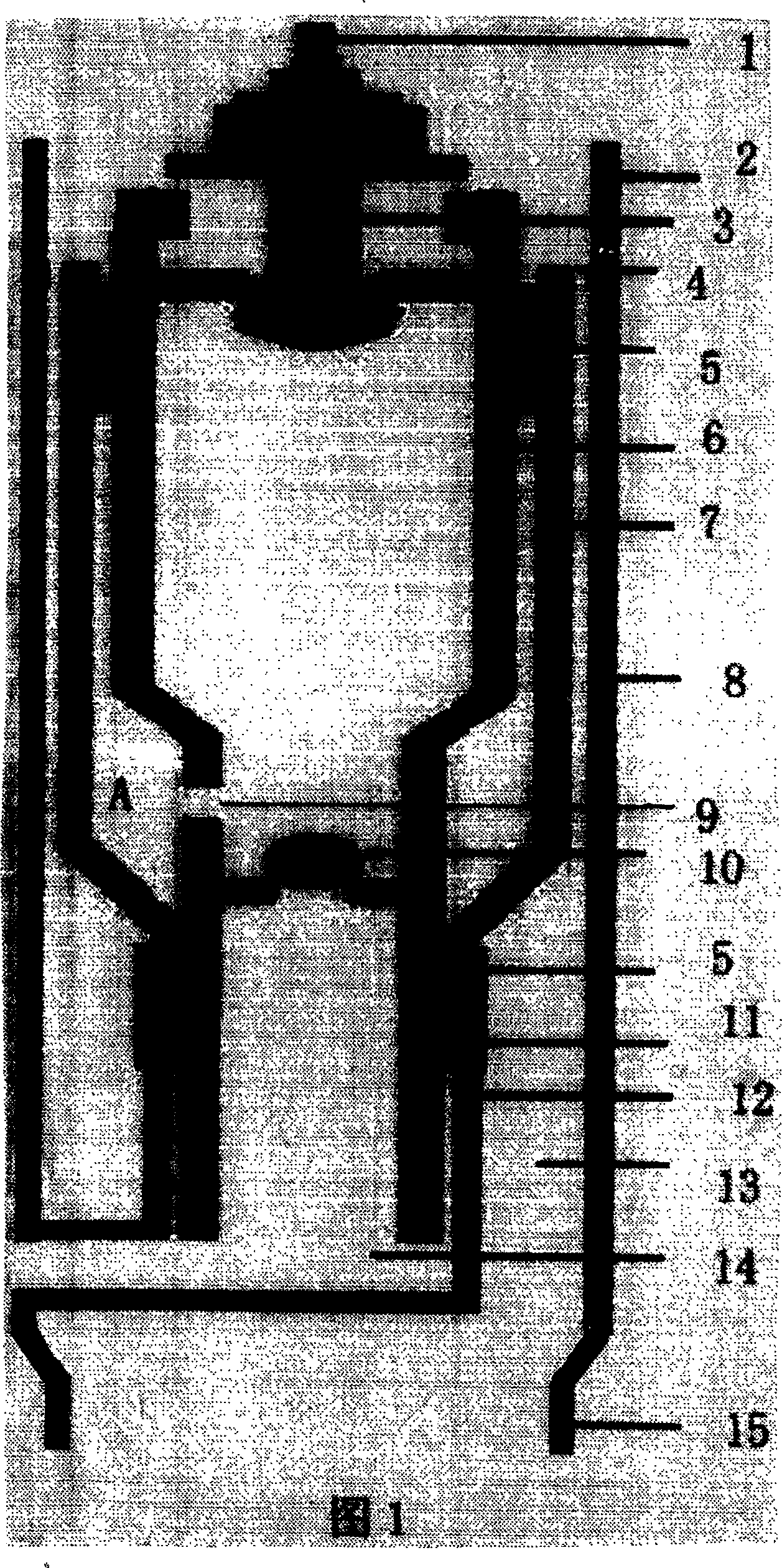

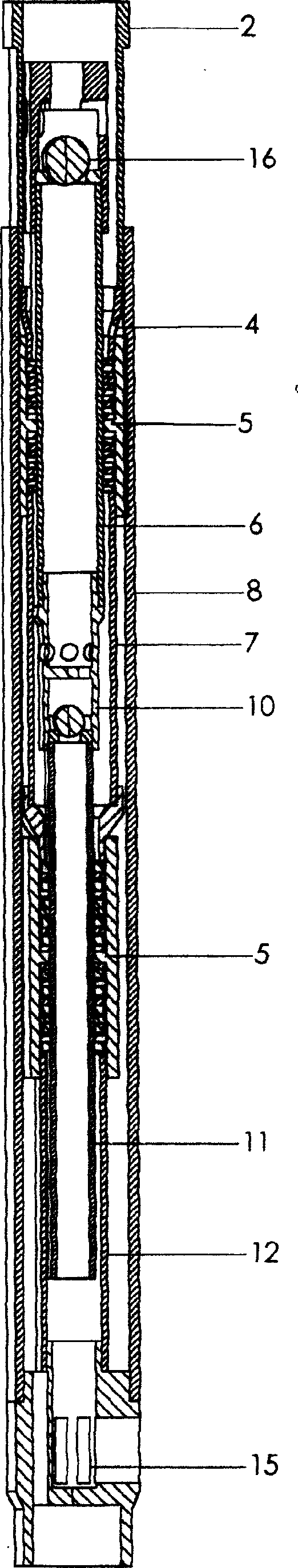

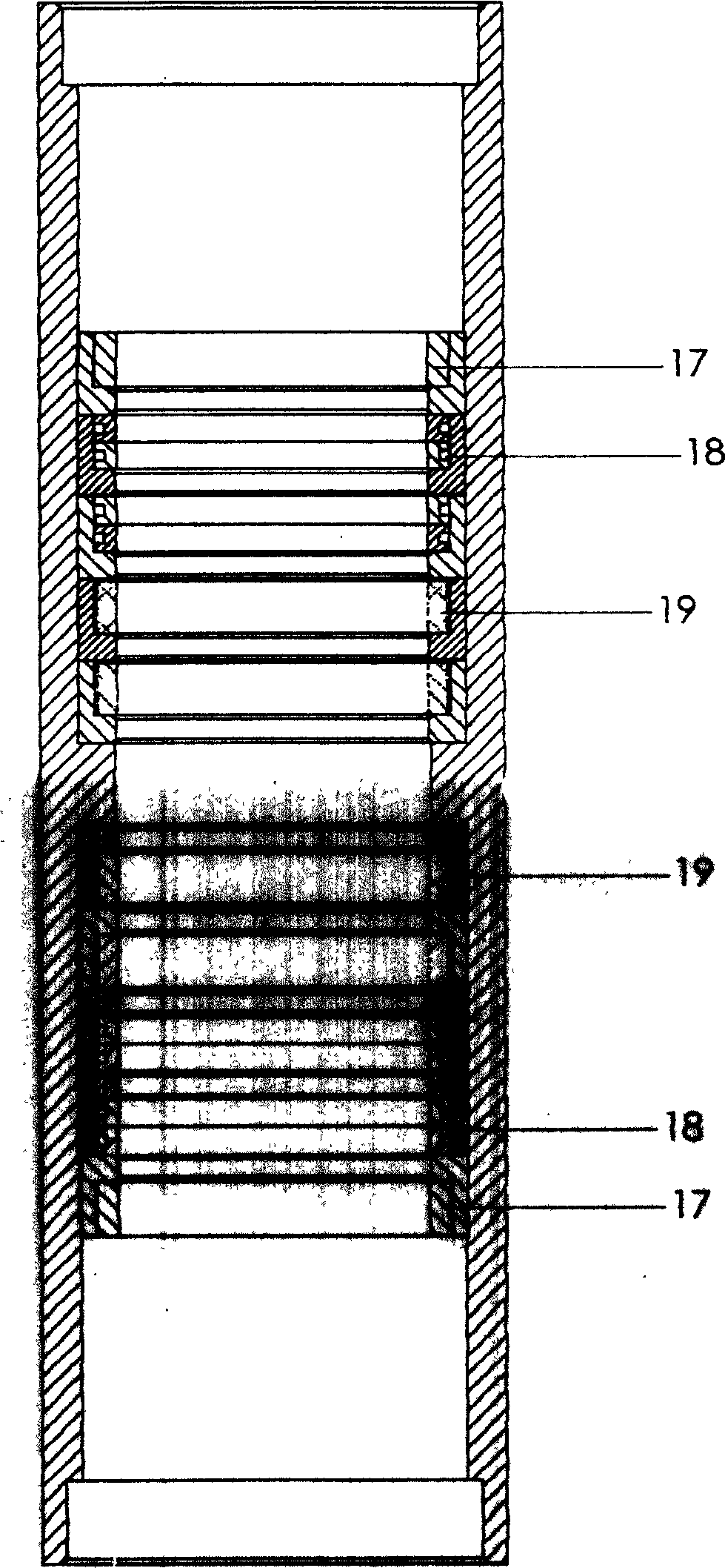

The invention relates to a roller coating machine. Workpieces needing to be coated are pushed into a material turnover frame of a material turnover mechanism; the material turnover mechanism rotates the material turnover frame; the workpieces are turned and are poured into a material blocking hopper; the workpieces are conveyed to a material storage hopper of a discharge mechanism by a discharge conveying machine; the workpieces are lifted by the discharge mechanism, then are arranged in order and roll into a vibration transmission rack according to a certain rule; the workpieces are conveyed to a synchronous material-pushing mechanism; the workpieces arranged tidily are pushed to a V-shaped groove of a synchronous material-loading mechanism by the synchronous material-pushing mechanism; the workpieces are subjected to position adjustment by the synchronous material-loading mechanism and then are pushed to a material hanging mechanism on a workpiece transmission rack; the material hanging mechanism drives the workpieces and feeds them into an automatic glue-rolling device; a glue liquid is uniformly roll-coated on the surfaces of the workpieces by the automatic glue-rolling device; the workpieces coated with the glue liquid are fed to an unloading mechanism by the workpiece transmission rack; and the workpieces coated with the glue liquid are fed to a material receiving hopper by the unloading mechanism, then are fed into a workpiece delivery wagon and then are output. The roller coating machine adopts a roll-coating technology to realize workpiece surface treatment, is efficient, saves energy, is environmentally friendly and is suitable for large-scale glue-rolling of tubular workpieces.

Owner:WUXI HUANENG SURFACE TREATMENT

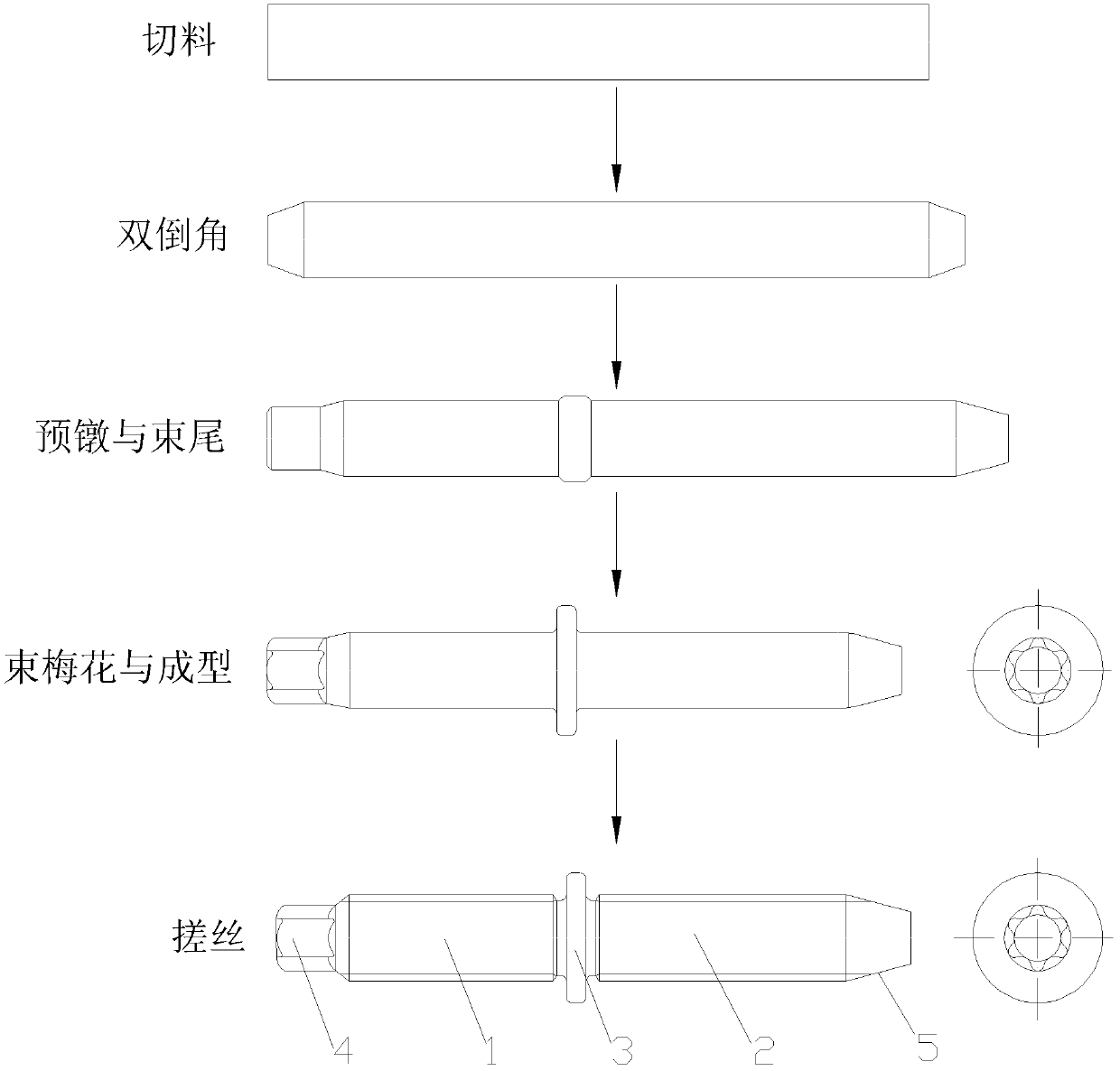

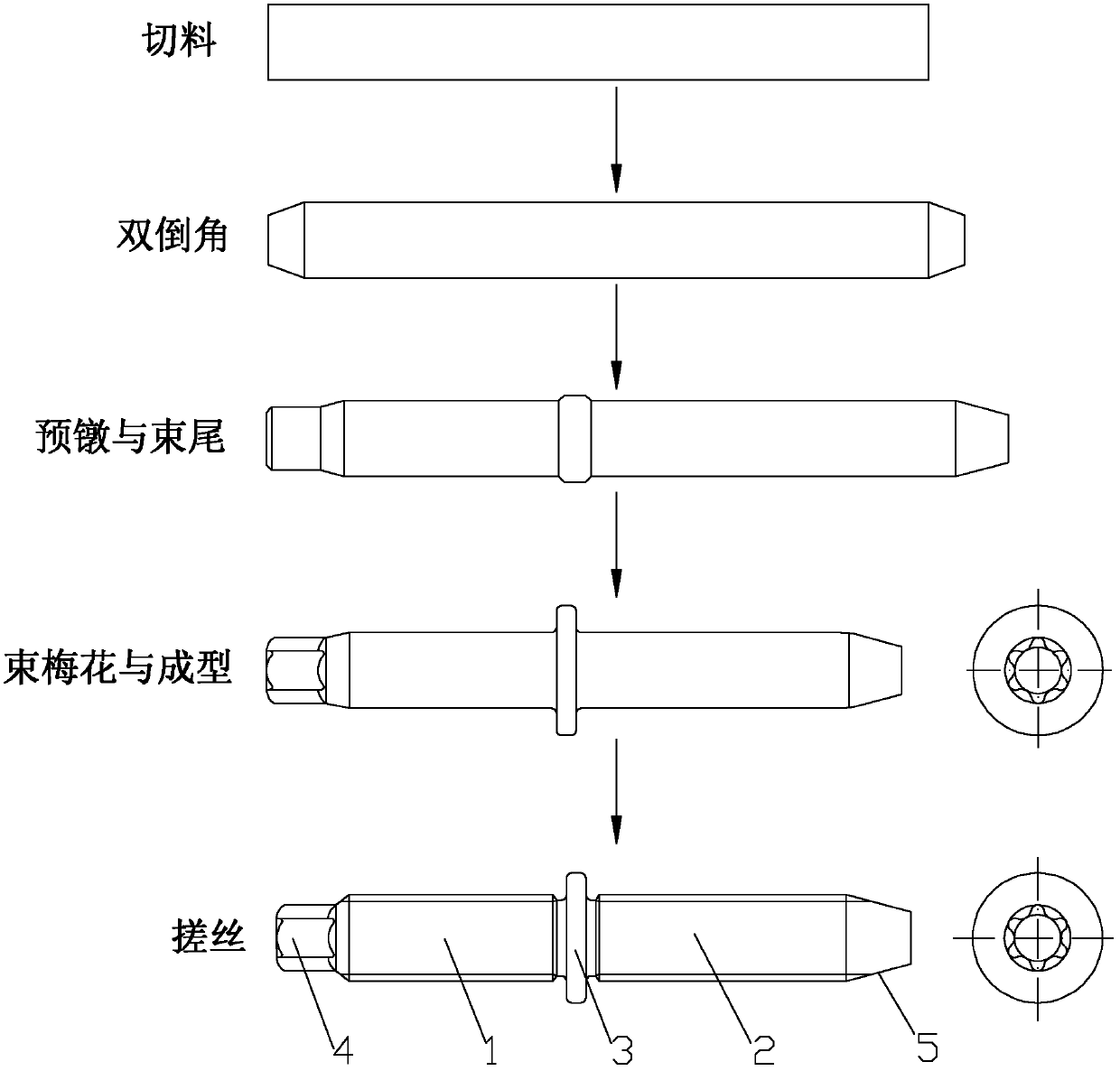

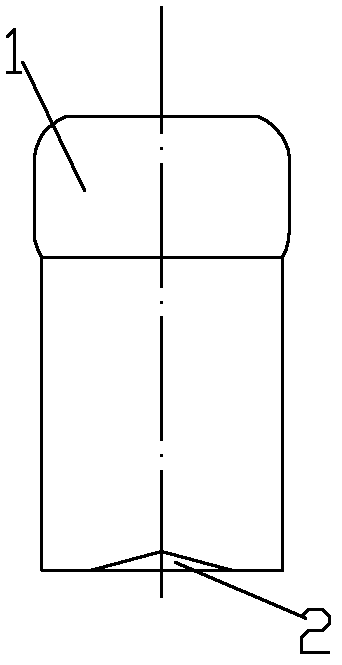

Process for manufacturing quincuncial dowel screws

InactiveCN102601589AReduce labor intensityImprove efficiencyMetal-working apparatusQuincunxMachining process

The invention discloses process for manufacturing quincuncial dowel screws. The process mainly includes steps: (1) cutting; (2), double chamfering; (3) preliminary heading and tail binding; (4) quincunx binding and forming; (5) thread rolling; (6) heat treatment; and (7) surface treatment. The process for manufacturing quincuncial dowel screws has the advantages that an integral processing procedure is divided into a plurality of working procedures, a blank is in cold heading processing to form a product, generated waste materials are avoided in the processing procedure, processing speed and efficiency are high, cost is effectively controlled, labor intensity of personnel is reduced, and the quality of the product can be reliably guaranteed.

