Main feeder jumper manufacturing tooling and working method

A technology for manufacturing tooling and feeders, which is applied in the field of product automation manufacturing machine systems, can solve the problems of high probability of product appearance damage, frequent product transfer, and low production efficiency, and achieve an increase in per capita hourly production capacity, reduction in skills and labor intensity, and land occupation. The effect of less area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

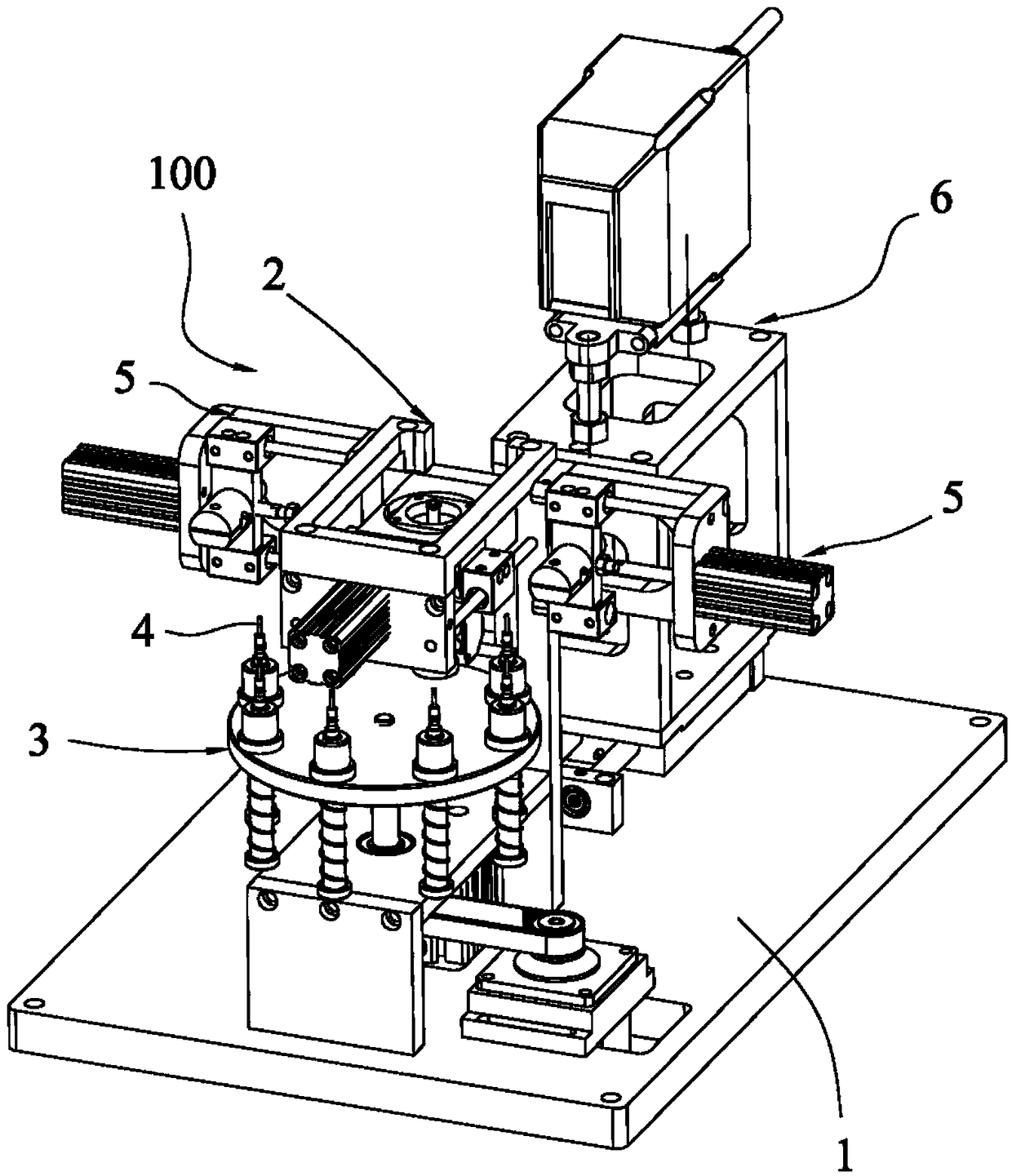

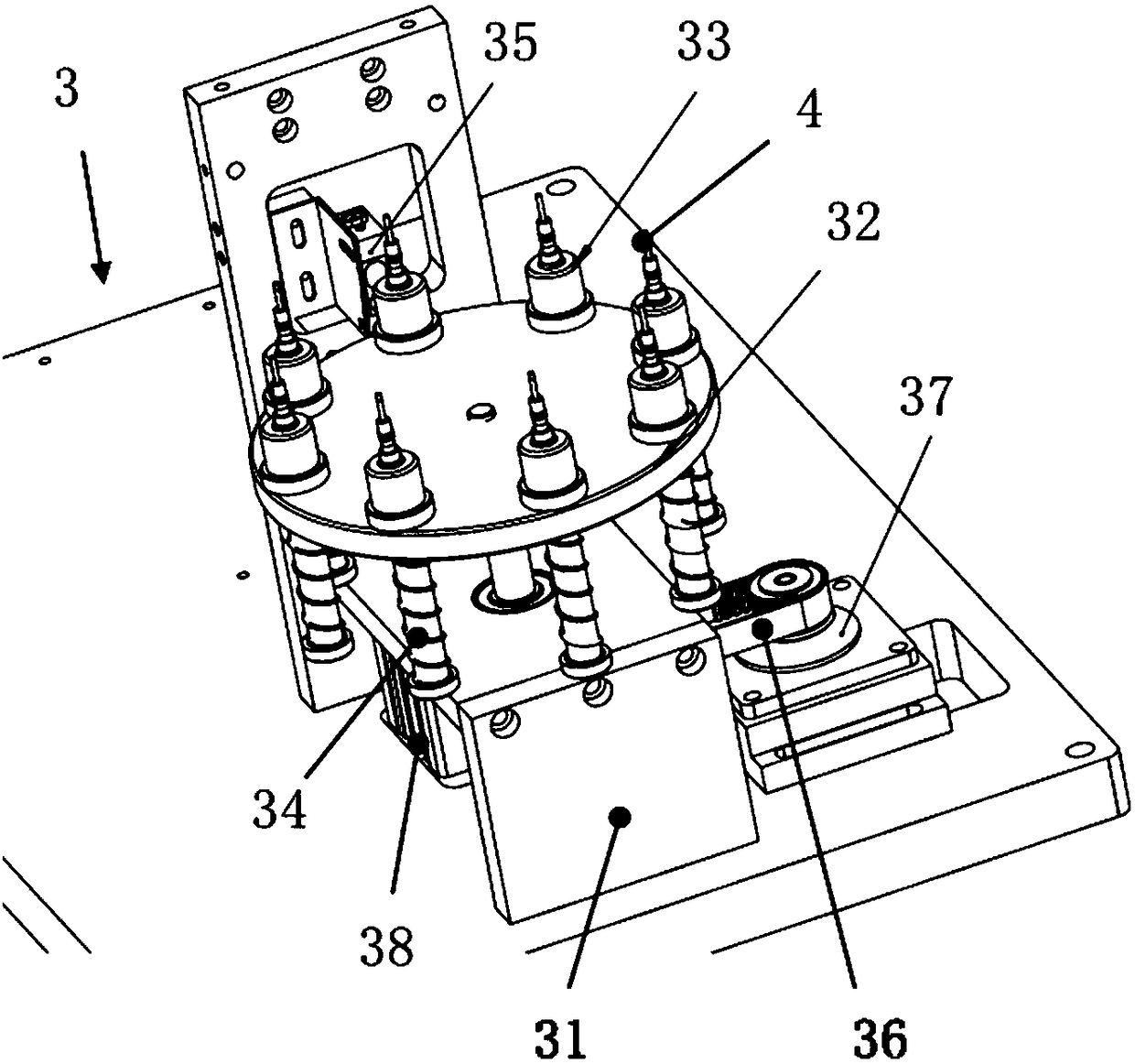

[0031] The manufacturing tooling device of the main feeder jumper for the mobile communication antenna of the present invention, such as figure 1 As shown, the manufacturing tooling device 100 of the main feeder jumper includes: a