Special combined fixture for processing the upper and lower end faces of the copper tube of the round billet crystallizer and its application method

A crystallizer copper tube and end surface processing technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor manufacturing precision and low processing efficiency of the upper and lower end surfaces of copper tubes, so as to improve product quality and reduce The effect of waste and defective products and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

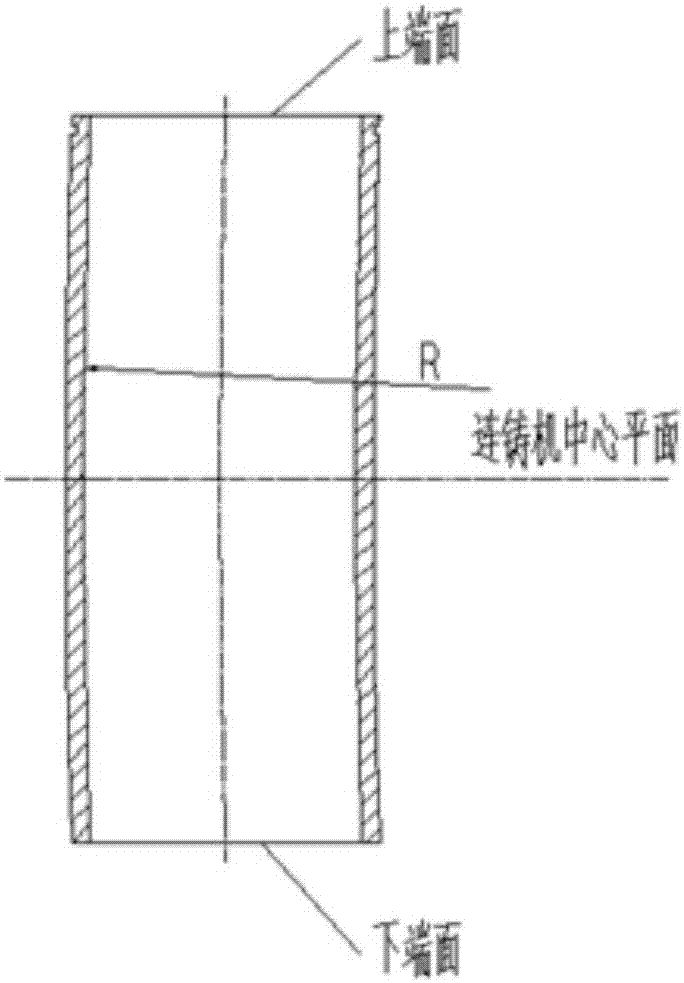

[0059] Preferred embodiment 1, an example of processing the upper and lower end faces of the φ280×780 crystallizer copper tube

[0060] skills requirement

[0061] Length 780±0.1

[0062] Copper tube outer diameter φ328

[0063] The parallelism of the upper and lower ends of the copper tube is 0.1

[0064] The parallelism between the upper and lower ends of the copper tube facing the central plane is 0.1

[0065] 1. Cut off the excess parts at both ends of the extruded copper pipe on a sawing machine, and the length is 790-800mm.