Owner:苏州新凌电炉有限公司

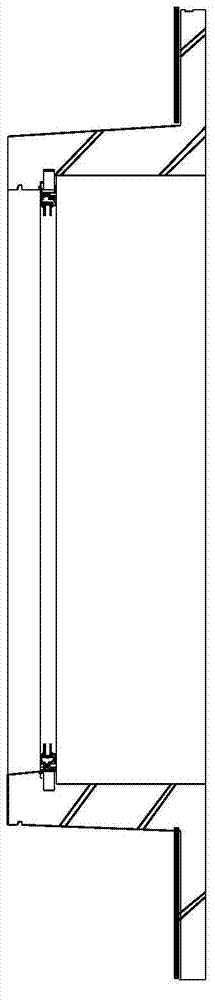

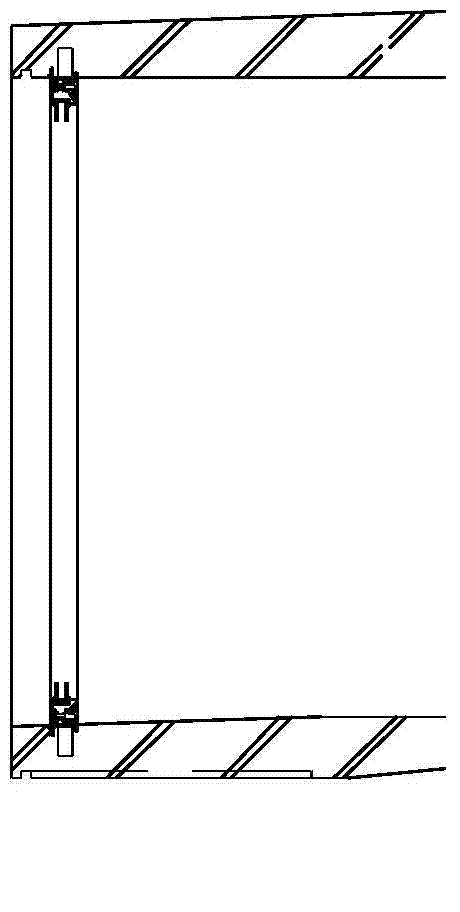

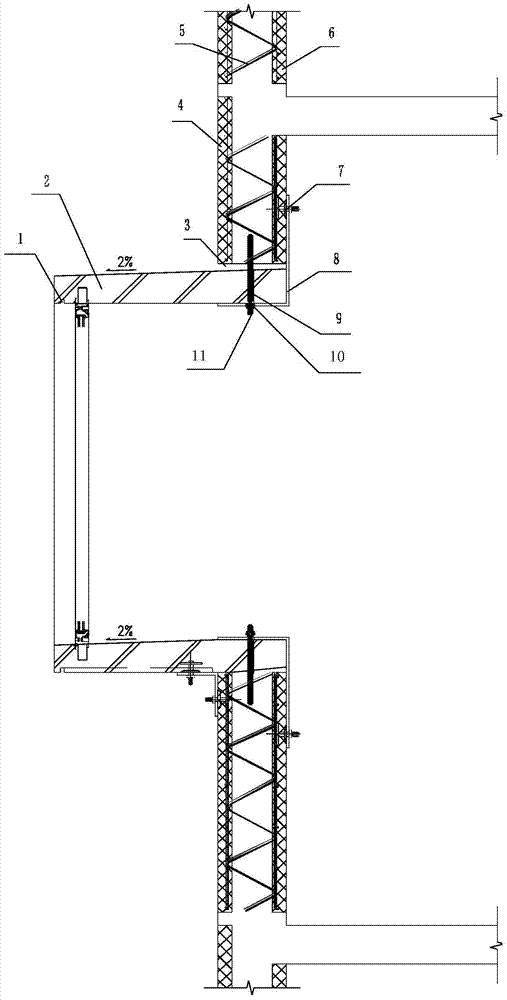

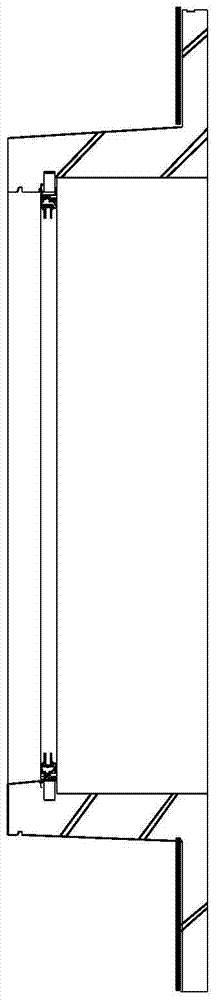

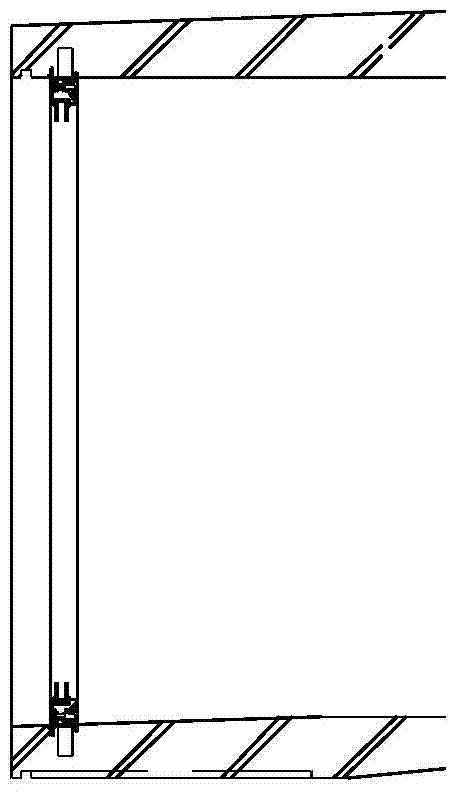

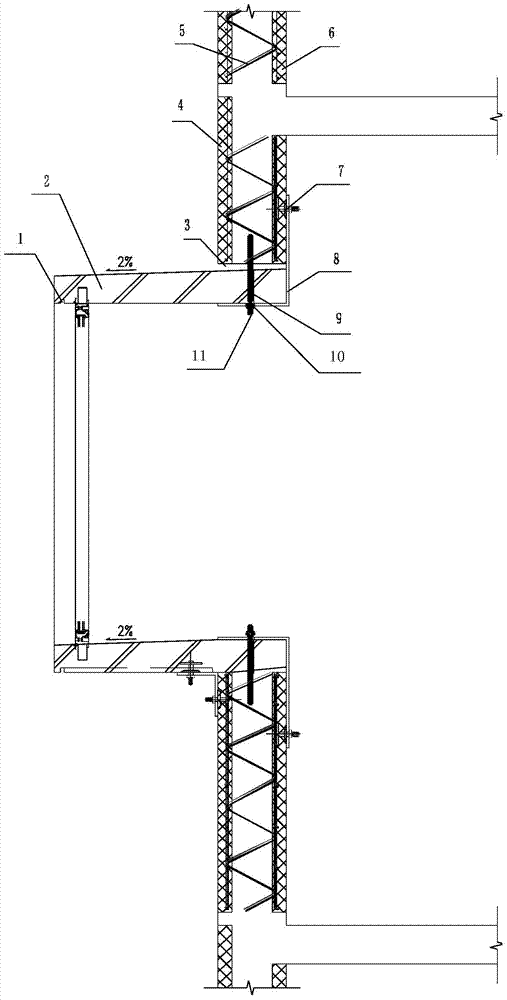

Prefabricated bay window structure installed on laminated wall board and installing method

The invention relates to the window installing technology in the building field, in particular to a prefabricated bay window structure installed on a laminated wall board. A prefabricated bay window (2) is composed of an upper eave, a lower eave, a left vertical face and a right vertical face of the prefabricated cement board bay window, and embedded screw tubes (9) or nuts (7) are arranged at the corresponding joints of the periphery of the prefabricated bay window (2) and the laminated wall board. An installing method of the prefabricated bay window comprises the steps that firstly, a rectangular frame is formed; secondly, the nuts (7) are embedded; thirdly, the prefabricated bay window (2) is inserted and is flush with the inner wall of the laminated wall board; fourthly, a plurality of pieces of L-shaped angle iron (8) are prepared; fifthly, the inequilateral L-shaped angle iron (8) is arranged on the inner wall, and long screw rods (11) are screwed in the embedded screw tubes (9) through nuts; sixthly, the equilateral L-shaped angle iron (8) is arranged on the outer wall; seventhly, caulking is carried out through mortar (3) for blockage, and concrete is poured in a middle cast-in-place layer of the laminated wall board. The prefabricated bay window is not provided with an outer folded edge, the occupied space is small, manufacturing, storing and transporting are very easy and convenient, the prefabricated bay window structure is suitable for building window frame and laminated wall board factory-like line production, field assembling is easy, the construction speed is increased, the work period is shortened, the construction quality is high, and cost is saved.

Owner:BAOYE GROUP CO LTD +1

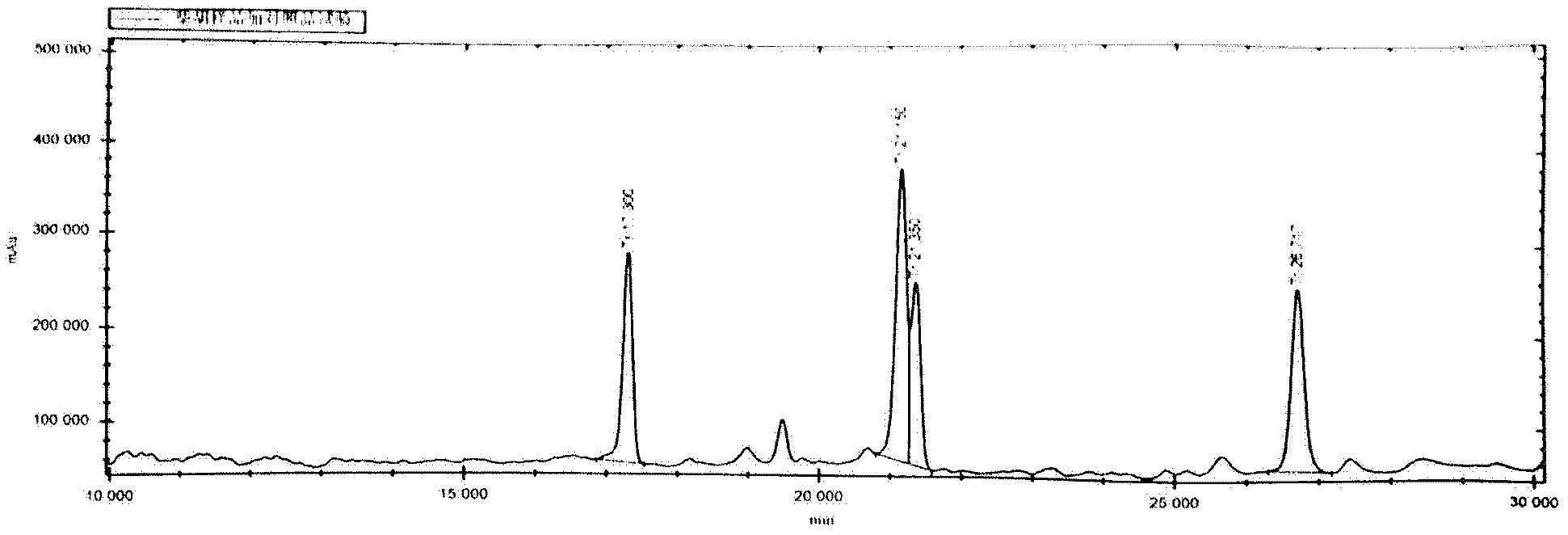

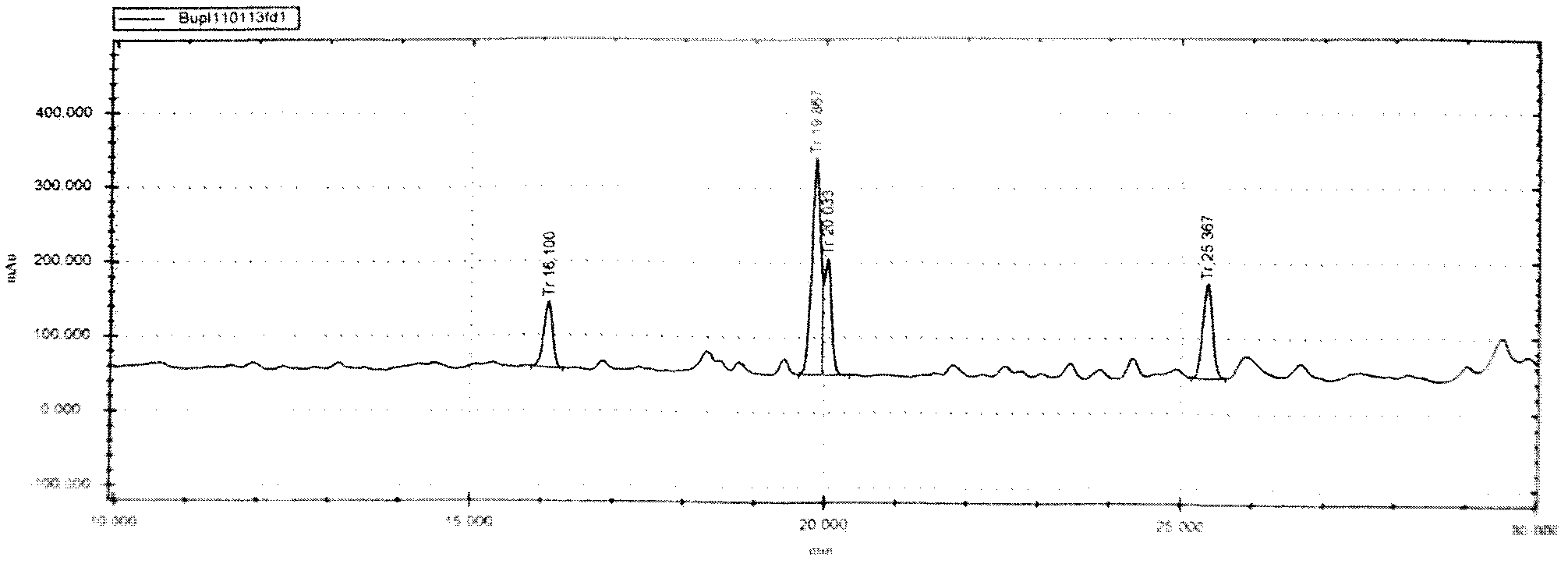

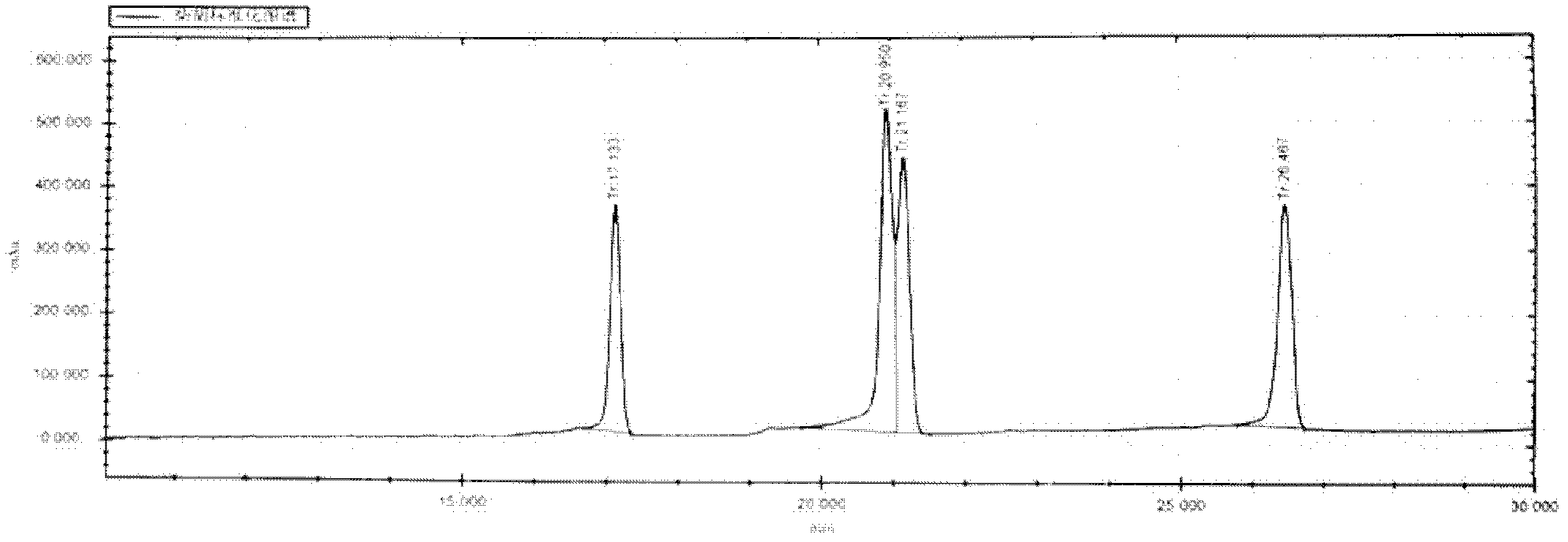

Quality standard of standardized bupleurum extract

InactiveCN102565272AUniform qualityQuality is easy to controlComponent separationExperimental researchMedicine

The invention relates to a method for controlling the quality of a standardized extract of a Chinese herbal medicine, i.e., the quality standard of standardized bupleurum extract. The method comprises the following steps: the bupleurum chinense is extracted in the semi-bionic environment, the total content of the main effective components (saikosaponin a, saikosaponin b, saikosaponin c and saikosaponin d) of the extract is equal to or greater than 1.874 percent, and the total content is equal to or greater than 1.3 percent according to the standard content index. The quality standard of the standardized bupleurum extract includes identification of bupleurum extract, content determination of saikosaponins, specific chromatogram determination and other detection items. The main components of the bupleurum extract can be determined qualitatively and quantitatively, the unified and controllable quality and the standardize production of the bupleurum extract can be ensured, the pharmaceutical quality and the therapeutic effect of the bupleurum extract are guaranteed, and a new quality standard is formulated for completely and accurately evaluating the quality of the standardized bupleurum extract on the basis of experimental research. The method has the characteristics of simplicity, convenience, stability and good reproducibility, and is favorable for improving the inspection efficiency.