bottom plate 1, a clamping device 2, a placing and pressing device 3, a center conductor 4, at least one welding machine electrode opening and closing device 5, and a welding automatic shift device 6. , And control system. Among them, the clamping device 2, the placing and pressing device 3, the at least one welding machine electrode opening and closing device 5, and the welding automatic shift device 6 are all located on the bottom plate 1.

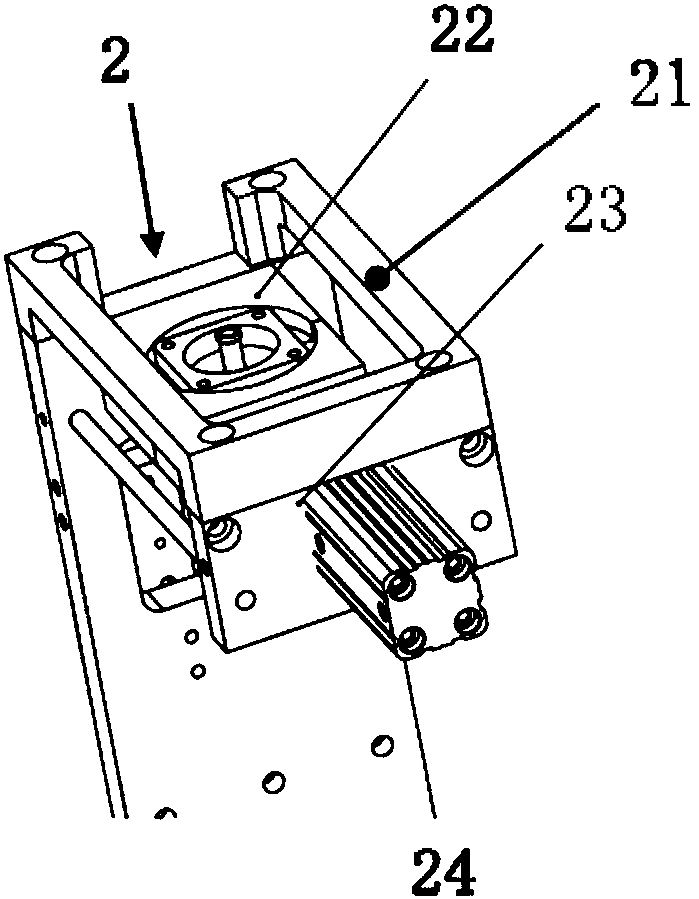

[0032] Such as figure 2 As shown, the clamping device 2 includes a housing 21, two cavity molds 22 located inside the housing 21 and nested together, and a displacement device 23, wherein the cavity mold 22 is designed according to the shape of the housing 21, and the cavity The mold 22 fixes the housing 21; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com