Process for manufacturing quincuncial dowel screws

A double-ended screw and manufacturing process technology, applied in the field of plum-blossom double-ended screw manufacturing technology, can solve the problems of high processing cost, high processing time, affecting product quality and output, etc., to achieve reliable product quality assurance, reduce labor intensity, The effect of controlling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described below in conjunction with accompanying drawing.

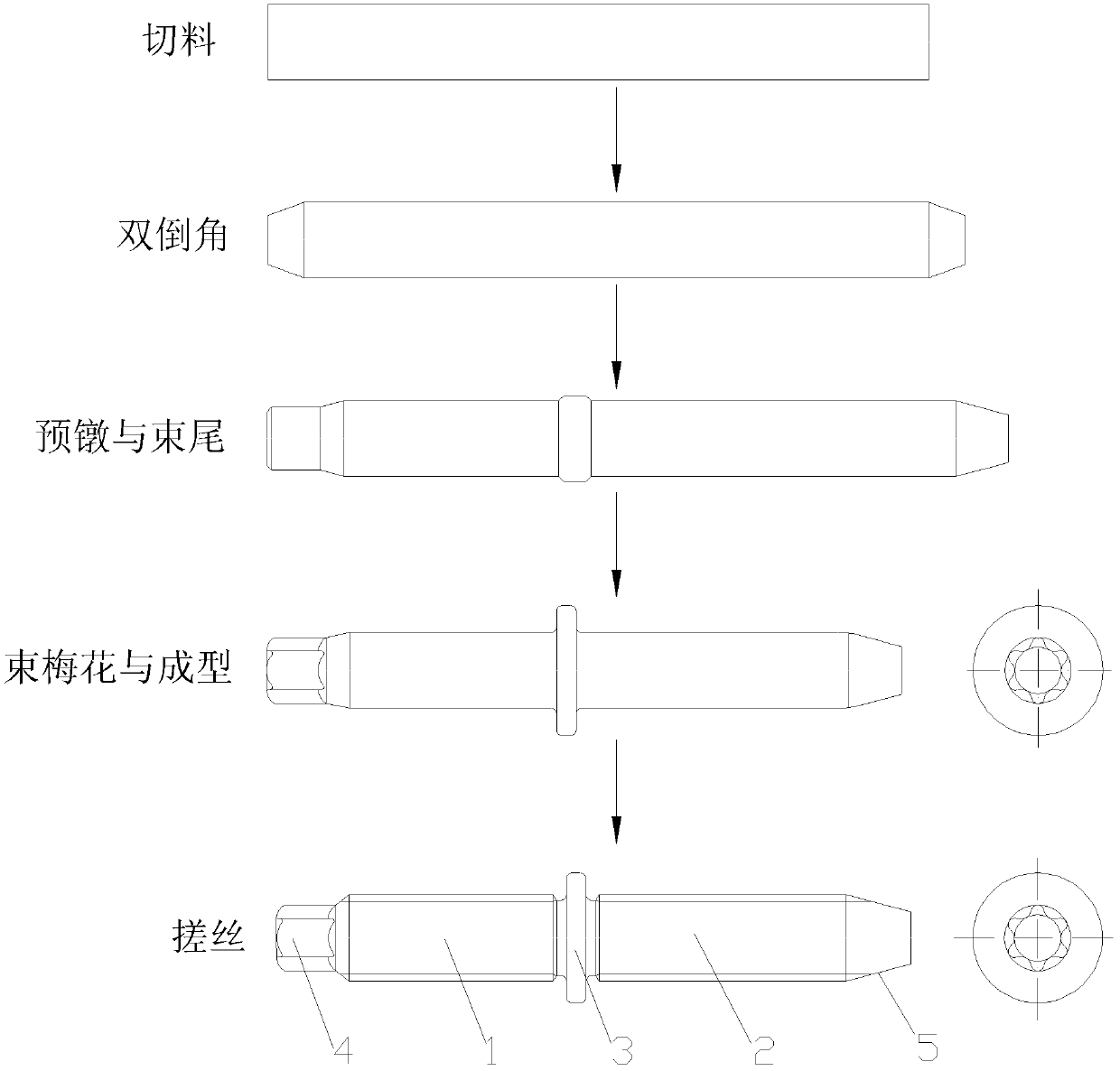

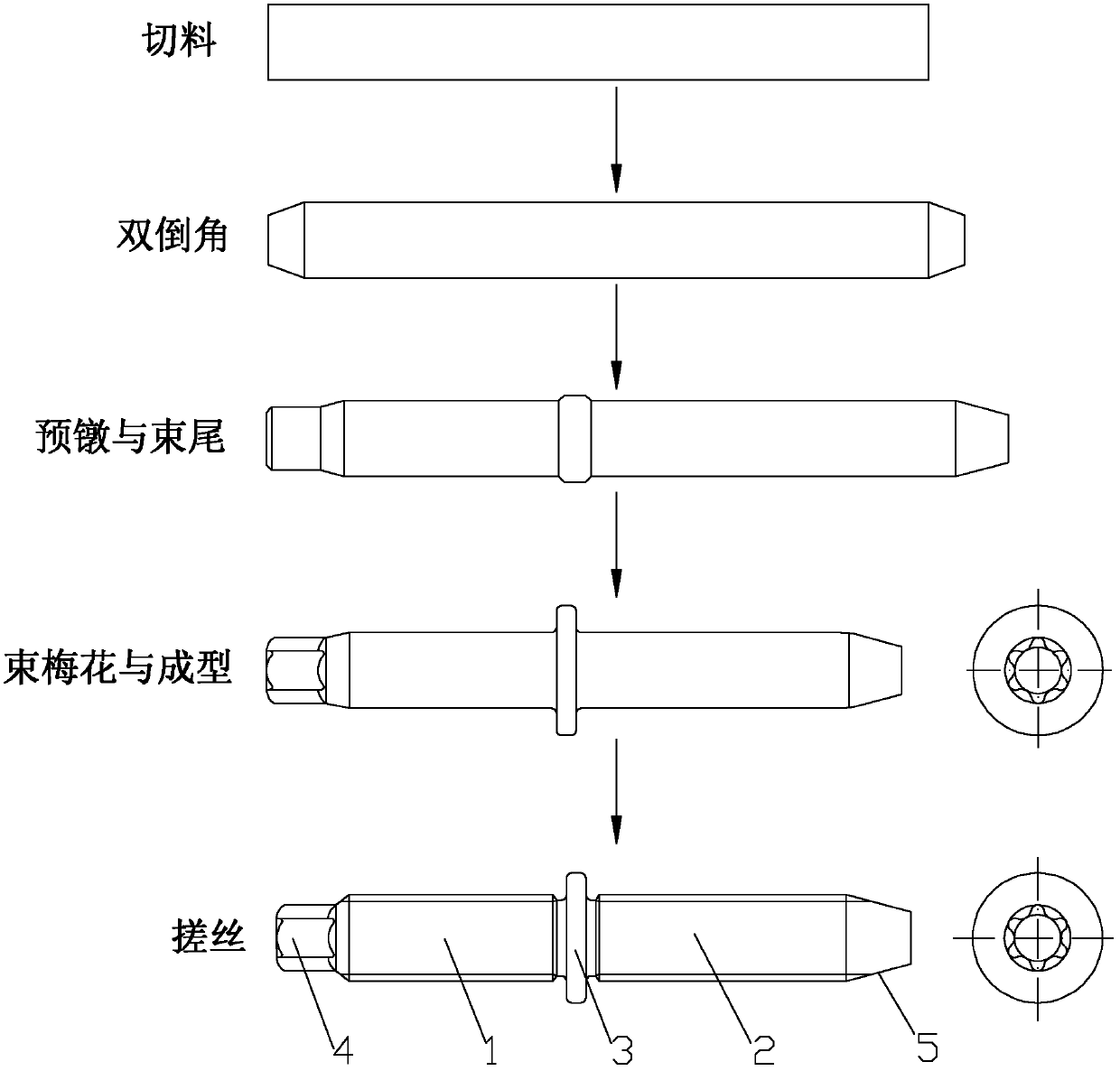

[0018] as attached figure 1 Shown is a kind of torx-shaped double-ended screw manufacturing process according to the present invention, which mainly includes the following steps:

[0019] (1) Cutting material: use a solid cylinder made of low-carbon martensitic steel as the raw material, and select a workpiece A with a diameter of 7mm and a length of 61mm according to the volume of the product after molding;

[0020] (2) Double chamfering: put the workpiece A obtained in step (1) into the mold of the first station cold heading machine, and perform round chamfering on both ends of the workpiece to obtain workpiece B;

[0021] (3) Pre-upsetting and bundle tail: Put the workpiece B obtained in step (2) into the mold of the second station cold heading machine, pre-upset the positioning boss, and squeeze out the tail from one end of the workpiece B to obtain the workpiece C;

[0022] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com