Owner:吉林人参研究院

Healthcare wine for fortifying kidney and strengthening the male function and its preparation method

InactiveCN1481852ACompatibility and prescription scienceGood effectDigestive systemAlcoholic beverage preparationEpimediumRehmannia glutinosa

The tonic wine with the functions of invigorating kidney, producing life essence and strengthening Yang is prepared with spirit and ten kinds of Chinese medicinal materials including angelica, epimedium, desert cistanche, gecko, prepared rhizome of rehmannia, etc. It has obvious effects and mild cost.

Owner:郭志忠

Health tea for resisting anxiety, relieving depression and improving sleep

InactiveCN101569338AFormulation ScienceGood effectTea substituesFood preparationGastrodiaSide effect

The invention provides health tea for resisting anxiety, relieving depression and improving sleep, which is characterized by comprising the following compositions by weight percentage: 10 to 30 percent of spina date seed, 5 to 20 percent of platycladi seed, 10 to 40 percent of thinleaf milkwort root-bark, 10 to 20 percent of red sage root, 5 to 20 percent of szechwon tangshen root, 5 to 20 percent of tall gastrodia tuber, 10 to 30 percent of manyflower solomonseal rhizome, 5 to 20 percent of hawthorn, 5 to 20 percent of medlar and 5 to 20 percent of Indian buead. The health tea has the advantages of scientific formula, obvious effect, convenient drinking and no side effect, and achieves the diet therapy effect beneficial for health in a tea drinking mode by calming heart and nerves.

Owner:郭志忠

Food-cure medicated wine which can cure bone arthralgia and preparation method

InactiveCN1481853ACompatibility and prescription scienceGood effectAntipyreticAnalgesicsJoint arthralgiaRhizome

The tonic wine for treating bony arthralgia is prepared with spirit and 11 kinds of Chinese medicinal materials including dahurian angelica root, Sichuan achyranthes root, angelica, eucommia bark, lesser galangal rhizome, etc. It has obvious effects and mild cost.

Owner:郭志忠

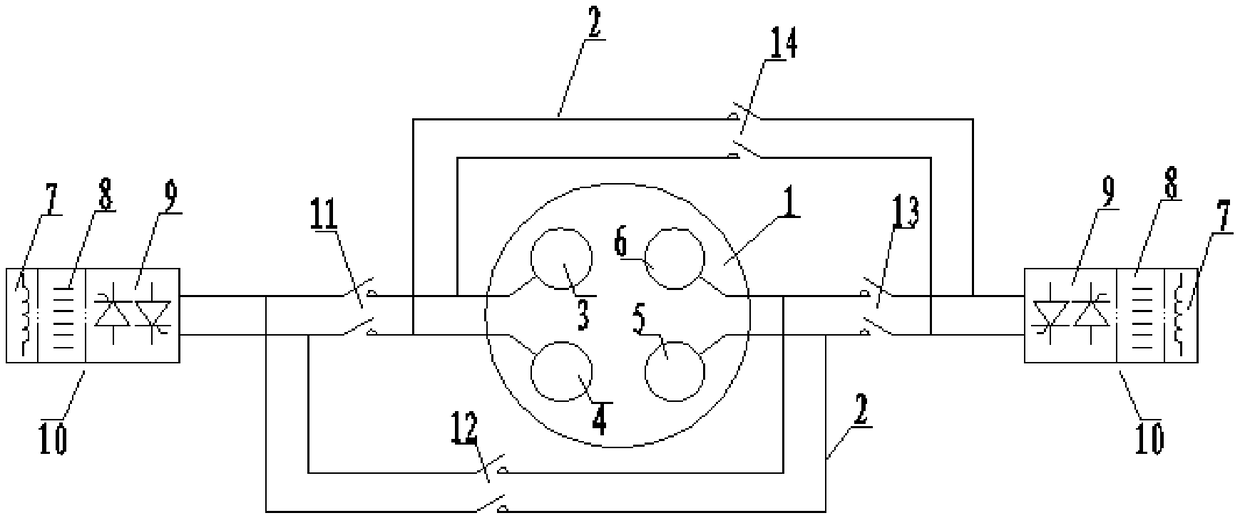

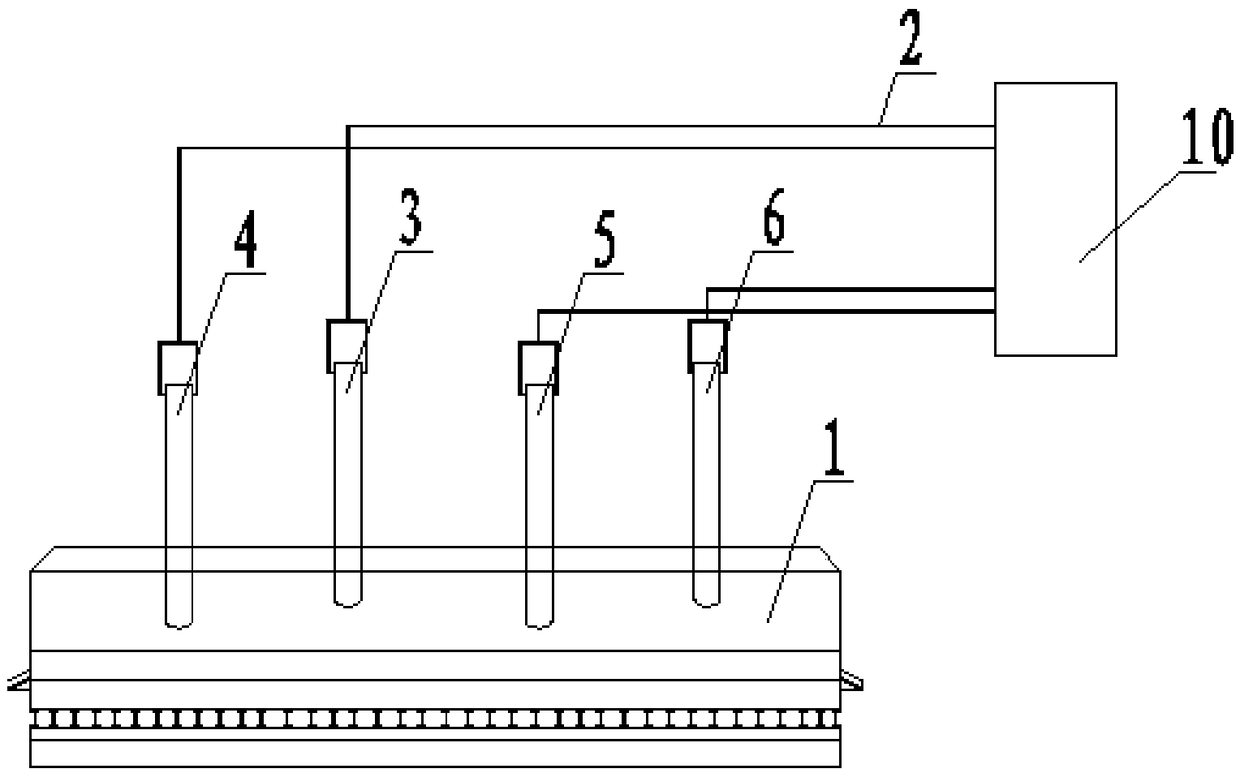

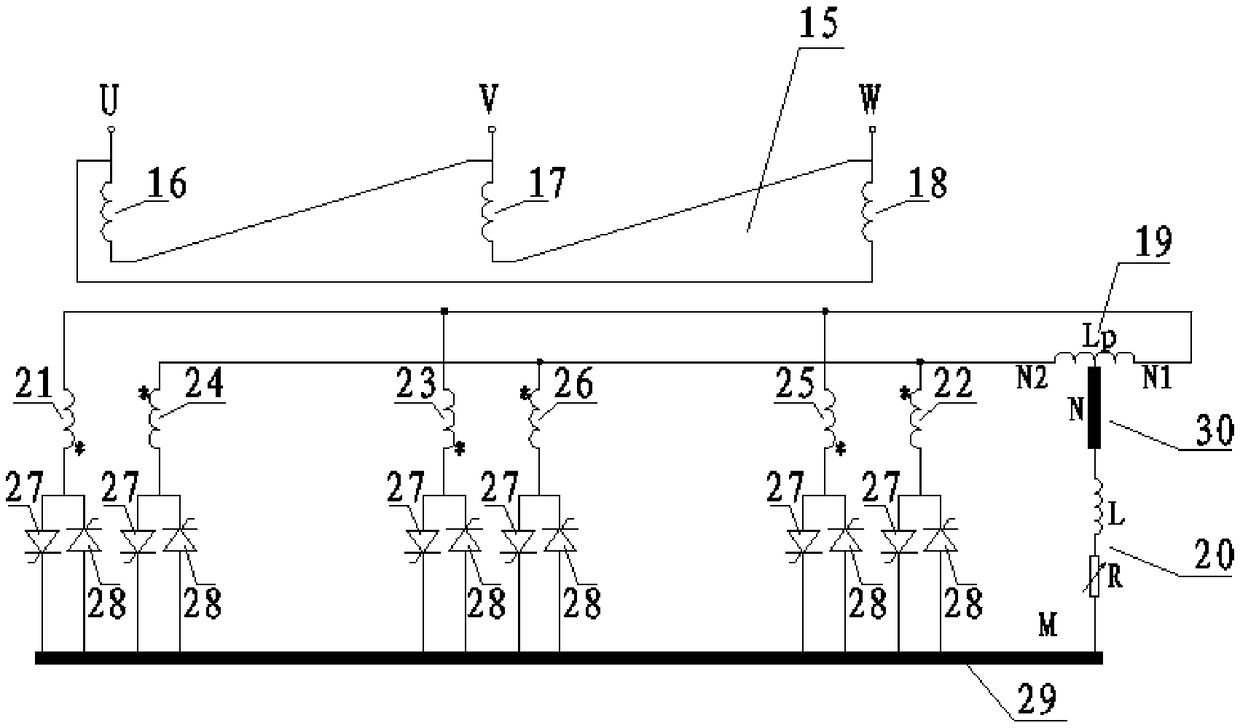

Variable direct-current loop iron alloy ore heat stove

ActiveCN109000481AAvoid or reduce electrode disconnection accidentsGuaranteed smooth productionIncreasing energy efficiencyCrucible furnacesElectrical conductorControl objective

The invention provides a variable direct-current loop iron alloy ore heat stove. The variable direct-current loop iron alloy ore heat stove mainly comprises an ore heat stove body, N sets of rectifying voltage-regulating power supply systems, and a redundant mutually-backup group, wherein N pairs of smelting electrodes extend into the ore heat stove body for heating, melting and smelting cores; the N sets of rectifying voltage-regulating power supply systems are connected with the smelting electrodes for separately controlling polarity switching of the smelting electrodes; the redundant mutually-backup group is arranged on a connecting conductor for converting control objectives of each set of the rectifying voltage-regulating power supply systems. When the variable direct-current loop iron alloy ore heat stove works, N sets of the rectifying voltage-regulating power supply systems separately control polarity switching of N pairs of the smelting electrodes to realize uniform roasting of each pair of smelting electrodes. The technical scheme adopted by the invention solves the problem that accidents such as electrode breakage in a production process due to the fact that roasting forpositive and negative electrodes is out of step in the prior art.

Owner:大连重工机电设备成套有限公司 +1

Method for removal of RH vacuum chamber bottom channel steel slag

The invention provides a method for removal of RH vacuum chamber bottom channel steel slag. Heat release of an aluminum oxygen reaction process is utilized to perform melting removal on steel slag. The method consists of: preheating: controlling an oxygen lance's position at 5000-5600mm and the gas flow at 400-500m<3> / h, performing baking for 10-20min until steel slag begins to drip at a bottom channel, then raising the ascending gas flow to 120-150m<3> / h; aluminum adding: using an aluminum alloy hopper to add 100-200kg of aluminum wire segment to the vacuum chamber bottom channel position; and slag melting: controlling the oxygen lance's position at 5000-5600mm and the gas flow at 400-600m<3> / h, further performing baking for 5-20min until the aluminum wire segment added into the bottom channel burns and the steel slag melts, and at the end of the aluminum wire segment reaction, adjusting the ascending gas flow to 80-120m<3> / h. The method provided by the invention can realize online removal of bonded steel slag at the bottom of the RH vacuum chamber bottom channel, thereby effectively reducing the RH circulating pipe hang slag, expanding the circulation pipe inner diameter, increasing the RH molten steel circulation velocity, and ensuring the product quality reliable guarantee.

Owner:ANGANG STEEL CO LTD

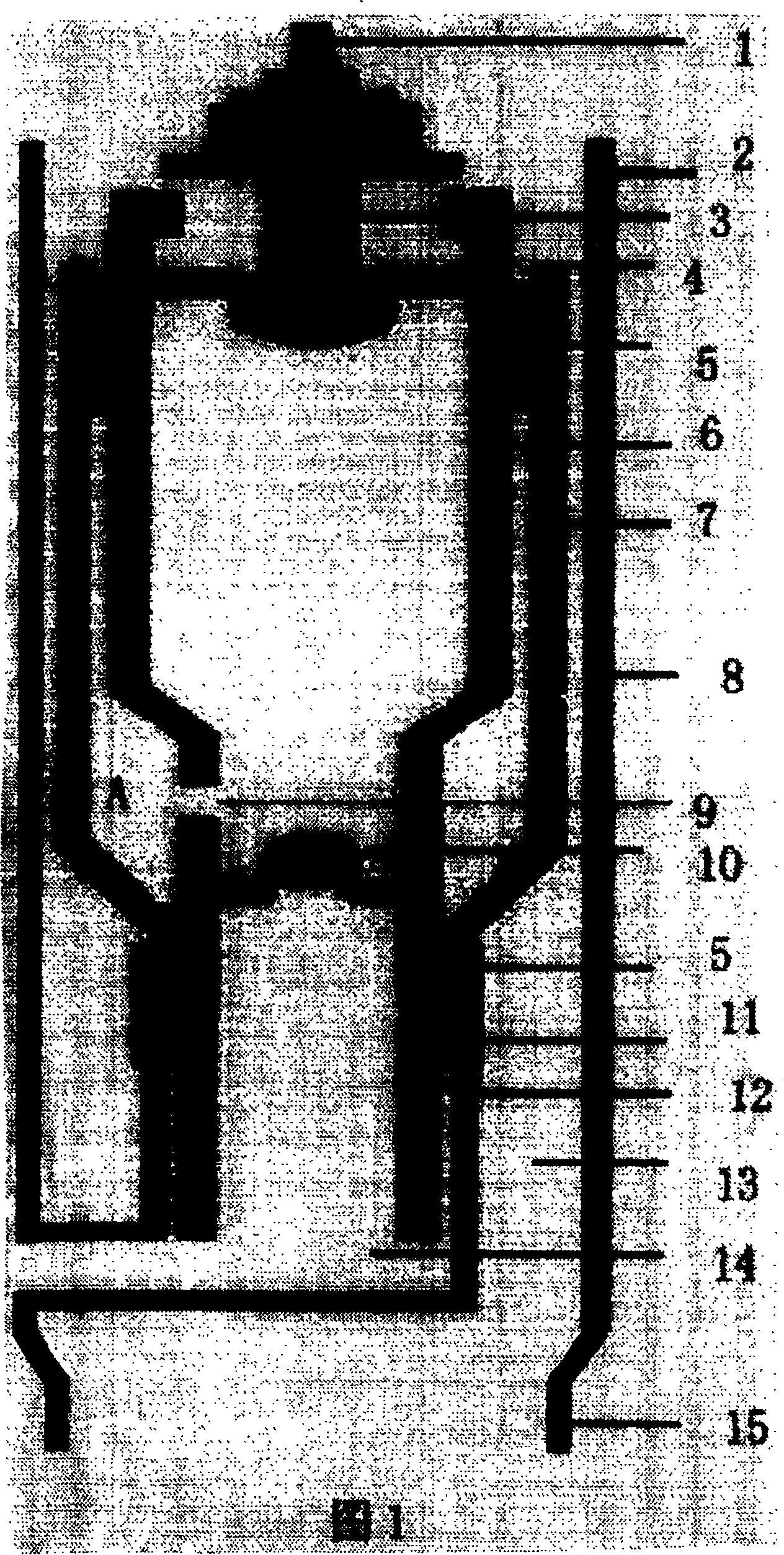

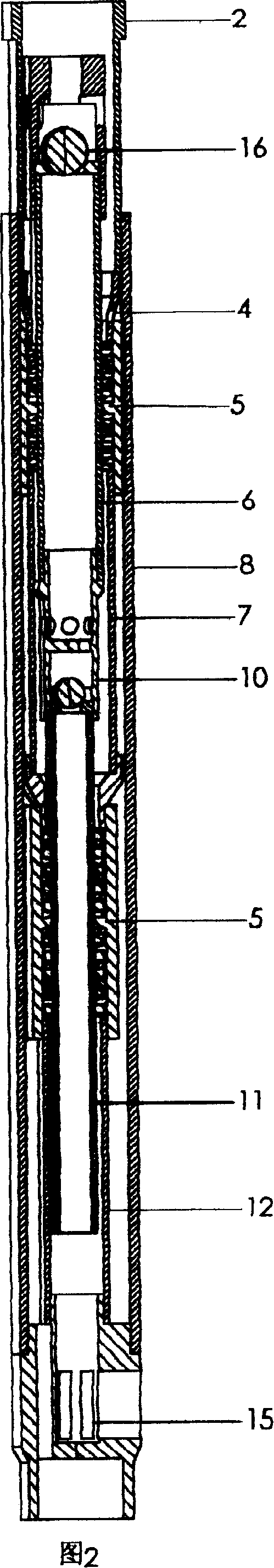

Strong anti-thickening anti-sand hydraulic feedback oil pump with long plug ring seal and oil inlet sand deposition path

InactiveCN100376794CImprove sealingHigh pump efficiency and long cyclePositive displacement pump componentsFlexible member pumpsEngineeringPumpjack

The invention relates to a kind of hydraulic feedback oil-well pump with a long round plug and passageways for oil-entering and sand-depositing, strong guard against dense and, includes sealing total five and double passageways structure of oil-entering and sand-deposition. The trait of the pump is fixing a long plug sealing system between shaft-plug and tube, and fixing a passageway structure of oil-entering and sand-depositing between pump tube and tube outside. This equipment is used to enhance the usefulness of the pump, enhance the function avoiding dense and sand, prolong the using life. The invention has reasonable design, simple structure, easy-making, and convenient-using, efficient and good sealing function; entering passage is separated from depositing passageway, not gather in the tube as the routine pump do, the oil tube pole avoids buried by sand, Even if under the condition that oil is buried in sand, the pump can also produce with sand. The life span of this pump is three to five times more than the routine one.