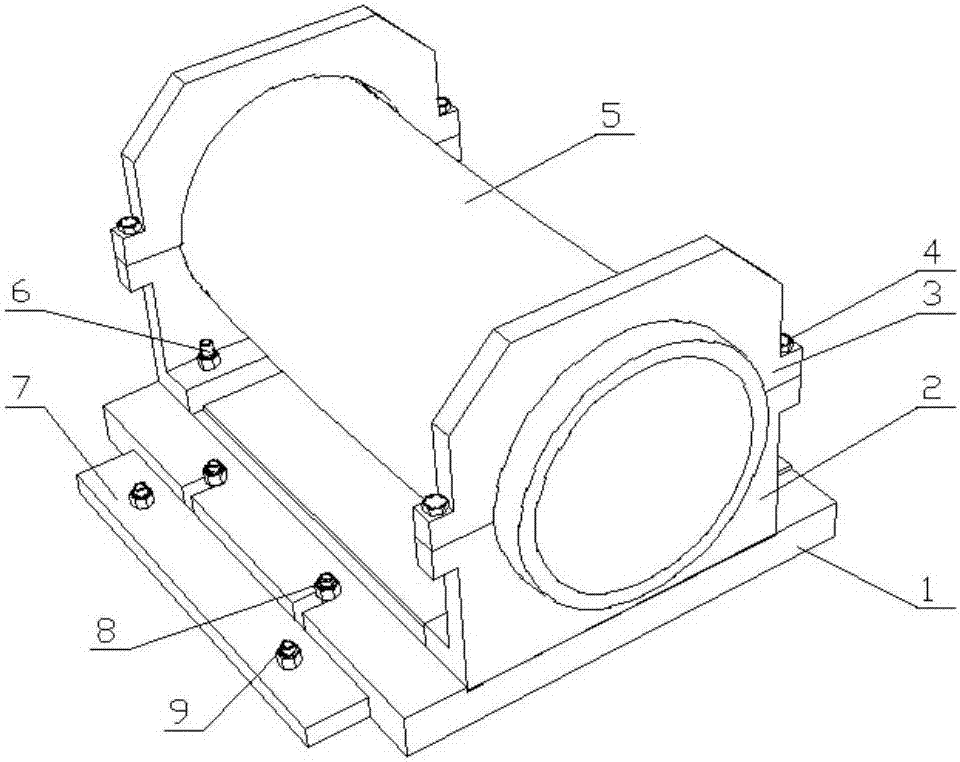

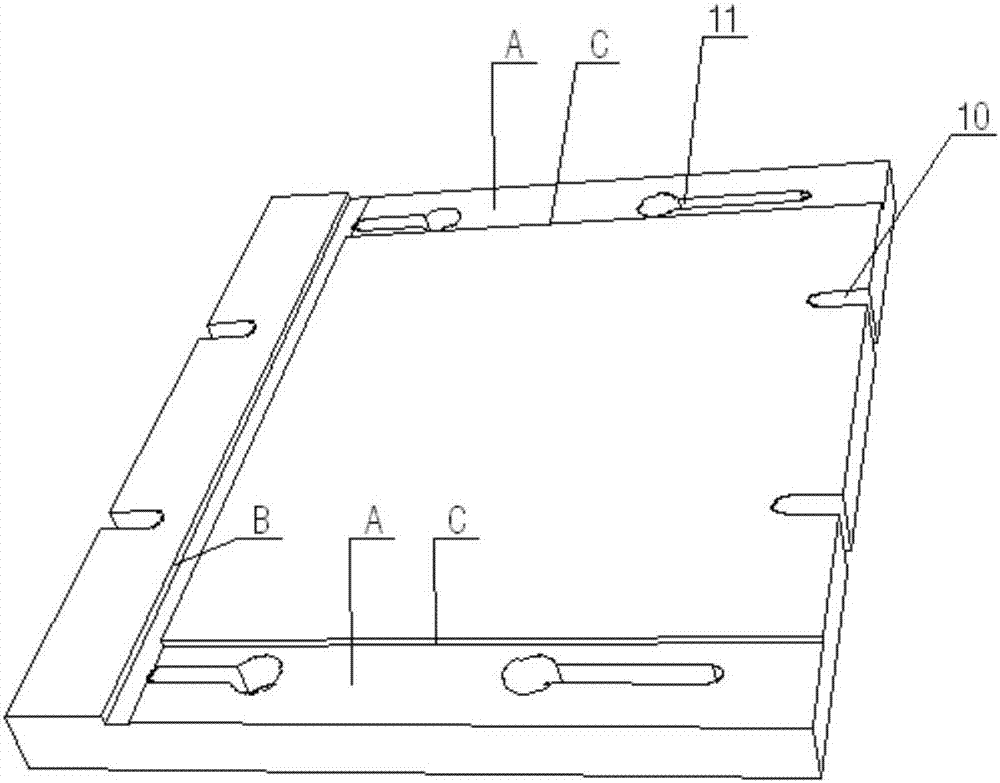

[0066] 2. Place the positioning plate 7 on the machine table, perform precise alignment, and fix it with screws 9.

[0067] 3. Press the combination fixture bottom plate figure 2 assembled and fixed on the machine table.

[0068] 4. Select the size of the central round hole as φ328 for the upper and lower clamping plates 2 and 3, install the lower clamping plate on the bottom plate 1 as shown in the figure, the flange edge is closely aligned ...

Embodiment 2

[0073] Preferred embodiment two, example of processing upper and lower end faces of φ330×800 crystallizer copper tube

[0074] skills requirement

[0075] Length 800±0.1

[0076] Copper tube outer diameter φ381

[0077] The parallelism of the upper and lower ends of the copper tube is 0.1

[0078] The parallelism between the upper and lower ends of the copper tube facing the central plane is 0.1

[0079] 1. Cut off the excess parts at both ends of the extruded copper tube on a sawing machine, and the length is 810-820mm.

[0080] 2. Select the upper and lower clamps with the center hole size as φ381, replace the upper and lower clamps with φ328 and fix them.

[0081] 3. Place the copper tube 5 to be processed in the semicircular groove of the lower clamping plate 2, so that the lengths of both ends of the copper tube are roughly equal, and use the upper clamping plate 3 and bolts 4 to clamp the copper tube 5 tightly.

[0082] 4. The two ends of the copper tube are process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com