Owner:陈世家

Strong anti-thickening anti-sand hydraulic feedback oil pump with long plug ring seal and oil inlet sand deposition path

InactiveCN1587709AImprove sealingHigh pump efficiency and long cyclePositive displacement pump componentsFlexible member pumpsEngineeringPumpjack

The invention relates to a kind of hydraulic feedback oil-well pump with a long round plug and passageways for oil-entering and sand-depositing, strong guard against dense and, includes sealing total five and double passageways structure of oil-entering and sand-deposition. The trait of the pump is fixing a long plug sealing system between shaft-plug and tube, and fixing a passageway structure of oil-entering and sand-depositing between pump tube and tube outside. This equipment is used to enhance the usefulness of the pump, enhance the function avoiding dense and sand, prolong the using life. The invention has reasonable design, simple structure, easy-making, and convenient-using, efficient and good sealing function; entering passage is separated from depositing passageway, not gather in the tube as the routine pump do, the oil tube pole avoids buried by sand, Even if under the condition that oil is buried in sand, the pump can also produce with sand. The life span of this pump is three to five times more than the routine one.

Owner:陈世家

A method for removing channel steel slag at the bottom of rh vacuum chamber

The invention provides a method for removal of RH vacuum chamber bottom channel steel slag. Heat release of an aluminum oxygen reaction process is utilized to perform melting removal on steel slag. The method consists of: preheating: controlling an oxygen lance's position at 5000-5600mm and the gas flow at 400-500m<3> / h, performing baking for 10-20min until steel slag begins to drip at a bottom channel, then raising the ascending gas flow to 120-150m<3> / h; aluminum adding: using an aluminum alloy hopper to add 100-200kg of aluminum wire segment to the vacuum chamber bottom channel position; and slag melting: controlling the oxygen lance's position at 5000-5600mm and the gas flow at 400-600m<3> / h, further performing baking for 5-20min until the aluminum wire segment added into the bottom channel burns and the steel slag melts, and at the end of the aluminum wire segment reaction, adjusting the ascending gas flow to 80-120m<3> / h. The method provided by the invention can realize online removal of bonded steel slag at the bottom of the RH vacuum chamber bottom channel, thereby effectively reducing the RH circulating pipe hang slag, expanding the circulation pipe inner diameter, increasing the RH molten steel circulation velocity, and ensuring the product quality reliable guarantee.

Owner:ANGANG STEEL CO LTD

Manufacturing process of screw nut

The invention discloses a manufacturing process of a screw nut. The manufacturing process comprises the following steps of (1) cutting, (2) preliminary upsetting, (3) perforating, and (4) final upsetting and forming. According to the manufacturing process of the screw nut, the entire machining process is divided into multiple steps, a blank is stamped to form a product, no waste is produced, the machining speed and the machining efficiency are high, the cost is effectively controlled, the labor intensity of workers can be alleviated, and the product quality can be reliably guaranteed.

Owner:苏州新凌高强度紧固件有限公司

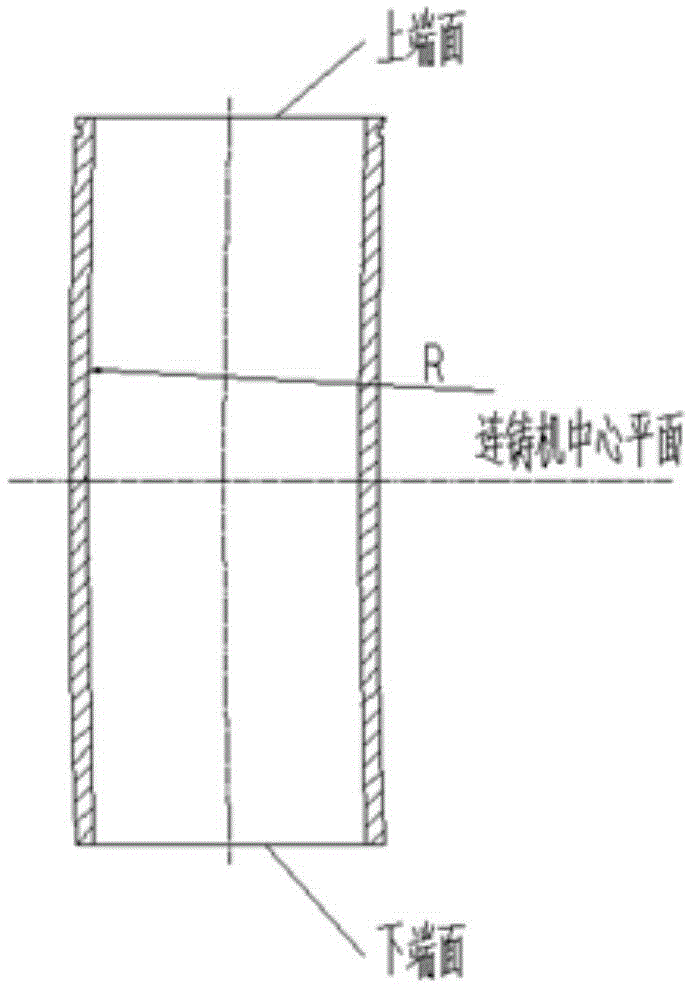

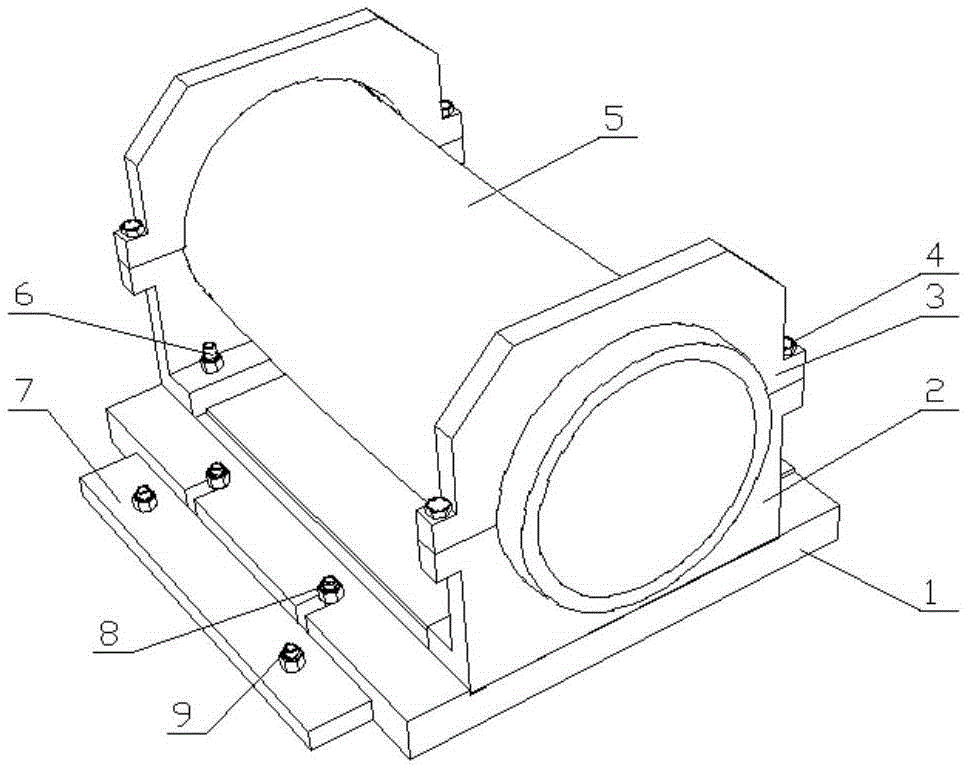

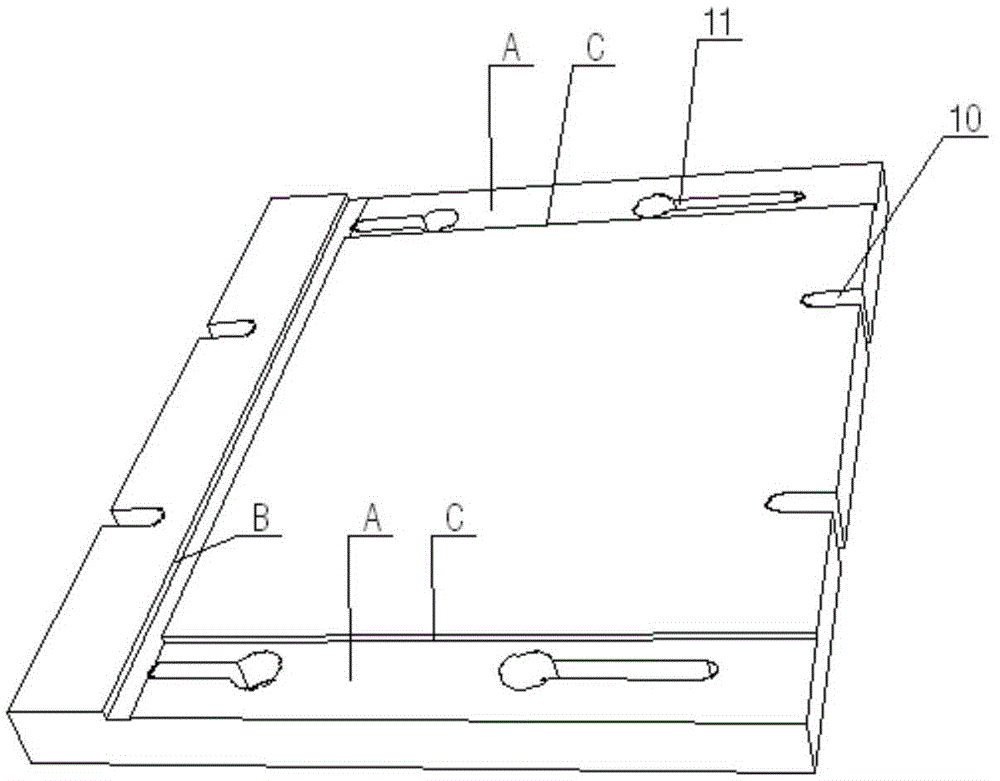

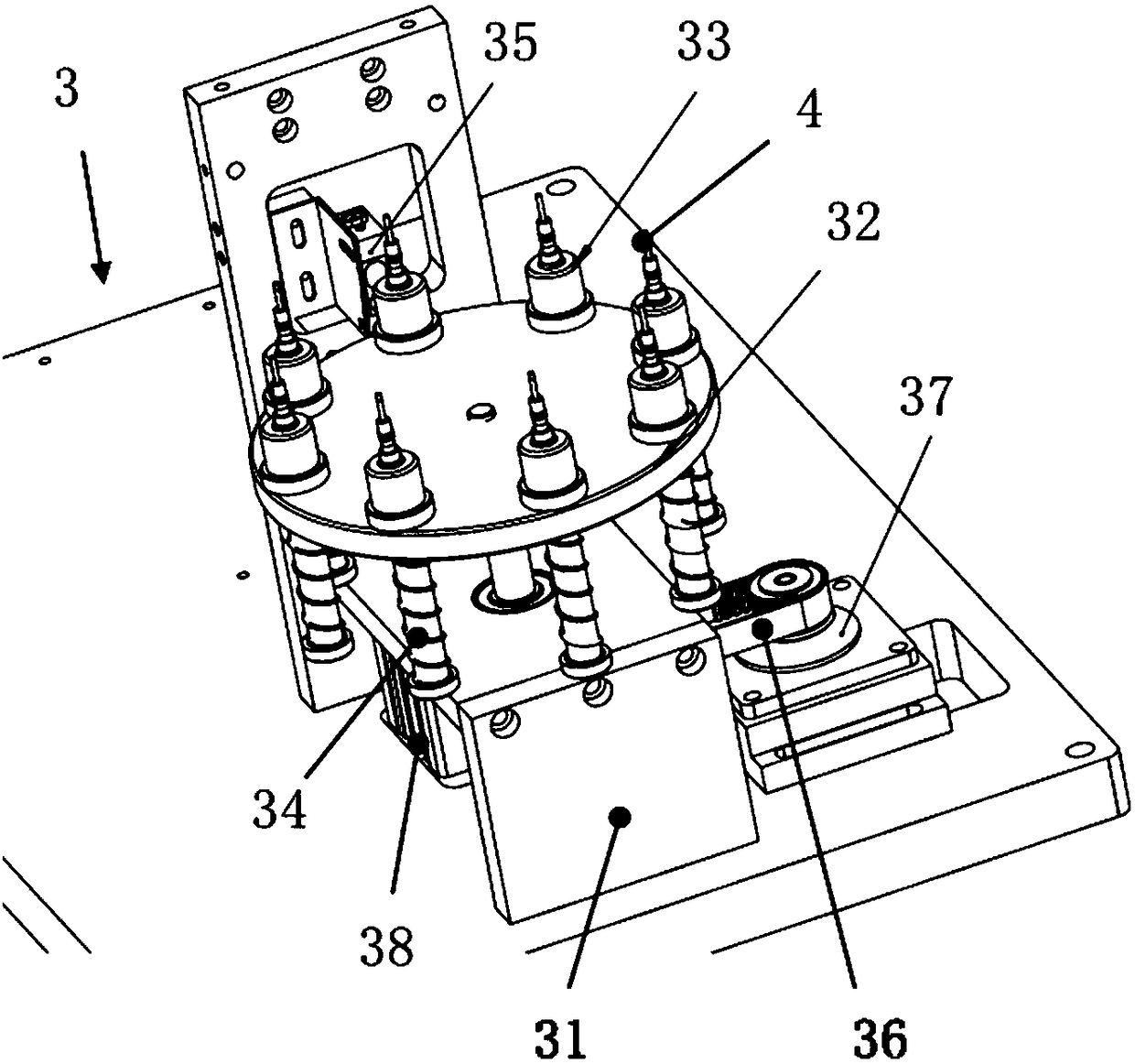

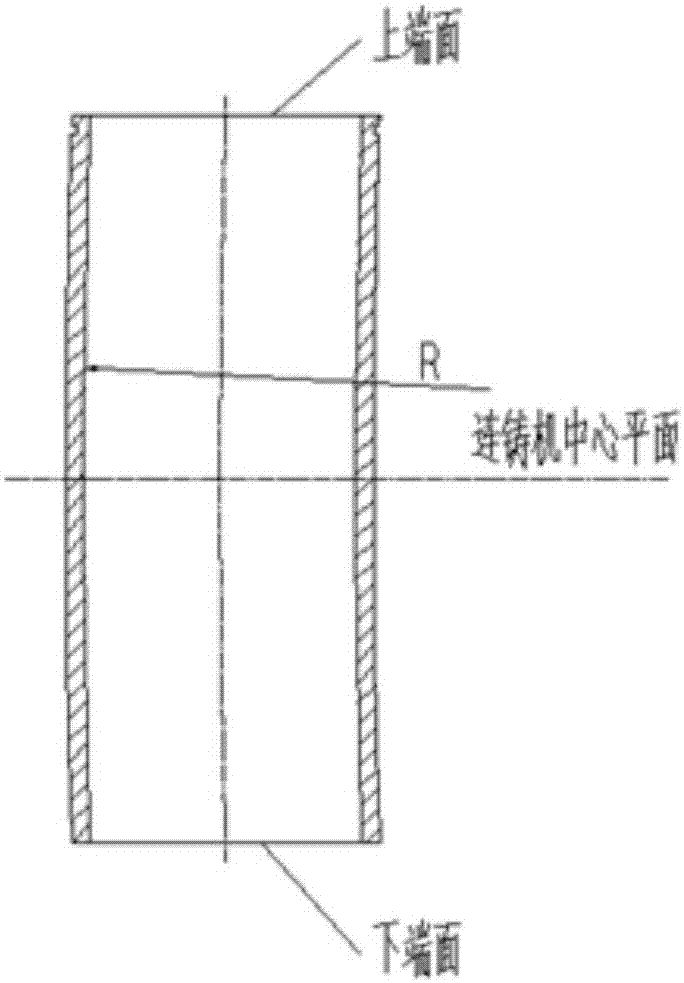

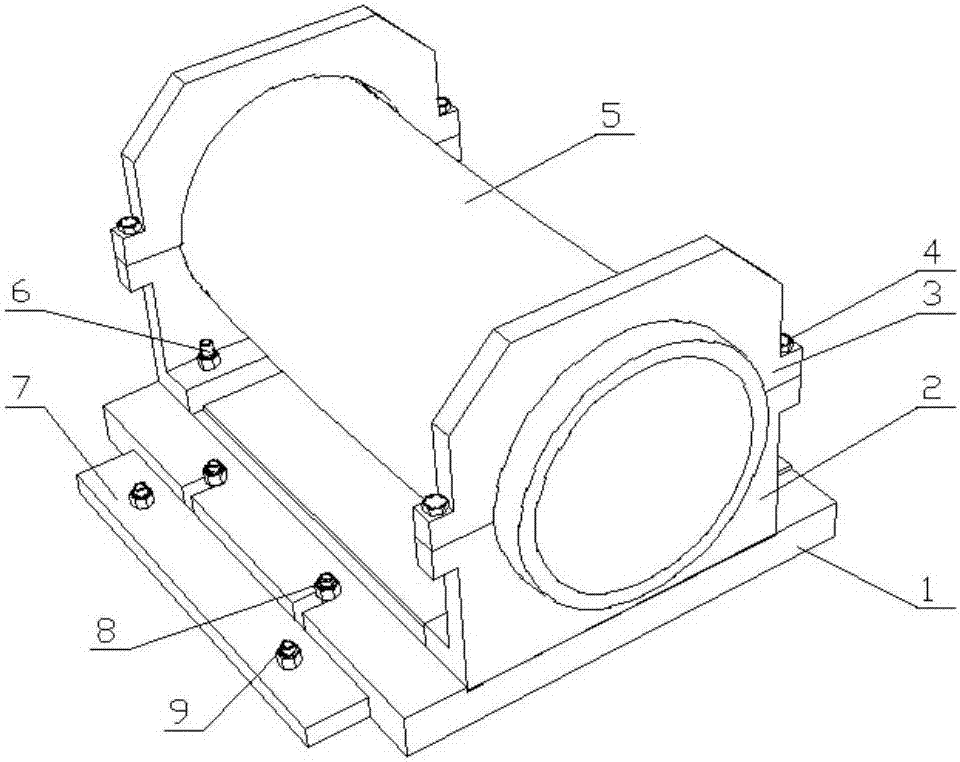

Special combined fixture for machining upper end face and lower end face of round mold crystallizer copper tube and use method of special combined fixture

ActiveCN104440219APrecise positioningAccurate installation and positioningPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention relates to a special combined fixture for machining the upper end face and the lower end face of a round mold crystallizer copper tube and a use method of the special combined fixture. The fixture comprises an installation bottom plate, a first set of upper and lower clamping plates, a second set of upper and lower clamping plates and a positioning plate. The installation bottom plate is used for arranging the fixture on a machine tool or a worktable. The first set of upper and lower clamping plates are vertically arranged at one end of the installation bottom plate, the second set of upper and lower clamping plates are vertically arranged at the other end of the installation bottom plate, the upper clamping plates correspond to the lower clamping plates from the upper portion, and preset shapes are formed between the upper clamping plates and the lower clamping plates so that the copper tube to be machined can be positioned and fixed. The positioning plate is arranged on the machine tool or the worktable and used for positioning the installation bottom plate. By means of the fixture, the standard of upper end face and lower end face machining of the copper tube difficult to precisely position is ingeniously transferred to the fixture, and precise installation and positioning of the copper tube are guaranteed through the specially designed structure of the fixture. Accordingly, errors caused by a lineation method or a simple backer are avoided, it is guaranteed that machined parts are precise and reliable, product quality is improved, and defective products are reduced.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

Health tea containing Chinese herbal medicines with functions of tonifying qi, replenishing blood, maintaining beauty and resisting fatigue and ageing

The invention discloses health tea containing Chinese herbal medicines with functions of tonifying qi, replenishing blood, maintaining beauty and resisting fatigue and ageing. The health tea comprises components in percentage by weight as follows: 5%-20% of sea buckthorn, 10%-50% of American ginseng, 5%-30% of polygonatum, 5%-20% of South dodder seeds, 5%-20% of kudzuvine roots, 10%-30% of Chinese yams, 10%-30% of astragalus membranaceus, 5%-30% of fructus lycii, 5%-20% of Chinese angelica, 5%-20% of raspberries and 5%-20% of rhodiola rosea. The health tea containing the Chinese herbal medicines with the functions of tonifying qi, replenishing blood, maintaining beauty and resisting fatigue and ageing can be scientifically prepared, has a remarkable effect, is accurate in dosage, moderate in price and safe and convenient to drink, doesn't have side effects if people take the health tea for a long time and strengthens the physique of people.

Owner:ZHEJIANG XINGYUAN BIOTECH CO LTD

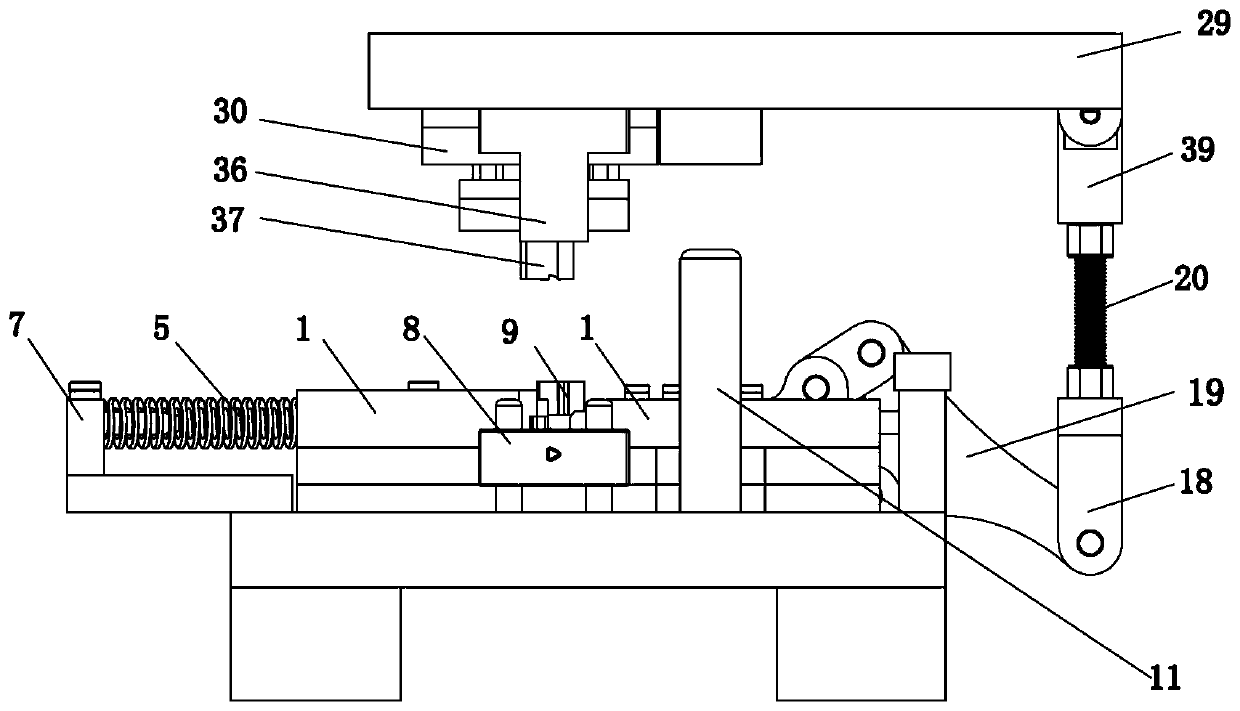

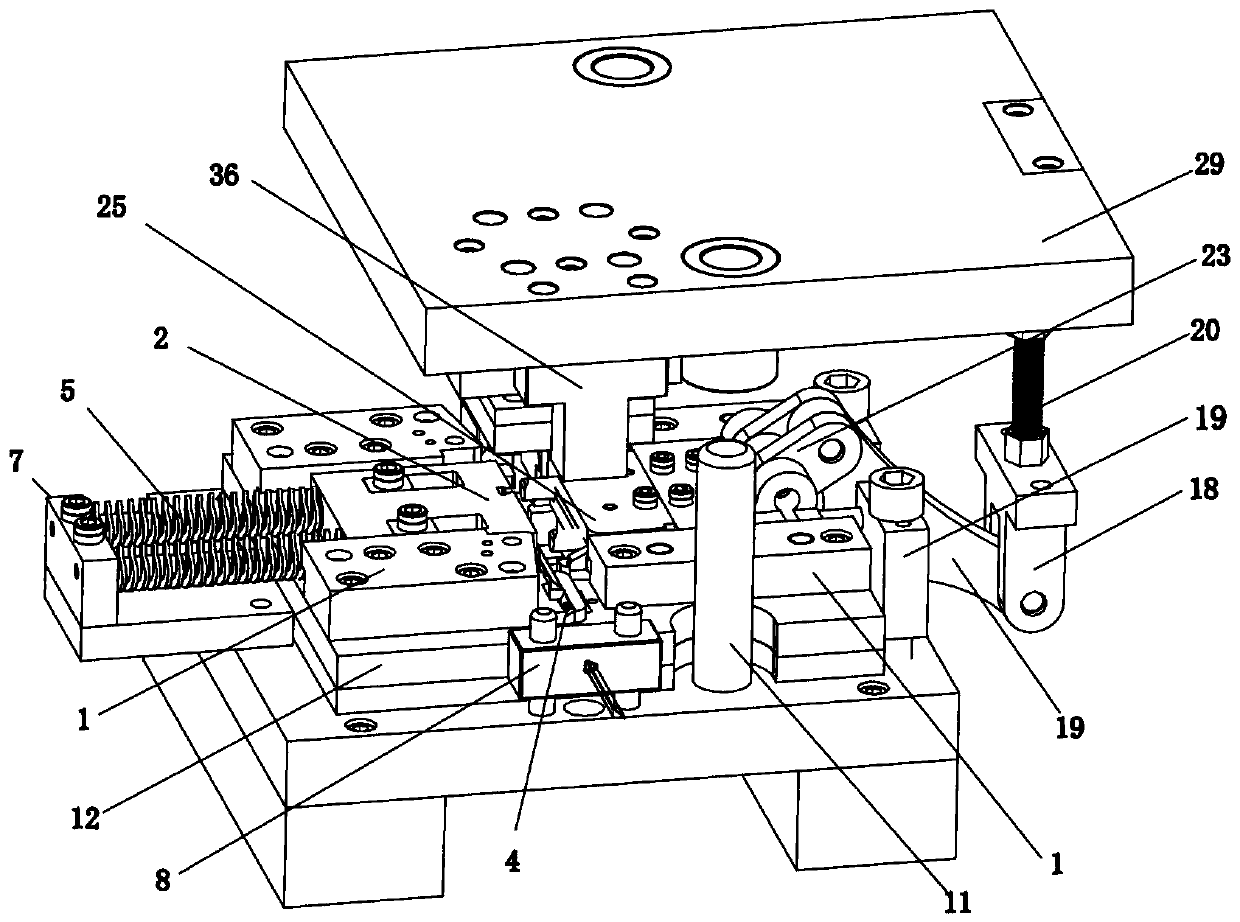

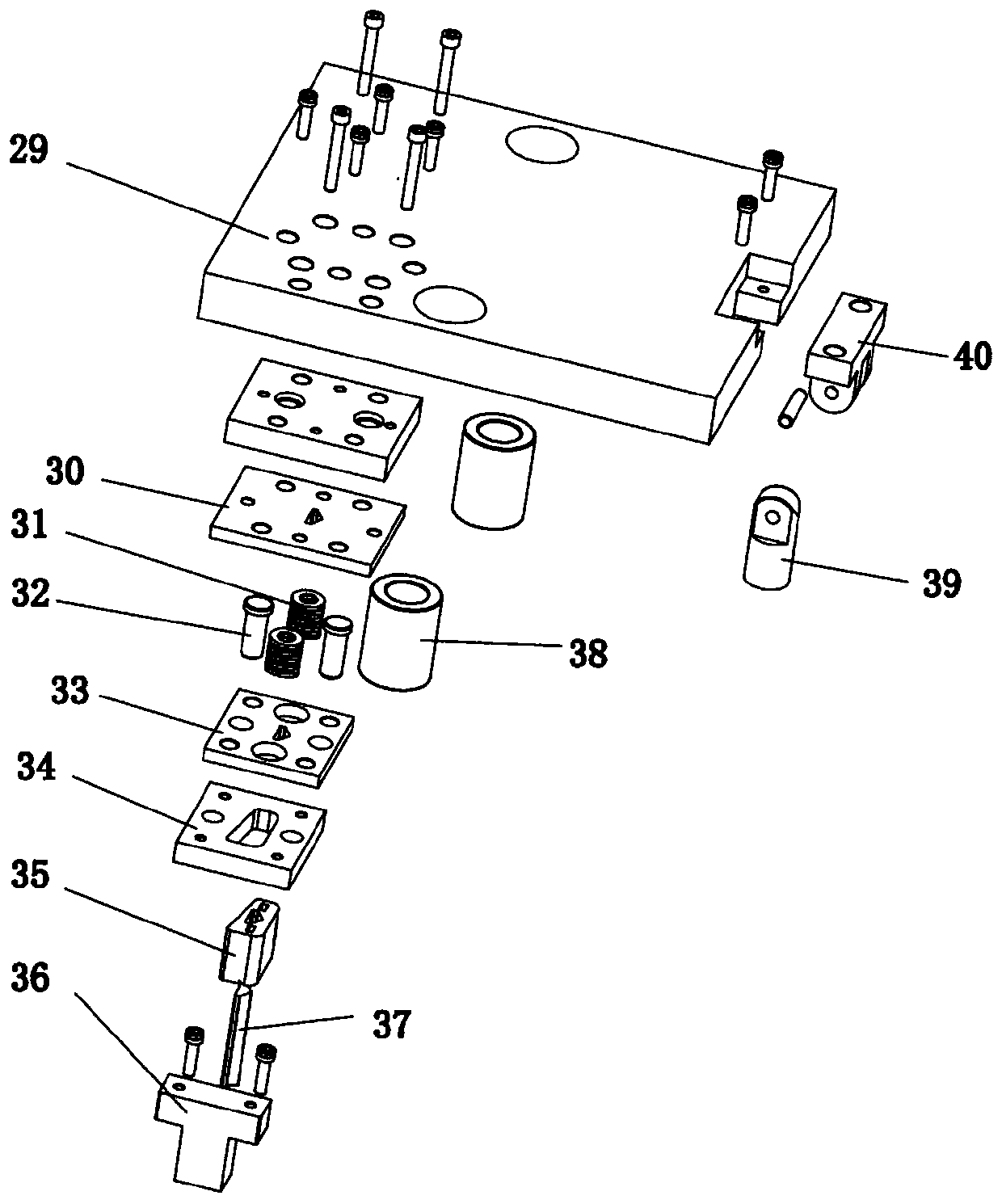

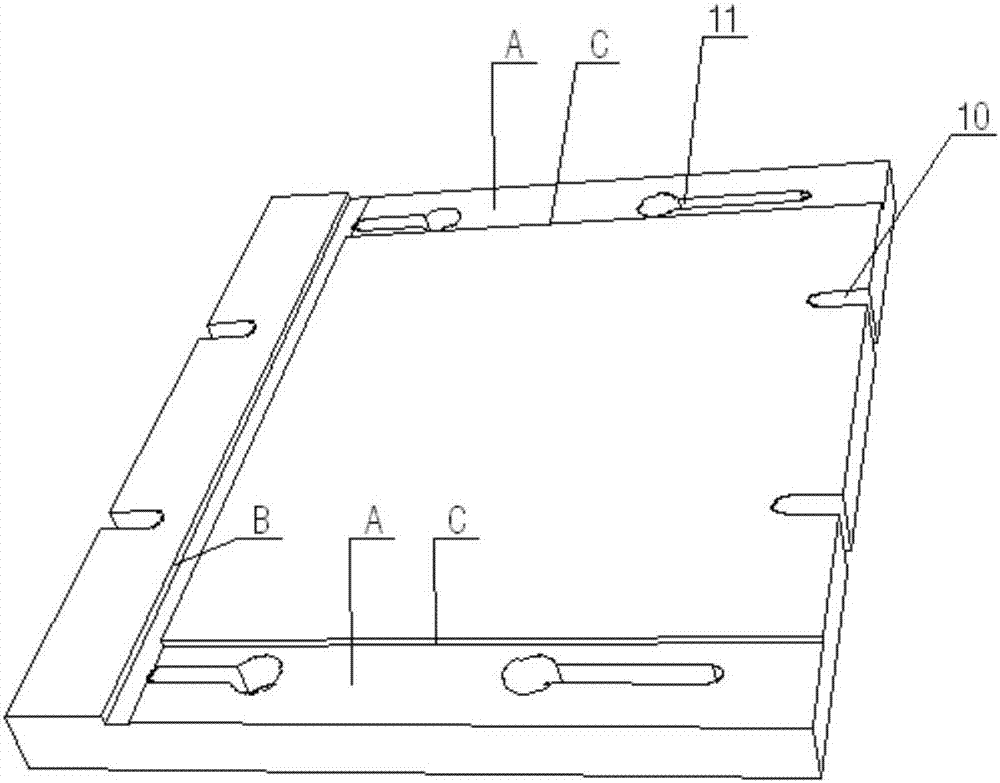

Continuous forming mold for manufacturing triangular cramp and continuously formed triangular cramp

ActiveCN111069466AImprove work efficiencyReliable product quality guaranteeWire articlesMachine buildingStructural engineering

The invention relates to a continuous forming mold for manufacturing a triangular cramp and a continuously formed triangular cramp, and belongs to the technical field of novel mechanical manufacturing. The continuous forming mold is composed of an upper mold assembly and a lower mold assembly; the upper mold assembly comprises an upper mold seat, an upper fixing plate, an upper stopping plate, anupper separating plate and a cutter sheath, and the upper fixing plate is fixedly provided with a cutter; the other end of the upper mold seat is hinged to a connecting rod sleeve; the lower mold assembly comprises a lower mold seat and a lower mold plate, a bent top block constituting a horizontal moving pair is fixedly mounted at one end of the lower mold plate, the other end of the lower mold plate is mounted in the middle of a lever in a hinged mode, the inner end of the lever is hinged to a bent sliding block with a bent punch, the bent sliding block and the lower mold plate constitute the horizontal moving pair, the side, spaced from the bent top block, of the bent punch is provided with a lower mold cutting opening, the lower mold cutting opening is provided with a V-shaped neutralgear matched with a cutting edge, and marking inserts are symmetrically distributed on the two sides of the V-shaped neutral gear; and the outer end of the lever is hinged to a lower connecting rod seat, and the lower connecting rod seat is fixedly connected with a connecting sleeve. The working efficiency of the continuous forming mold is greatly improved, and the product quality is reliably guaranteed.

Owner:NANJING TENGYA PRECISE TECH DEV CO LTD

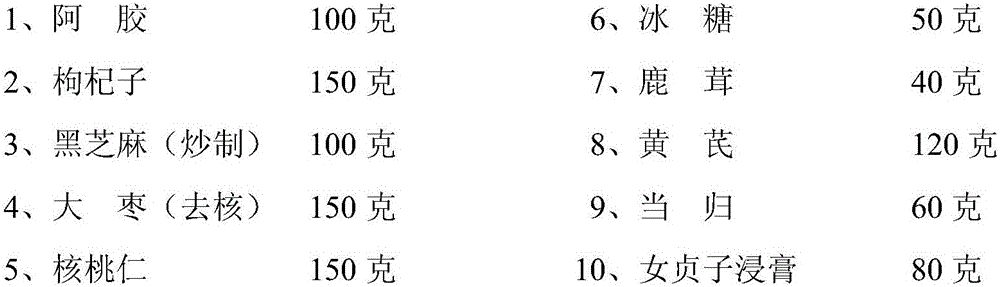

Nourishing paste with functions of producing blood, tonifying kidney, blacking hair and strengthening physique

PendingCN106666733ACombination scienceGood effectOrganic active ingredientsDispersion deliveryDiseaseSide effect

The invention provides nourishing paste with functions of producing blood, tonifying kidney, blacking hair and strengthening physique. The nourishing paste is prepared from the following raw materials in parts by weight: 5-15 parts of donkey-hide gelatin, 10-20 parts of fructus lycii, 5-15 parts of semen sesami nigrum, 10-20 parts of fructus jujubae, 10-20 parts of semen juglandis, 5-10 parts of rock candies, 3-8 parts of cornu cervi pantotrichum, 10-15 parts of radix astragali seu hedysari, 2-10 parts of Chinese angelica and 5-15 parts of glossy privet fruit extract. The nourishing paste is a health food with the functions of producing blood, tonifying kidney, blacking hair and strengthening physique, and is scientific in prescription compatibility, remarkable in effect, safe and convenient and free from toxic and side effects; the nourishing paste is beneficial to industrial and standardized production and popularization, and is applied to health maintenance, disease prevention and sub-health state conditioning.

Owner:郭志忠

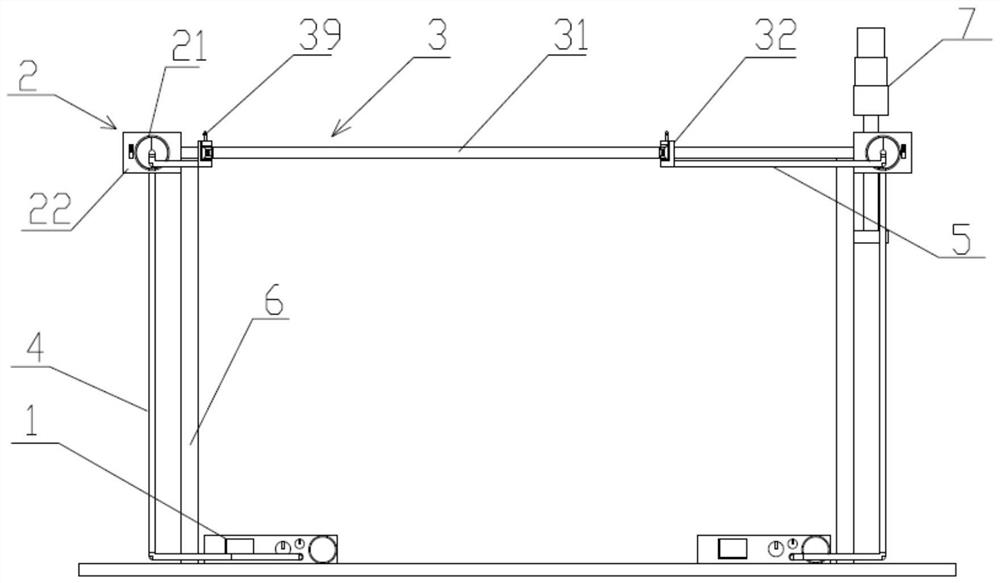

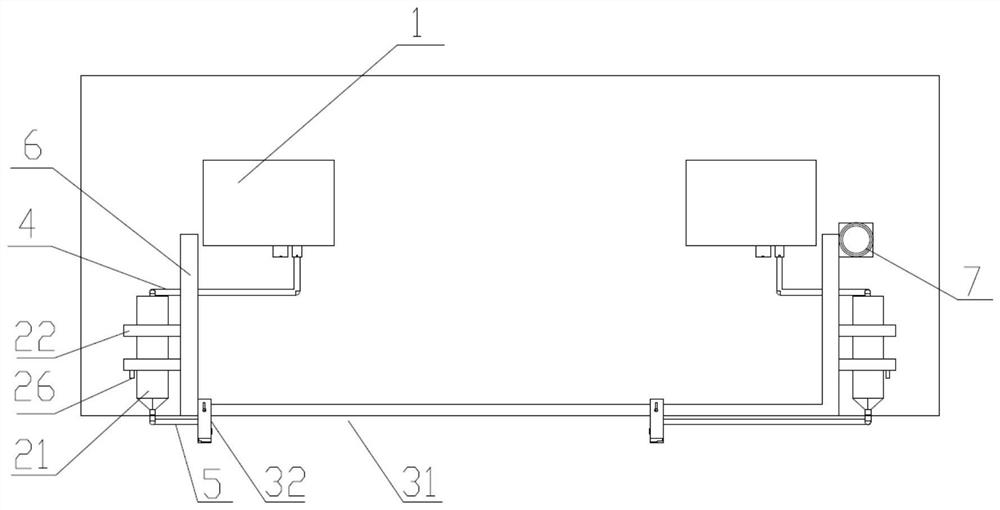

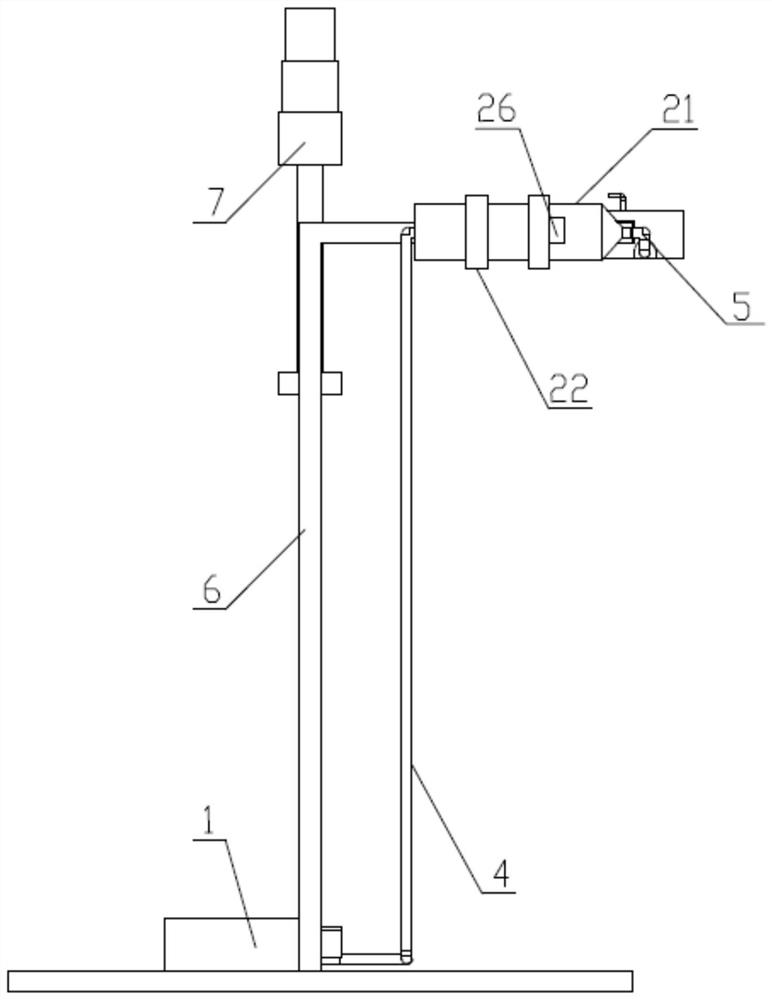

Main feeder jumper manufacturing tooling and working method

ActiveCN106207701BReduce skillsReduce labor intensityContact member assembly/disassemblyAntenna connectorsProduction lineElectrical conductor

The invention provides a manufacturing tooling device of a main feeder jumper and a working method of the manufacturing tooling device. The manufacturing tooling device comprises a clamping device, a putting and pressing device, at least one welding machine electrode opening and closing device and a welding automatic shift device, wherein the clamping device comprises a housing; a cable and a center conductor penetrate into the housing; the putting and pressing device supports the center conductor and presses the center conductor into the housing; the welding machine electrode opening and closing device is provided with an electrode bar clamp for clamping the center conductor and makes the center conductor emit heat; and the welding automatic shift device drives an induction welding head to weld an outer conductor of the cable and the housing. By the manufacturing tooling device of the main feeder jumper, the technical problems of low production efficiency, an overlong production line, high labor intensity, a large product quality control difficulty and the like are solved. The welding machine electrode opening and closing device 5 utilizes a third air cylinder to act, and is combined with a center conductor fixing device, so that the position at which the electrode rod clamp clamps the center conductor is fixed, the pressure is uniform and stable and the product quality is reliably ensured.

Owner:JIANGSU HENGXIN TECH CO LTD

An installation method for installing prefabricated bay windows on laminated wall panels

Owner:BAOYE GROUP CO LTD +1

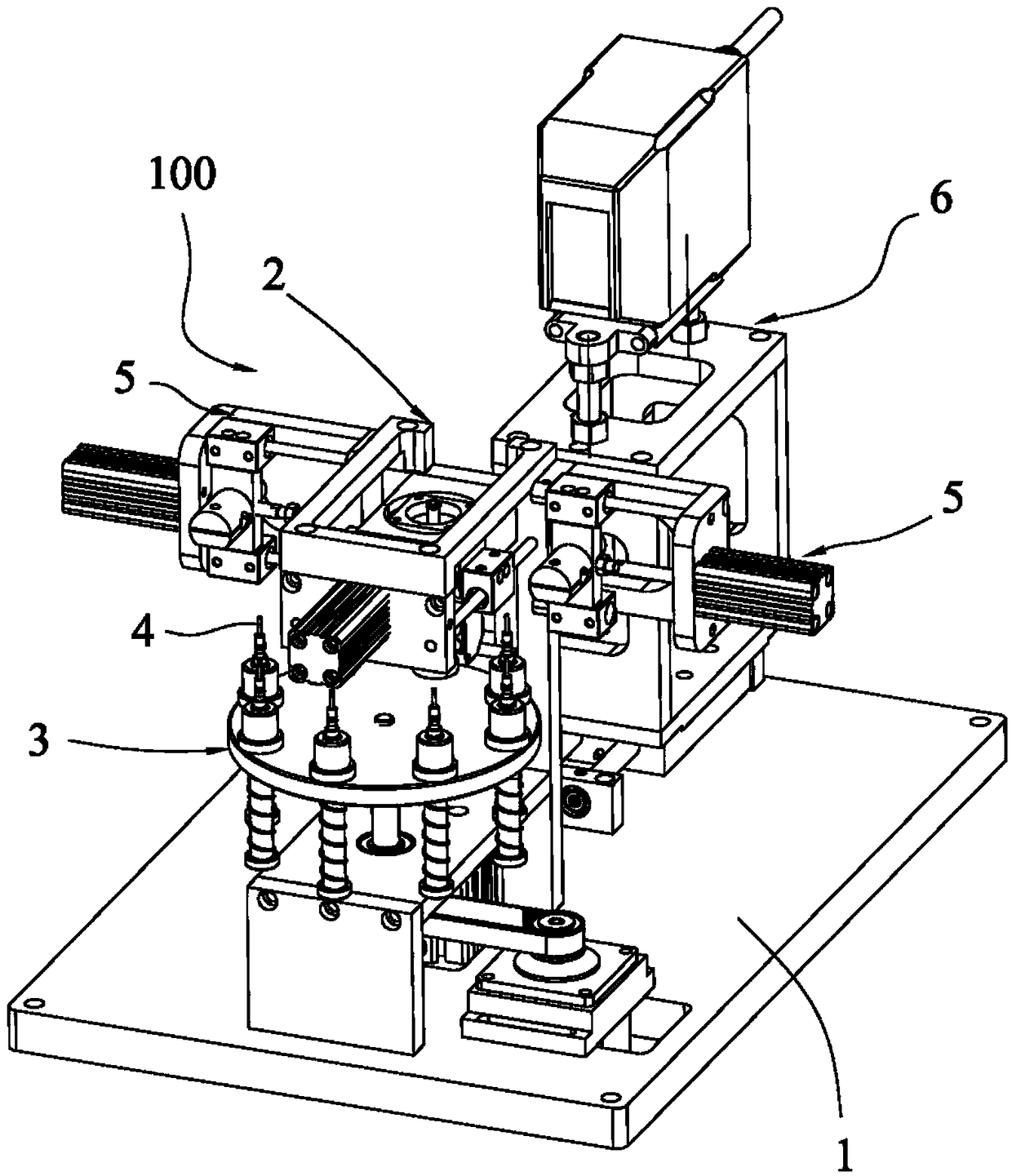

Oil coating system and air conditioner production line

PendingCN112791910AControl oil outputApply evenlyLiquid surface applicatorsCoatingsCoating systemProcess engineering

The invention provides an oil coating system and an air conditioner production line. The oil coating system comprises an oil control device, an oil storage device and an oil outlet device which are sequentially connected; the oil control device is used for controlling the oil storage device to guide out the silicon grease; the oil storage device is used for conveying the silicon grease to the oil outlet device; and the oil outlet device is used for outputting the silicon grease and coating an end shaft of an air deflector with the silicon grease. By means of the oil control device, the oil storage device and the oil outlet device, the oil outlet amount of the silicon grease can be controlled, the silicon grease can be evenly smeared on the end shaft of the air guide plate, the oil smearing amount on the air guide plate is kept consistent, the production efficiency is improved, the product quality is reliably guaranteed, and the labor intensity of operators is greatly reduced.

Owner:GREE ELECTRIC APPLIANCES INC

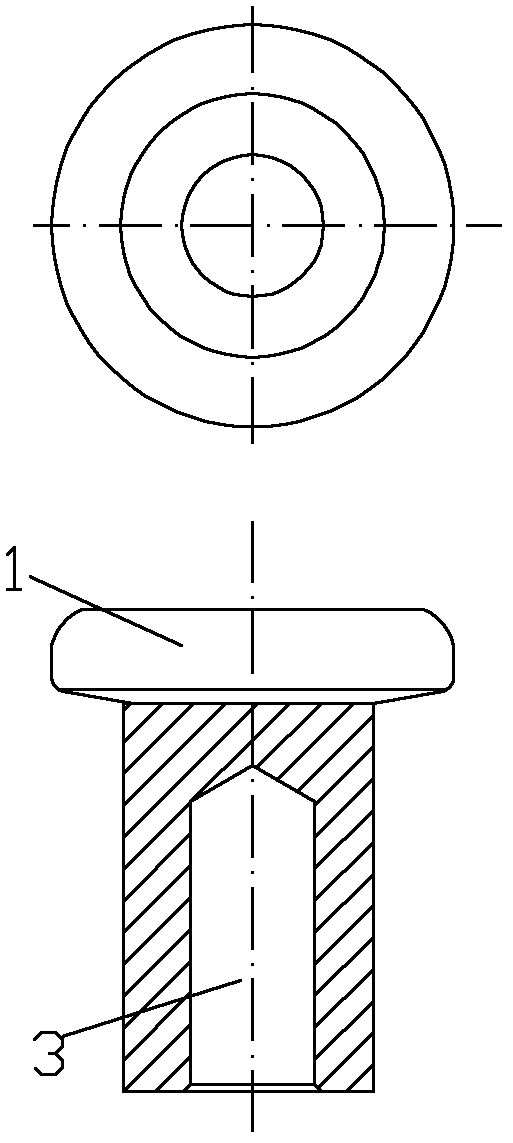

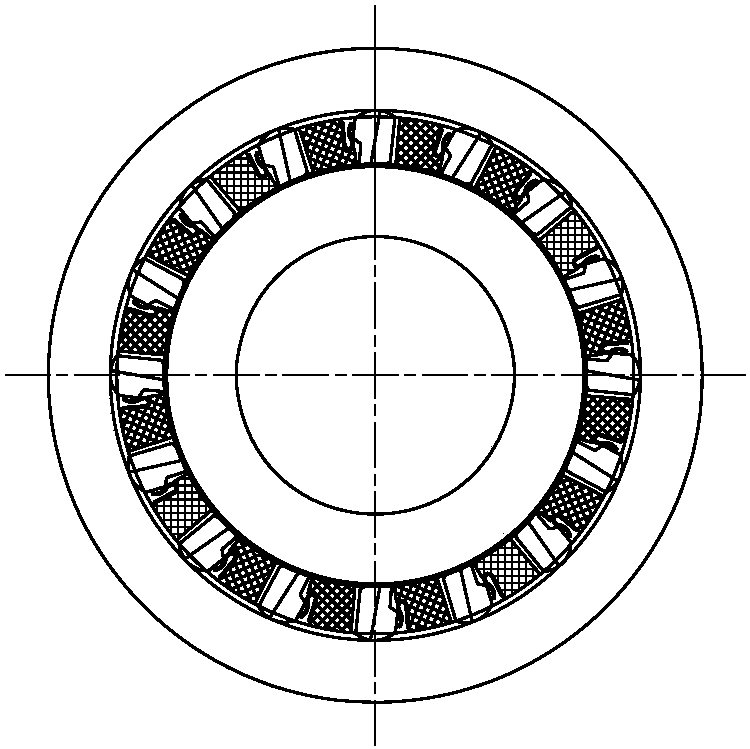

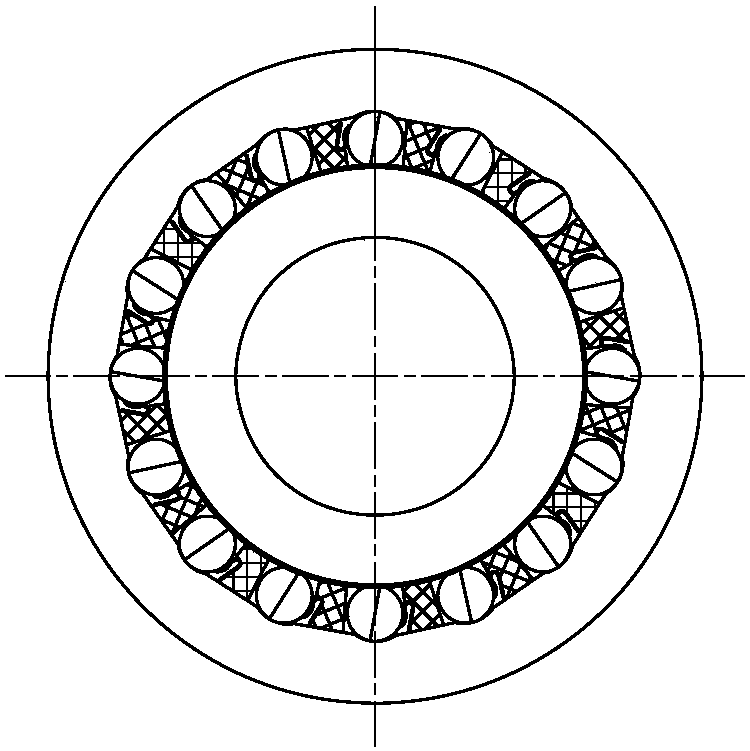

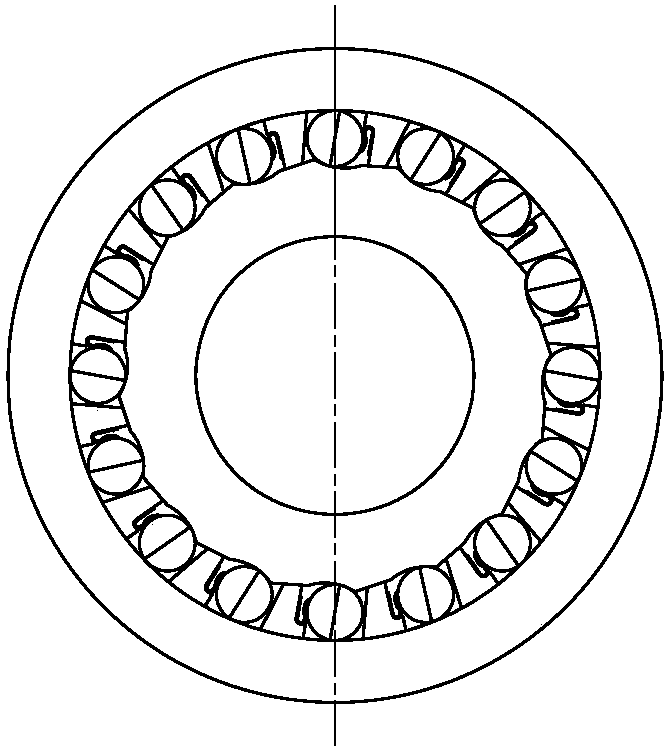

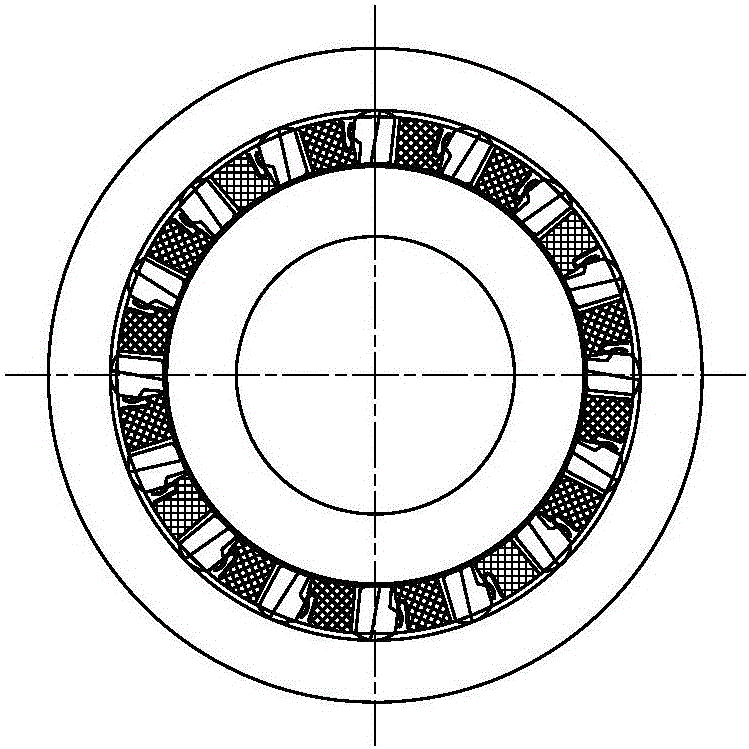

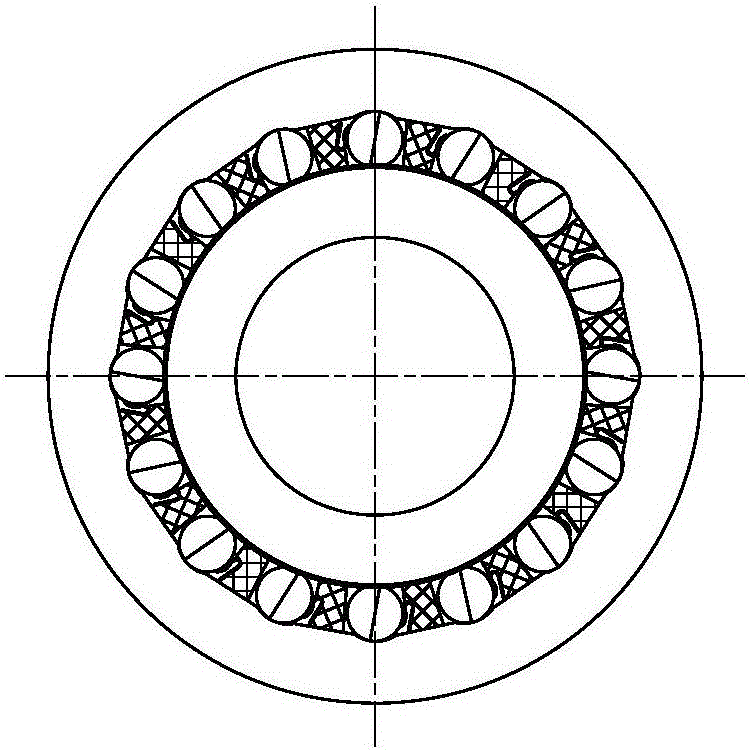

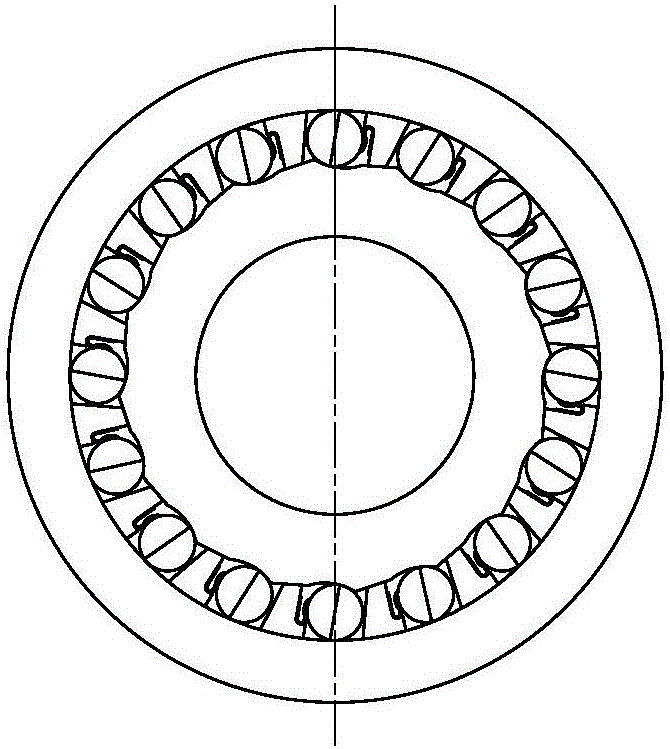

One-way clutch bearing

ActiveCN106015389BCompact structureEasy to processBearing assemblyBall bearingsEngineeringMachining process

This invention relates to one-way clutch bearings. The outer ring and the inner ring are divided into a rolling element installation section and a needle roller installation section in the axial direction. Raceways are arranged on the inner wall of the outer ring and the outer wall of the inner ring of the rolling element installation section, and several rolling elements are arranged on the outer ring and the inner ring. In the upper raceway, the rolling element cage evenly separates several rolling elements; several groups of needle roller groups are arranged between the inner wall of the outer ring and the outer wall of the inner ring of the needle roller installation section, and the needle roller cage separates several groups of needle rollers. The groups are evenly separated; each needle roller group includes the first needle roller and the second needle roller, the first needle roller and the second needle roller are installed in the holding groove on the needle roller cage, the first needle roller and the second needle roller There is a pressure angle between the center line of the two needle rollers and the contact pressure direction of the inner ring; the first needle roller is located at the radially inner end of the retaining groove, the first needle roller is in contact with the outer wall of the inner ring, and the second needle roller is located radially outward of the retaining groove end, the second needle roller is in contact with the inner wall of the outer ring. The invention has the advantages of simple and compact structure, good processability, high precision and guaranteed product quality.

Owner:WUXI NO 2 BEARING

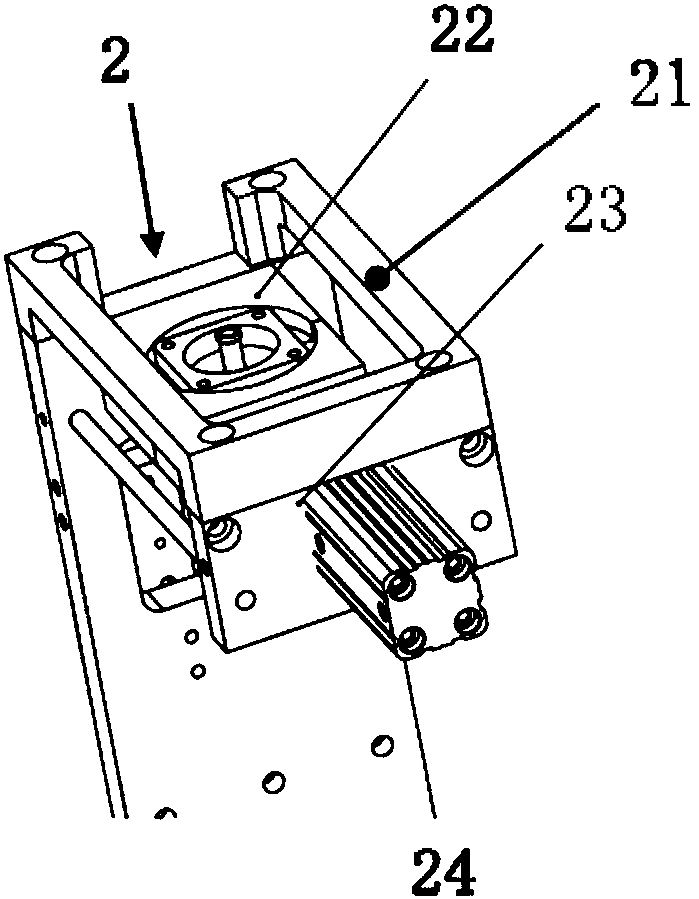

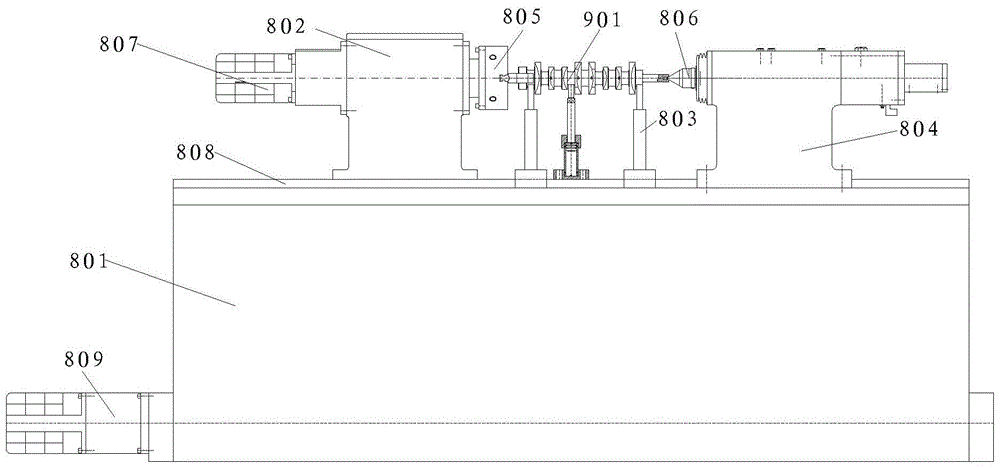

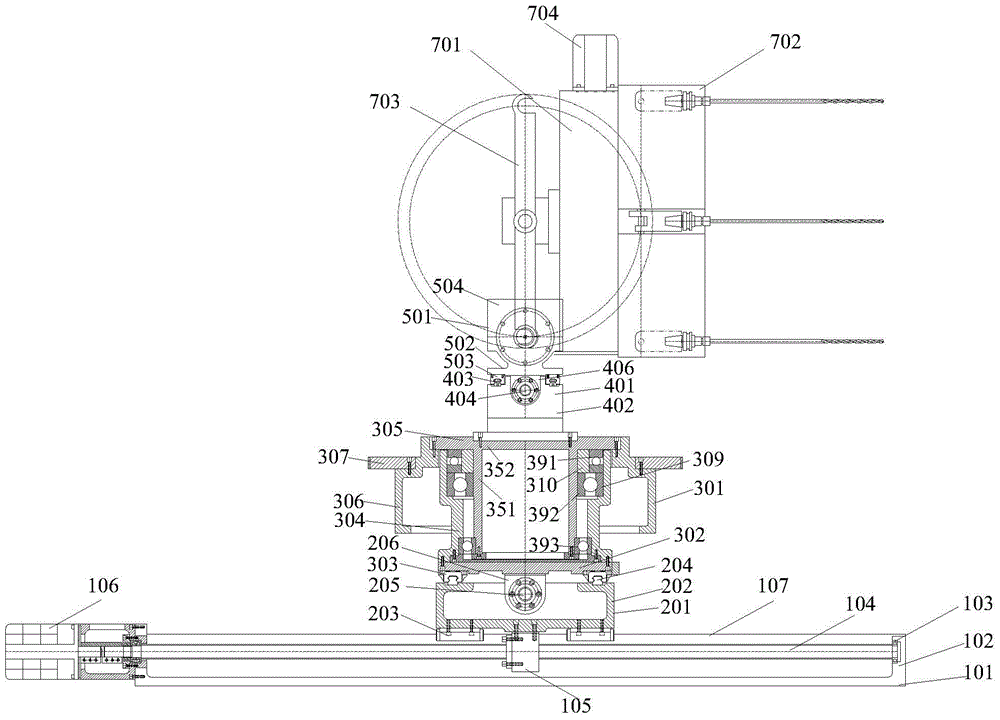

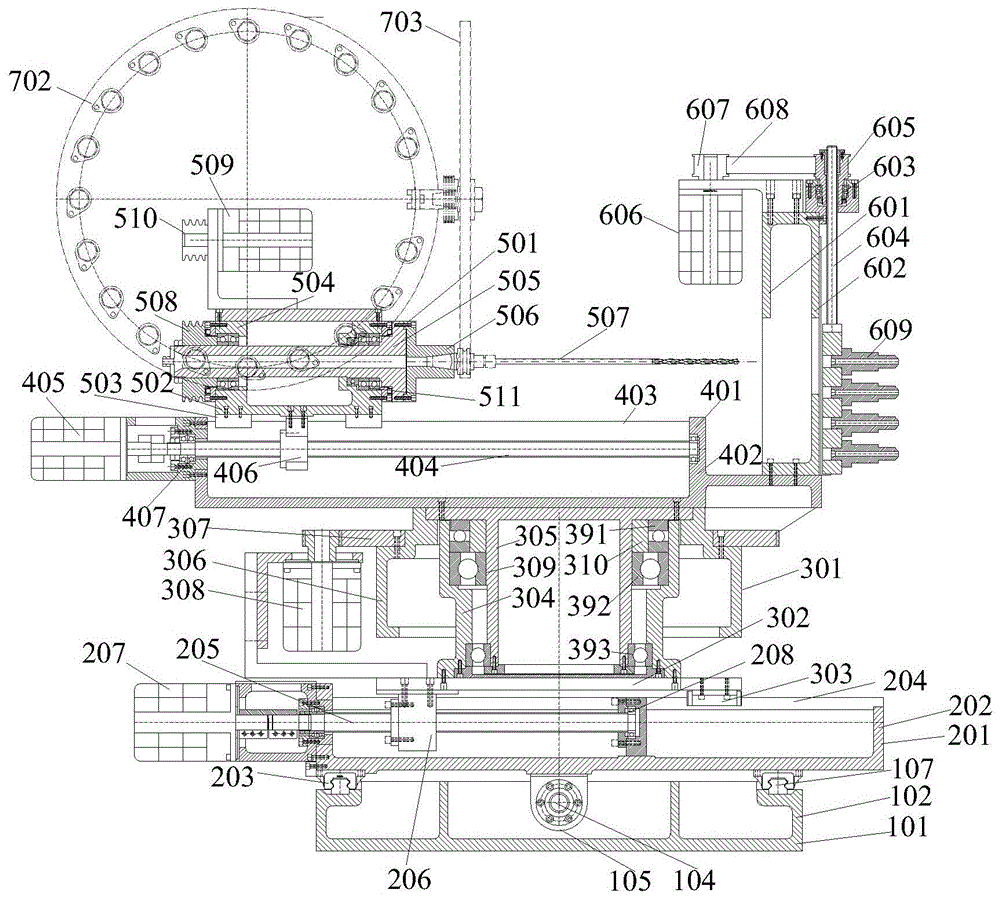

CNC large engine crankshaft angle oil hole drilling rig mechanism

ActiveCN104275508BGuaranteed Limit AdjustmentGuaranteed automationLarge fixed membersBoring/drilling componentsMechanical equipmentEngineering

The invention relates to a numerically-controlled drill mechanism for drilling angled oil holes in large-sized engine crankshafts and belongs to the technical field of mechanical equipment. The numerically-controlled drill mechanism comprises a main frame and a bit mechanism; the bit mechanism comprises an axial movement mechanism; a transverse movement mechanism perpendicular to the axial movement mechanism is slidably connected to the upper portion of the axial movement mechanism. A turntable mechanism is slidably connected to the upper portion of the transverse movement mechanism and comprises a turntable mounting plate with the bottom slidably connected to the transverse movement mechanism. The upper portion of the turntable mounting plate is fixedly connected with the bottom of a rotating shaft sleeve. An inner ring of the rotating shaft sleeve is movably connected with a mounting sleeve through a connection structure. An outer ring of the rotating shaft sleeve sleeves the turntable. The upper portion of the turntable is fixedly connected with the upper portion of the mounting sleeve. A rotating gear is fixed to the outside of the turntable and connected with a first motor. The turntable allows the angle of a bit to be automatically adjusted as required.

Owner:湖北伟翔数控机床股份有限公司

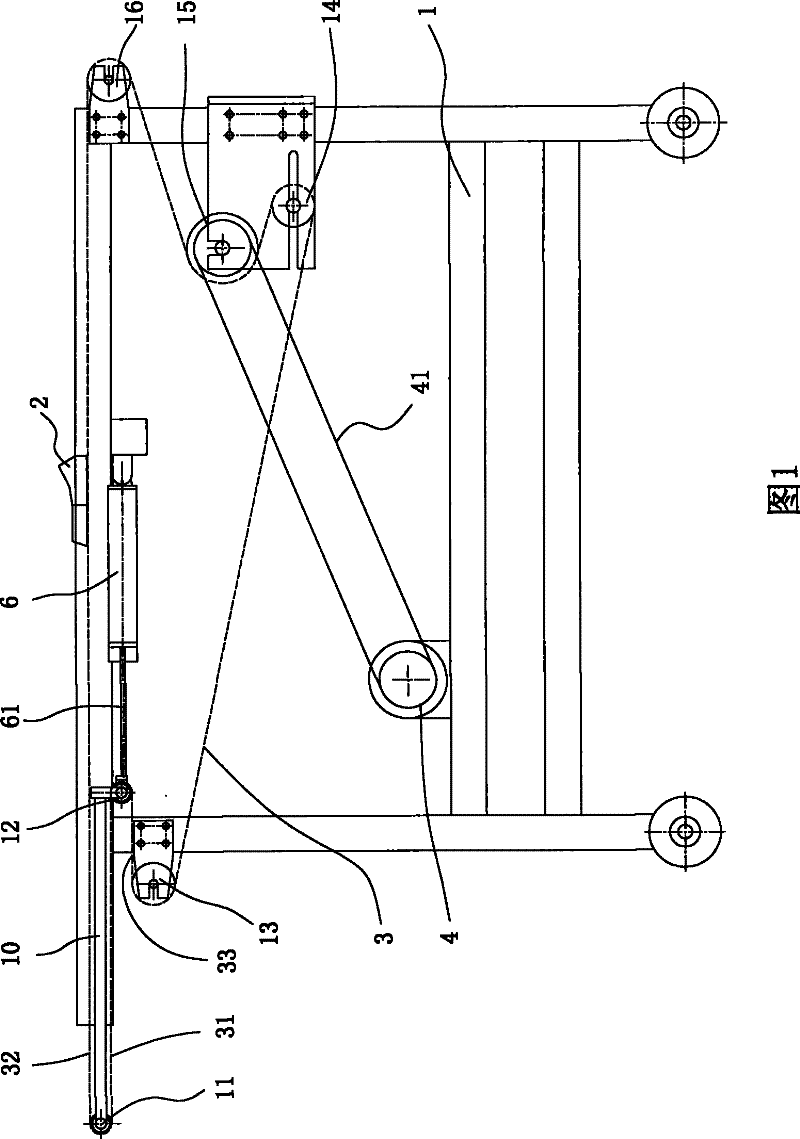

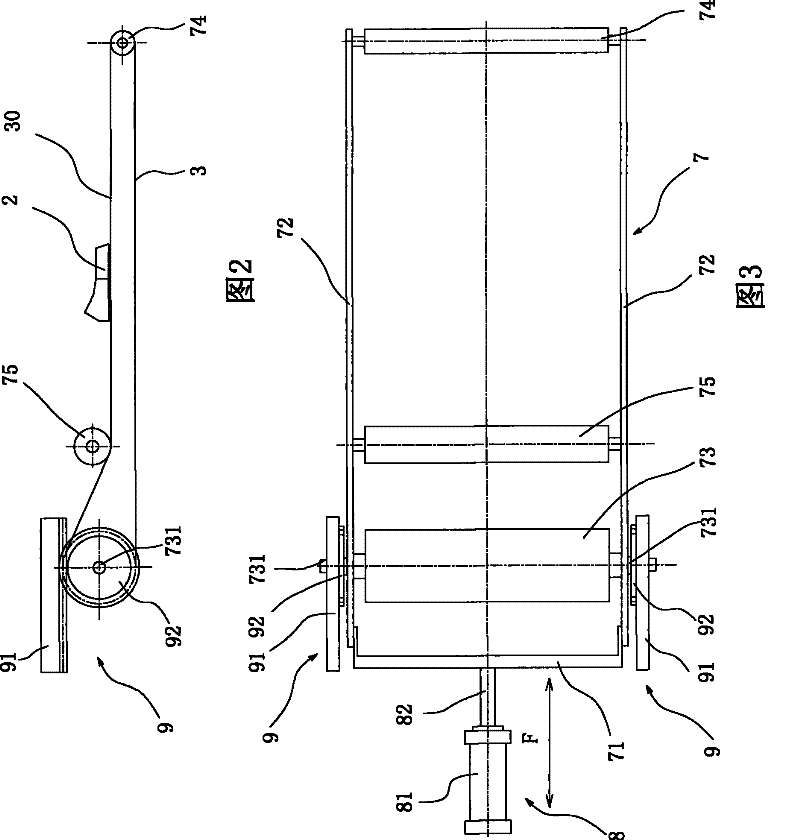

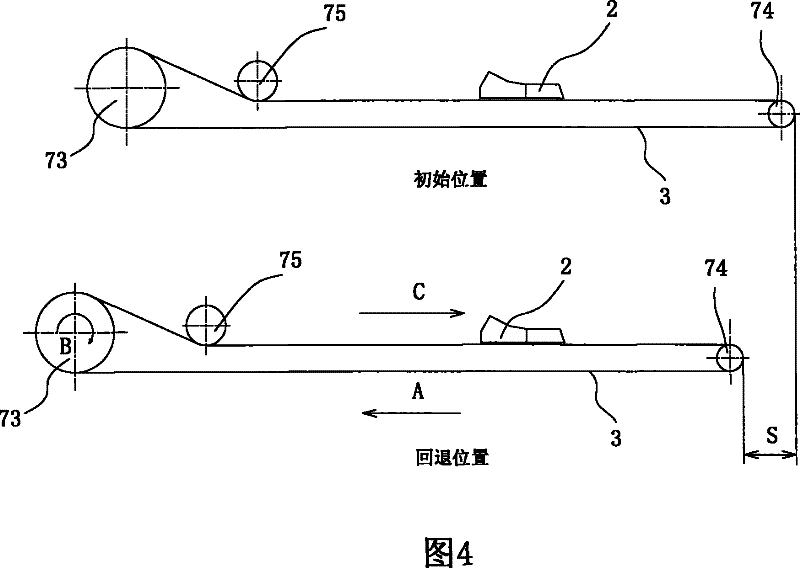

Conveyer belt apparatus

The invention provides belt equipment, which comprises a movable stand, a drive mechanism connected to the movable stand and a compensation drive mechanism. A dynamic roller and a static roller which keeps a certain distance from the dynamic roller are pivotally arranged on the movable stand along the direction vertical to the moving direction of the movable stand, a conveyor belt is arranged around the peripheries of the two rollers, and the compensation drive mechanism is linked with the dynamic roller and provides speed increment for the conveyor belt along the direction opposite to the moving direction of the movable stand driven by the drive mechanism. The belt equipment has very simple structure, low maintenance cost and greatly reduced energy loss of power transmission, and can lead the diameter of the static roller at the front end of the conveyor belt to be very small, reduce the distance of the product cut off by a cutter to a tray and improve the problem of impact deformation of the product when falling on the tray from the conveyor belt.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

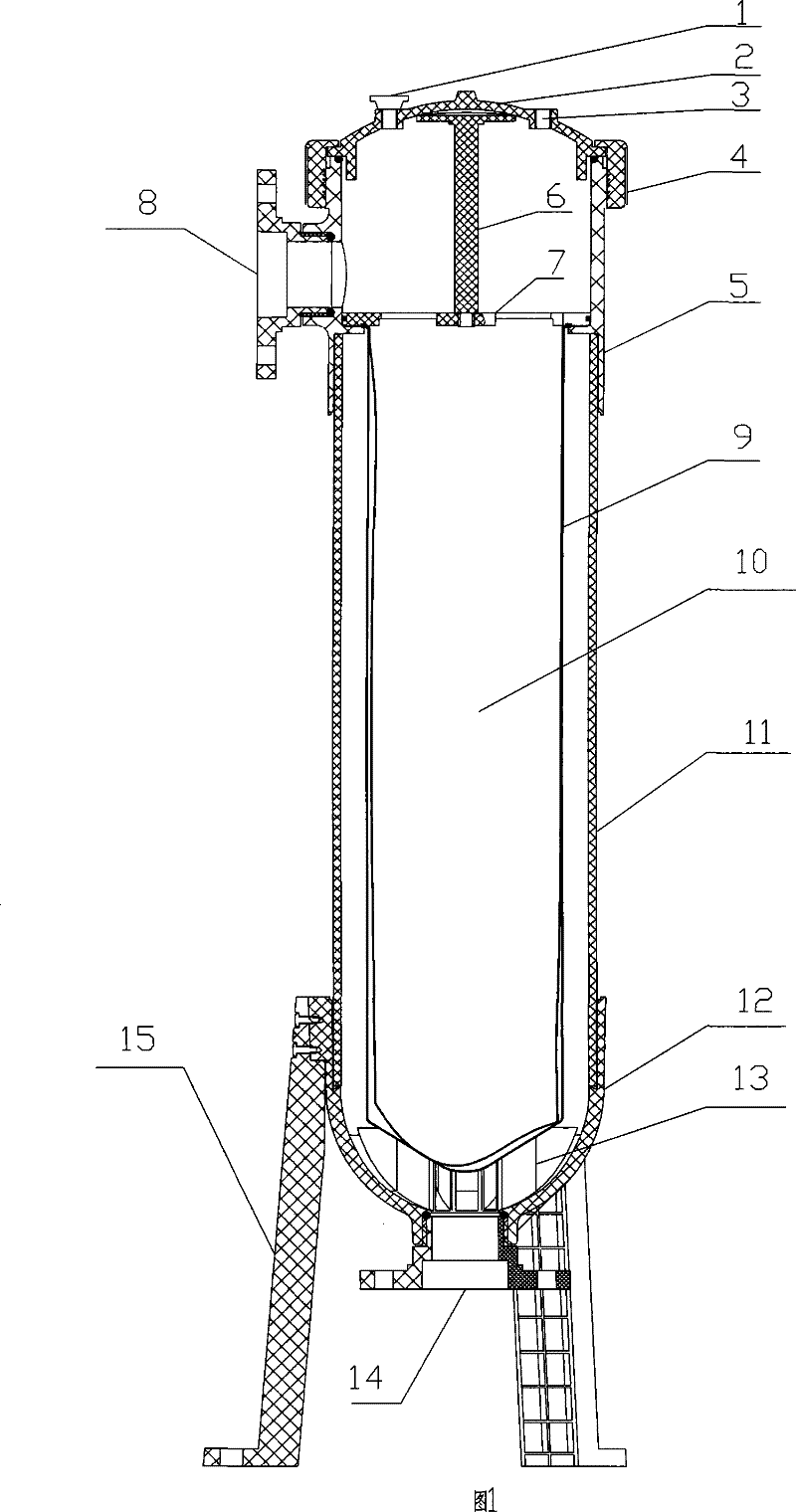

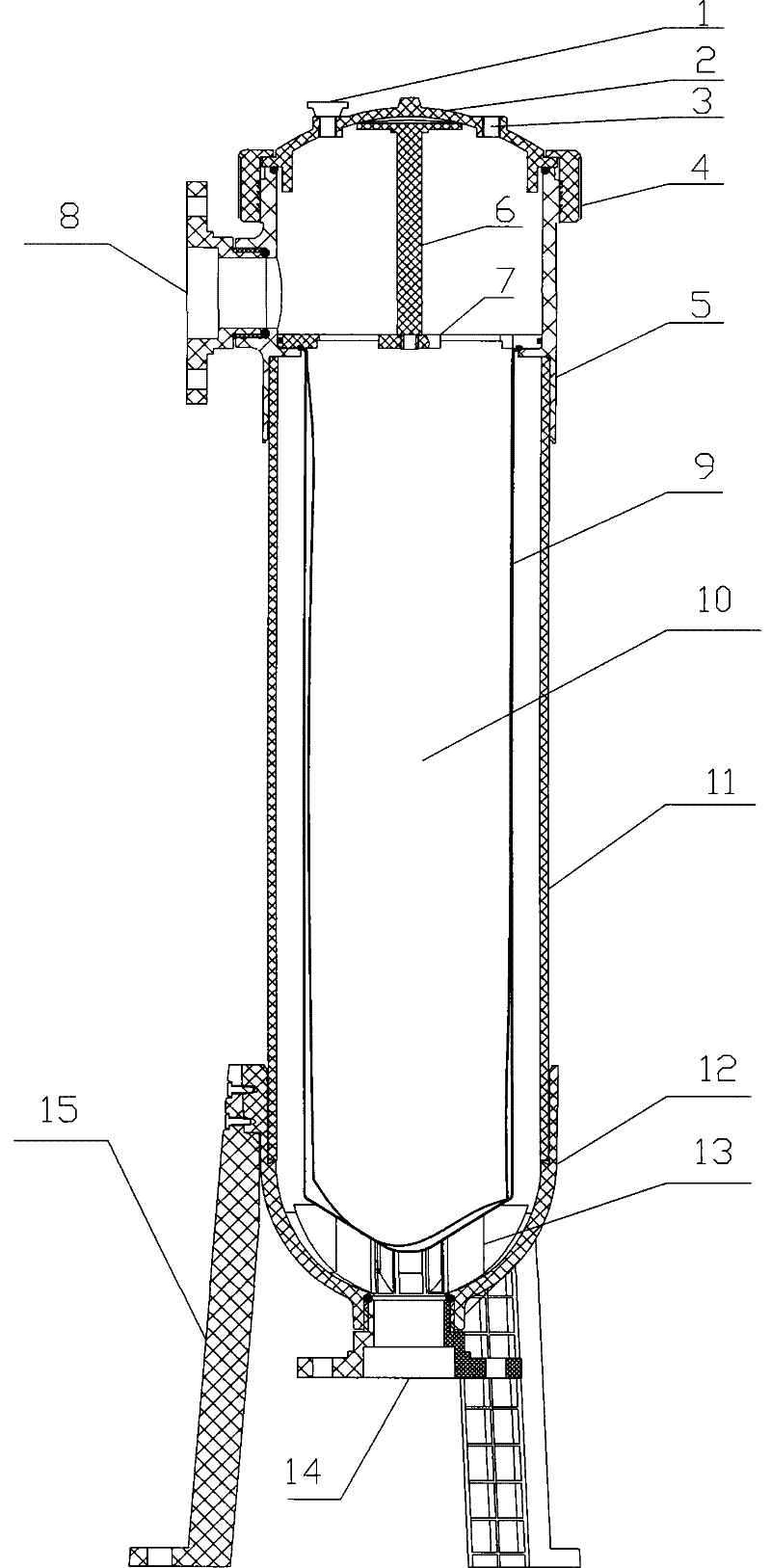

Bag filter

ActiveCN101337140BEasy to replaceReduce use costStationary filtering element filtersFlangeBag filter

The present invention discloses a bag type filter including a filtering basket, a filtering bag, a cylinder and several supporting legs. Said filtering bag is provided on the inner wall of the filtering basket which is fixed in the cylinder, the supporting legs are arranged on the bottom of the cylinder. The filter also includes an upper liquid feeding part, a lower press plate and a top cover. The upper liquid feeding part is provided with a locating fin on the inner wall and a liquid feeding por in the side surface, the upper liquid feeding part is fixed on the mouth of the cylinder via thelocating fin, and a liquid feeding flange is arranged at the liquid feeding port, the tope cover is sealed over the upper liquid feeding part, a lower liquid discharging part is arranged on the bottom of the cylinder and is provided with a liquid discharging port, and a liquid discharging flange is arranged at the liquid discharging port. The product of the invention has a reasonable structure and easily replaceable parts, and can avoid the inner leakage such that the quality of product is guaranteed. The filter is made entirely of plastics, which reduces the yield cost and use cost. It adopts UPVC material which makes the product work normally under the condition of acid-alkali and humidification.

Owner:湖州恒鑫过滤科技有限公司

Health-care tea containing antifatigue anti senility Chinese herbal medicine

InactiveCN100370914CFormulation ScienceGood effectTea substituesDrug compositionsTraditional medicineLycium

The present invention provides a health-care tea containing Chinese medicinal materials with the functions of resisting fatigue and resisting senility. Its composition includes 10 Chinese medicinal materials of sea-buckthorn 5-20%, American ginseng 10-50%, polygonatum root 5-30%, cuscuta seed 5-20%, pueraria root 5-20%, astragalus root 10-30% and others.

Owner:郭志忠

Method for cold forming of pipe fittings

The invention discloses a method for cold forming of pipe fittings. In manufacturing of metal pipe fittings, PCH alkane filler serves as a pressure transmitting medium, and axial compensation of metal pipe blanks is performed on a multidirectional hydraulic forming machine by the aid of a die. The whole forming process is completed under a cold condition. By the method for cold forming of the pipe fittings, a new approach is provided for cutting-free or less-cutting deep machining of metal materials.

Owner:重庆麦卡瑞机械制造有限公司

Tea capable of digesting and smoothing intestine and preparation method thereof

The invention discloses a tea capable of digesting and smoothing intestine. The tea is prepared from the effective ingredients of the following raw materials by mass percent: 5%-30% of India Buead, 5%-30% of semen raphani, 10%-25% of semen cassiae, 10%-25% of dandelion, 10%-25% of hawthorn, and 10%-20% of folium mori, and the total mass percent of the above components is 100%. The invention further discloses a preparation method of the tea capable of digesting and smoothing intestine. The method comprises the following steps: cleaning weighed raw materials, and then mixing; crushing accordingto a general method, shaping, sterilizing and drying. The tea capable of digesting and smoothing intestine has the effects of clearing heat and detoxicating, improving appetite and promoting digestion, smoothing intestine and relieving constipation and promoting metabolism, has obvious effects of treating indigestion and constipation, and cannot produce toxic side effect on a human after drinkingfor a long time.

Owner:牛兴民

Roller coating machine

ActiveCN102974498BSolve Adhesion ProblemsSolve for uniformityPretreated surfacesCoatingsMachineIndustrial engineering

The invention relates to a roller coating machine. Workpieces needing to be coated are pushed into a material turnover frame of a material turnover mechanism; the material turnover mechanism rotates the material turnover frame; the workpieces are turned and are poured into a material blocking hopper; the workpieces are conveyed to a material storage hopper of a discharge mechanism by a discharge conveying machine; the workpieces are lifted by the discharge mechanism, then are arranged in order and roll into a vibration transmission rack according to a certain rule; the workpieces are conveyed to a synchronous material-pushing mechanism; the workpieces arranged tidily are pushed to a V-shaped groove of a synchronous material-loading mechanism by the synchronous material-pushing mechanism; the workpieces are subjected to position adjustment by the synchronous material-loading mechanism and then are pushed to a material hanging mechanism on a workpiece transmission rack; the material hanging mechanism drives the workpieces and feeds them into an automatic glue-rolling device; a glue liquid is uniformly roll-coated on the surfaces of the workpieces by the automatic glue-rolling device; the workpieces coated with the glue liquid are fed to an unloading mechanism by the workpiece transmission rack; and the workpieces coated with the glue liquid are fed to a material receiving hopper by the unloading mechanism, then are fed into a workpiece delivery wagon and then are output. The roller coating machine adopts a roll-coating technology to realize workpiece surface treatment, is efficient, saves energy, is environmentally friendly and is suitable for large-scale glue-rolling of tubular workpieces.

Owner:WUXI HUANENG SURFACE TREATMENT

Special combined fixture for processing the upper and lower end faces of the copper tube of the round billet crystallizer and its application method

ActiveCN104440219BPrecise positioningAccurate installation and positioningPositioning apparatusMetal-working holdersMachine toolCopper tubing

The invention relates to a special combined fixture for machining the upper end face and the lower end face of a round mold crystallizer copper tube and a use method of the special combined fixture. The fixture comprises an installation bottom plate, a first set of upper and lower clamping plates, a second set of upper and lower clamping plates and a positioning plate. The installation bottom plate is used for arranging the fixture on a machine tool or a worktable. The first set of upper and lower clamping plates are vertically arranged at one end of the installation bottom plate, the second set of upper and lower clamping plates are vertically arranged at the other end of the installation bottom plate, the upper clamping plates correspond to the lower clamping plates from the upper portion, and preset shapes are formed between the upper clamping plates and the lower clamping plates so that the copper tube to be machined can be positioned and fixed. The positioning plate is arranged on the machine tool or the worktable and used for positioning the installation bottom plate. By means of the fixture, the standard of upper end face and lower end face machining of the copper tube difficult to precisely position is ingeniously transferred to the fixture, and precise installation and positioning of the copper tube are guaranteed through the specially designed structure of the fixture. Accordingly, errors caused by a lineation method or a simple backer are avoided, it is guaranteed that machined parts are precise and reliable, product quality is improved, and defective products are reduced.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

One-way clutch bearing

ActiveCN106015389ACompact structureEasy to processBearing assemblyBall bearingsEngineeringMachining process

The invention relates to a one-way clutch bearing. In the axial direction, an outer ring and an inner ring are divided into a rolling body mounting section and a rolling needle mounting section; a roller path is arranged on the outer ring inner wall and the inner ring outer wall of the rolling body mounting section; a plurality of rolling bodies are arranged in the roller path on the outer ring and the inner ring; a rolling body holder is used for uniformly separating the plurality of the rolling bodies; a plurality of rolling needle groups are arranged between the outer ring inner wall and the inner ring outer wall of the rolling needle mounting section; a rolling needle holder is used for uniformly separating the plurality of the rolling needle groups; each rolling needle group comprises a first rolling needle and a second rolling needle; each first rolling needle and each second rolling needle are arranged in a holding slot of the rolling needle holding frame; a pressure angle is formed between a center connecting line of the first rolling needle and the second rolling needle and a contact pressure direction of the inner ring; each first rolling needle is positioned at the radial inner end of the holding slot, and is in contact with the outer wall of the inner ring; and each second rolling needle is positioned at the radial outer end of the holding slot, and is in contact with the inner wall of the outer ring. The one-way clutch bearing is simple and compact in structure, is good in processing process and is high in precision; and product quality is guaranteed.

Owner:WUXI NO 2 BEARING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com